News

Comprehensive Analysis of the Advantages and Disadvantages of Capacitive Touch Screen: From Technical Principles to Practical Applications

Comprehensive Analysis of the Advantages and Disadvantages of Capacitive Touch Screen: From Technical Principles to Practical Applications

With the rapid advancement of human-machine interaction technologies, capacitive touch screen have become an indispensable interface across modern devices. They are widely used in smartphones, industrial control systems, medical equipment, automotive displays, and smart home devices. This article provides a thorough breakdown of the strengths and limitations of capacitive touch screen, helping readers better understand their technical characteristics and application scenarios.

I. Core Advantages of Capacitive Touch Screen

1. Highly Responsive Touch, Natural User Experience

Capacitive screens operate based on the electric current induced by the human body. They do not require pressure, only a light touch, offering a smoother and more intuitive interaction compared to resistive screens.

2. High Stability with Little to No Calibration Required

Unlike resistive touch screens, which often require periodic recalibration, capacitive screens typically need only one calibration during production—or none at all—significantly reducing maintenance time and effort.

3. No Moving Parts, Longer Lifespan

Capacitive screens use electrostatic fields to detect touch, meaning there are no mechanical components involved. This makes them more durable and ideal for high-frequency, intensive use environments.

4. Better Light Transmission and Lower Power Consumption

Compared to resistive technology, capacitive touch screens offer higher optical clarity and consume less power, resulting in clearer displays and improved energy efficiency.

5. Support for Multi-Touch and Gesture Control

Capacitive screens naturally support multi-touch input and gesture recognition, which greatly enhances interactivity and operational efficiency, especially in smartphones, tablets, and interactive kiosks.

6. Excellent Scratch Resistance and Low Maintenance

The outer surface is typically made of toughened glass (such as G+G structure), which is highly scratch-resistant and durable, making it suitable for harsh environments and reducing long-term maintenance costs.

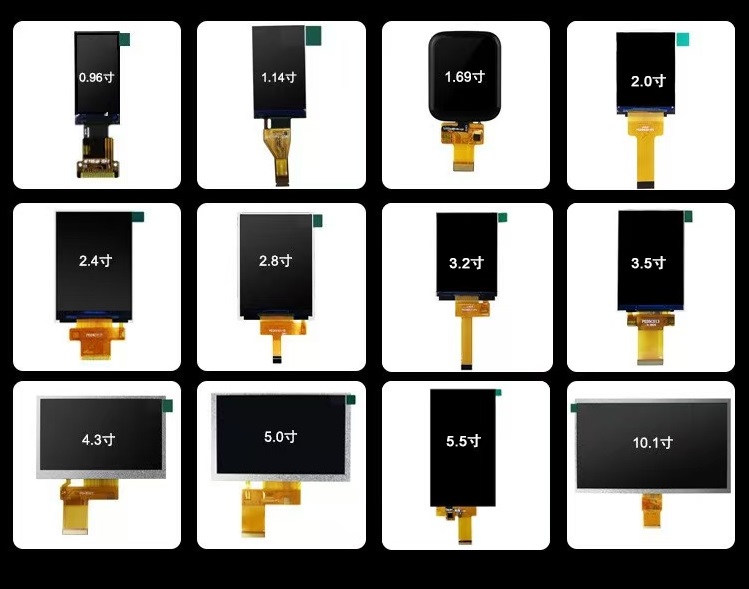

7. Adaptable for Various Screen Sizes

Surface capacitive technology is suitable for large screens, while projected capacitive technology excels in small to medium-sized screens—providing flexible options for a range of applications.

II. Potential Disadvantages and Challenges of Capacitive Touch Screen

1. Uneven Light Transmission and Color Distortion

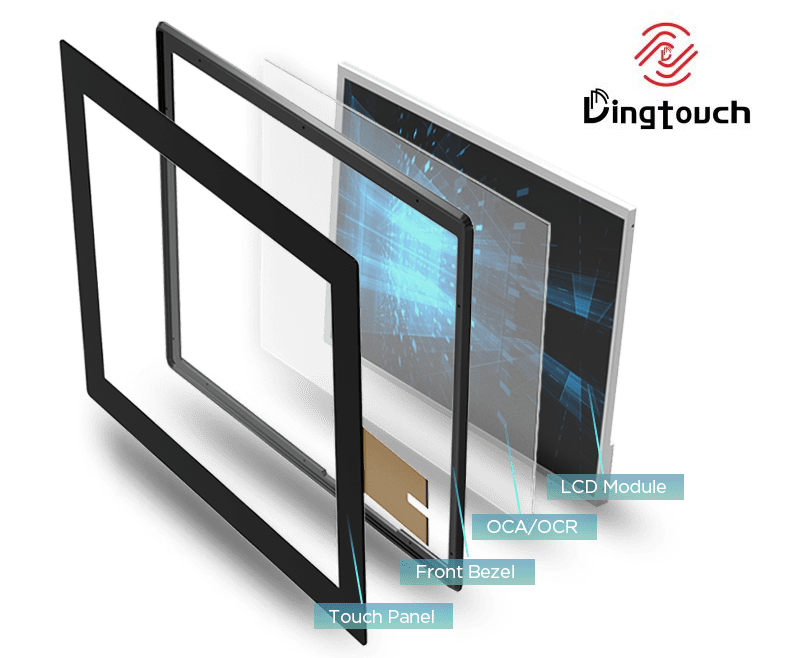

Due to the multi-layered composite structure (typically four layers), light reflection between layers can cause image blurring or uneven color rendering, which may impact visual quality.

2. Susceptibility to Electrical Interference and False Touches

Because capacitive screens use the human body as a conductor, nearby conductive objects can interfere with performance, potentially causing false touches. This issue is especially problematic in high-humidity environments. For example, if a user's hand is within 7 cm of the screen, or their body within 15 cm, unintended input may occur.

3. Unresponsive to Gloves or Non-Conductive Materials

Capacitive screens generally cannot detect touch through regular gloves or non-conductive tools (like a wooden or plastic stylus). A specialized capacitive stylus or conductive gloves are required.

4. Drift Issues Due to Environmental Changes

Capacitive screens can experience touch drift when surrounding temperature, humidity, or electromagnetic fields change. Common causes include: screen warming after power-up, user's body proximity, or movement of large nearby objects. These factors affect the screen’s ability to accurately locate touch points.

5. Complex Repair and High Cost of Damage

Though the outermost layer is scratch-resistant silicon dioxide glass, it is vulnerable to impact. A small crack or chip can damage the internal ITO layer, rendering the screen inoperable. Repairs are often costly and may require complete replacement.

6. Nonlinear Response and Complex Signal Processing

Capacitive screens translate electrical signals from four corners into Cartesian coordinates. This process is influenced by differences in users' finger size, moisture level, and body conductivity—resulting in nonlinear current values and complex calculations. Once drift occurs, the controller has no origin reference to recalibrate, requiring manual intervention in the field.

III. Technological Advancements and Future Trends

To address these disadvantages, the industry continues to innovate:

-

Improved Anti-Interference Algorithms: Enhanced IC software now adapts more effectively to environmental noise and electrical disturbances.

-

Advancement in Capacitive Styluses: Modern capacitive pens are more compatible and precise.

-

Glove-Touch Support: Technologies now allow capacitive screens to function with conductive gloves.

-

Material and Optical Enhancements: High-transparency glass, AR coatings, and optical bonding (OCA) have significantly improved brightness, visibility, and performance in bright environments.

IV. Application Advice and Selection Guidelines

When choosing a touch screen technology, consider the application needs and operating environment:

-

For precise stylus input → A resistive screen may be more appropriate.

-

For high-quality visuals and gesture control → Capacitive screens are the better choice.

-

For complex environments (wet hands, gloves, EMI) → A customized capacitive solution with enhanced anti-interference performance is recommended.

Conclusion

Capacitive touch screen are widely adopted due to their high responsiveness, durability, and support for multi-touch gestures. However, challenges such as environmental drift, sensitivity to interference, and limited compatibility with gloves still exist. Fortunately, ongoing innovations in materials, algorithms, and hardware are continuously improving performance. As a result, capacitive technology is expected to play an increasingly important role in advanced and professional display applications.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

Find the DINGTouch technical team to achieve the success of your company's new project.

What DINGTOUCH can do:

Dingtouch Industrial Capacitive Touch Screen Manufacturer

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch