News

How To Remove Glass From Lcd Screen?

How To Remove Glass From Lcd Screen?

Content Menu

● Tools and Materials Required

>> 5. Reapply New Glass (Optional)

● Additional Techniques for Difficult Screen

● Troubleshooting Common Issues

>> 1. Can I reuse the LCD after removing the glass?

>> 2. What temperature is safe for heating the adhesive?

>> 3. How do I handle heavily cracked glass?

>> 4. Is a hair dryer sufficient for manual separation?

>> 5. Can I replace only the glass without a separator machine?

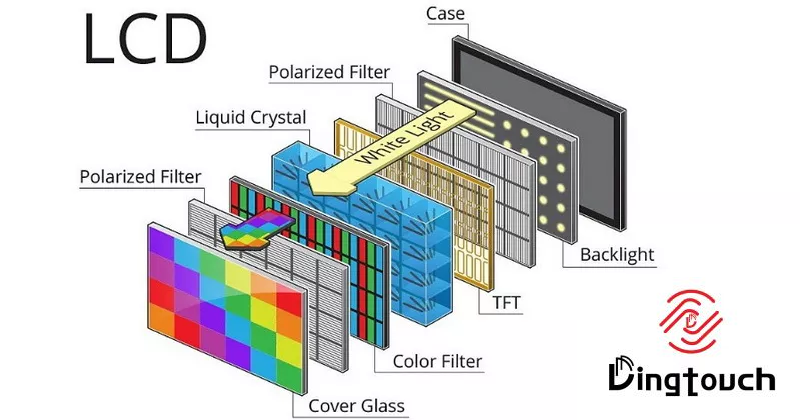

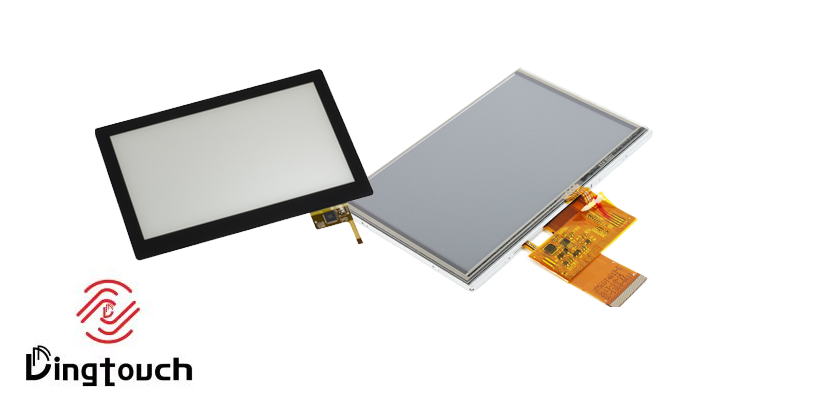

DINGTouch:Removing glass from an LCD screen is a delicate process often required for repairing smartphones, tablets, or laptops with cracked displays. This guide provides a detailed, step-by-step approach to safely separate the glass from the LCD using professional tools like separator machines and manual techniques.

Tools and Materials Required

Before starting, gather these essentials:

- LCD separator machine (manual or automated)

- Heat gun/hair dryer (for manual methods)

- Suction cups and pry tools

- Molybdenum wire or thin thread (0.08–0.1 mm thickness)

- Isopropyl alcohol (for cleaning adhesive)

- Safety gear: Heat-resistant gloves, goggles

- Replacement glass/OCA adhesive (if reapplying)

Step-by-Step Guide

1. Prepare the Work Area

Ensure a clean, dust-free workspace. Secure the device to a stable surface using clamps or a vacuum holder. Proper lighting is also essential to see any small components clearly.

2. Heat the Adhesive

Set the separator machine to 80–120°C depending on the device model. For manual methods, use a heat gun at 70–80°C to soften the adhesive. Heat the edges of the glass for 2–5 minutes to ensure it becomes pliable without damaging the LCD beneath.

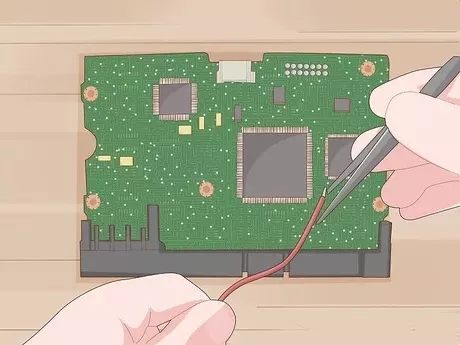

3. Separate the Glass

Using a Separator Machine:

Place the device on the machine's platform and activate the vacuum suction. Thread the molybdenum wire between the glass and LCD, using diagonal movements to slice through the adhesive. Gradually increase pressure until the glass lifts away without resistance.

Manual Method:

Slide a thin blade or playing card under the heated glass edge. Work the tool around the perimeter, reapplying heat as needed to keep the adhesive soft.

4. Clean Residual Adhesive

Use isopropyl alcohol and a microfiber cloth to remove leftover glue from both the LCD and any remaining pieces of glass. This step is crucial to ensure a smooth surface for any new glass or adhesive application.

5. Reapply New Glass (Optional)

Align replacement glass with the LCD and use a laminator to bond it securely. Cure the adhesive with UV light for 10–15 minutes to ensure it sets properly without bubbles.

Common Mistakes to Avoid

1. Overheating: Excessive heat can damage the LCD polarizing layer, leading to display issues post-repair.

2. Rushing the Process: Forcing separation risks cracking not only the glass but also damaging internal components.

3. Skipping Safety Gear: Glass shards can cause injuries; always wear protective eyewear and gloves.

Additional Techniques for Difficult Screen

In some cases, screen may be particularly stubborn due to excess adhesive or previous repairs that have left residue behind. Here are some advanced techniques:

- Use of Acetone: In cases where adhesive is exceptionally strong, applying acetone can help dissolve it more effectively than isopropyl alcohol.

- Ultrasonic Cleaners: These devices can be used to gently vibrate and loosen adhesives without damaging sensitive components.

- Vibration Tools: Some technicians use vibration tools that can help in loosening stubborn adhesives by providing gentle oscillations.

Troubleshooting Common Issues

While performing this procedure, you may encounter several common issues:

- Glass Does Not Separate Easily: If you find that despite heating, the glass does not separate easily, it may require additional heat or you may need to apply more pressure gradually.

- LCD Display Damage: If you accidentally crack the LCD during removal, you will need to replace it entirely rather than just replacing the glass.

- Residual Adhesive: If there's significant leftover adhesive that doesn't come off easily, consider using specialized adhesive removers designed for electronics.

Conclusion

Removing glass from an LCD requires precision, patience, and the right tools. While separator machines offer efficiency and consistency, manual methods are viable for small-scale repairs when done carefully. Always prioritize safety and follow manufacturer guidelines for temperature and pressure settings to avoid damaging sensitive components.

Related Questions

1. Can I reuse the LCD after removing the glass?

Yes, if the LCD is undamaged during separation. Clean residual adhesive thoroughly before reassembly.

2. What temperature is safe for heating the adhesive?

Most devices require temperatures between 80–120°C; exceeding this may discolour or damage components.

3. How do I handle heavily cracked glass?

Use a wire separator to avoid pulling large shards; heat small sections incrementally for better control.

4. Is a hair dryer sufficient for manual separation?

Yes, but it may take longer; ensure even heat distribution to prevent hotspots that could damage components.

5. Can I replace only the glass without a separator machine?

Yes, but manual methods have a higher risk of damaging the LCD; practice on broken screens first if possible.

By following these guidelines, you can safely remove glass from an LCD screen, whether for repairs or part replacement. Always test functionality before reassembling devices to ensure everything operates correctly after repairs are made.

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch