News

A New Era of Touch: Innovative Comparison and Application Guide Between Resistive and Capacitive Touchscreens

A New Era of Touch: Innovative Comparison and Application Guide Between Resistive and Capacitive touchscreen

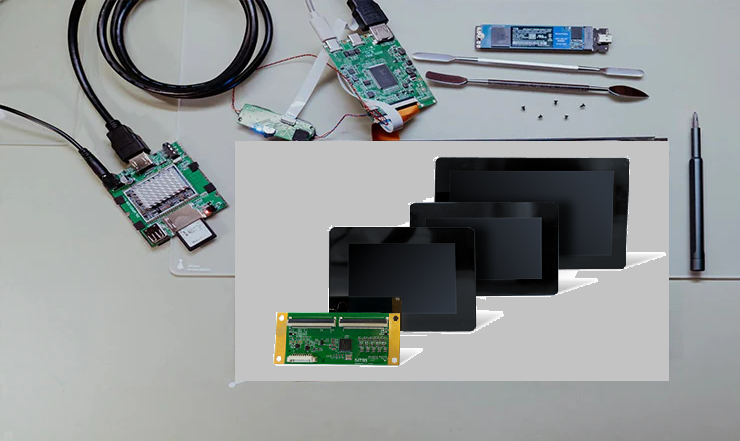

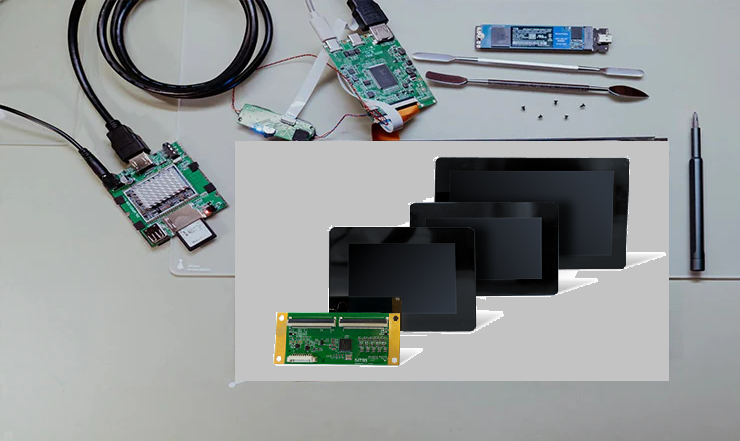

In today’s digital age, touchscreens have become more than just an interface—they are the bridge between people and technology. With the diversification of application scenarios and growing user expectations, choosing the right touchscreen—resistive or capacitive—has become a crucial early step in product development. This article takes an innovative perspective to re-examine these two mainstream touch technologies and help you make a smarter, scenario-specific decision.

1. The Essence of Touch: From "Pressure Detection" to "Electric Field Induction"

-

Resistive touchscreen operate based on pressure. Users press the screen with a finger, gloved hand, fingernail, or stylus, causing conductive layers to make contact and register the touch. Due to their simple structure and low cost, they are widely used in industrial control, medical equipment, and specialized terminals.

-

Capacitive touchscreen, on the other hand, rely on the body’s conductivity. When a finger touches the surface, it alters the electrostatic field, and the system calculates the touch point based on current variations. No pressure is needed, and gestures are smooth and intuitive. Capacitive screens dominate consumer electronics like smartphones and tablets.

✅ Innovation Insight:

Capacitive technology now supports glove mode and passive stylus input, overcoming its past limitations of not working with non-conductive materials.

2. Multi-Touch and User Experience: From "Clicking" to "Gesture Intelligence"

-

Capacitive touchscreen support multiple simultaneous touches, enabling smart gestures like pinch-to-zoom, rotate, or swipe. Coupled with AI, they can detect hand gestures or create virtual buttons, enhancing user experience.

-

Resistive touchscreen are limited by their design and can usually detect only one touch at a time. However, for single-point control tasks—such as in industrial or power control panels—they provide high reliability and low false-touch rates.

Trend Innovation:

High-precision pressure-sensitive resistive touch panels combined with machine learning can enable force-sensitive applications, such as in medical equipment or digital drawing tablets.

3. Environmental Adaptability: Which Screen Wins in the Real World?

-

Extreme Temperature/Humidity: Resistive screens remain reliable in cold and humid environments, making them ideal for outdoor and industrial use.

-

Durability and Cleanability: Capacitive screens, usually covered with hardened glass, are highly resistant to wear and easy to clean—perfect for frequent contact surfaces like medical or retail devices.

-

Contamination Tolerance: Resistive screens perform well even with water, oil, or dust—ideal for kitchens, fueling stations, and manufacturing environments.

Scenario Recommendation:

Outdoor Kiosks: Use resistive screens for better waterproof and dustproof performance.

High-End Consumer Devices: Capacitive screens offer superior aesthetics and smoother interaction.

Medical Equipment: Combine capacitive screens with anti-bacterial glass for hygiene and multi-touch capability.

4. Future Outlook: Integration and Customization Are the Way Forward

Rather than choosing one over the other, future touchscreen solutions will focus on scenario-based customization. Key trends include:

-

Capacitive + Active Stylus Hybrid: Enables precise input for industrial drawing and signature capture.

-

Flexible Touch Technology: Supports bendable and wearable devices.

-

AI-Assisted Touch: Detects accidental touches and understands user intent intelligently.

-

Environment-Aware touchscreens: Integrate temperature, pressure, or humidity sensors for contextual interaction.

Conclusion: No Absolute Winner—Only the Right Fit

Both resistive and capacitive touchscreens have their strengths. What matters most is understanding your product’s core function and usage environment. We recommend evaluating your needs across interaction type, environmental conditions, maintenance, and expandability to ensure your product stands out in the market.

If you're seeking a customized touchscreen solution tailored to your industry, our expert team is ready to help you unlock the perfect fit.

![]() Contact us: Sales@szdingtouch.com

Contact us: Sales@szdingtouch.com

![]() Official Website: www.szdingtouch.com

Official Website: www.szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch