News

Impact of High Temperatures on Wide-Temperature LCD: Mechanisms, Lifespan Management, and Future Innovations

Impact of High Temperatures on Wide-Temperature LCD: Mechanisms, Lifespan Management, and Future Innovations

1. Definition and Features of Wide-Temperature LCD

Wide-temperature LCD are specialized display devices designed for extreme environments, typically offering operating ranges of -20℃~70℃, -30℃~80℃, or even wider. Compared to standard LCD, wide-temperature LCDs can maintain smooth display performance under low temperatures and stable operation in high-temperature conditions. They are widely used in industrial automation, outdoor equipment, transportation, and military applications.

However, despite their strong temperature tolerance, prolonged exposure to high temperatures can still lead to performance degradation and reduced lifespan, which is a critical concern in demanding environments.

2. Mechanisms of High-Temperature Effects on Wide-Temperature LCD

2.1 Display Degradation

-

Liquid Crystal Instability: Elevated temperatures accelerate the movement of liquid crystal molecules, reducing alignment precision and resulting in blurred images or color shifts.

-

Brightness Reduction: The quantum efficiency of backlight phosphors decreases under high temperatures, leading to dimmer displays, especially under direct sunlight.

-

Contrast Loss: High temperatures impair the electro-optical response of liquid crystals, reducing black-and-white contrast and diminishing grayscale performance.

2.2 Structural Damage

-

Sealant Aging: Adhesives and polarizers soften or crack under heat, causing light leakage and dust ingress.

-

Circuit Failure: Overheating can lead to solder joint loosening, IC malfunction, or short/open circuits.

-

Glass Substrate Stress: Repeated thermal expansion and contraction may create microcracks, compromising mechanical stability.

2.3 Material Degradation and Lifespan Reduction

-

Organic Layer Oxidation: Polarizers and color filters deteriorate faster, distorting color accuracy.

-

Metal Trace Corrosion: Heat coupled with humidity accelerates oxidation of internal metal traces, reducing conductivity.

-

Shortened Lifespan: Combined effects speed up material fatigue, reducing the LCD Mean Time Between Failures (MTBF).

3. Lifespan Management and Extension Strategies in High-Temperature Environments

3.1 Active Cooling Techniques

-

Built-in Micro Fans: Ideal for enclosed industrial cabinets or high-heat systems.

-

Thermal Conduction Design: Use aluminum enclosures with heat pipes or graphite pads for rapid heat dissipation.

-

Smart Thermal Control: Integrate temperature sensors and PWM control to automatically adjust backlight brightness and cooling fan speed.

3.2 Environmental Optimization

-

Sunlight Protection: Use sunshades or anti-UV coatings for outdoor installations.

-

Ventilation Design: Ensure unobstructed airflow paths to prevent overheating.

-

Heat Source Isolation: Keep LCD away from motors, heaters, and other high-power heat sources.

3.3 Preventive Maintenance and Inspection

-

Thermal Cycling Tests: Periodically test display circuits and backlight stability under heat stress.

-

Cleaning and Upkeep: Remove dust and oil residues to keep ventilation pathways clear.

-

Material Replacement: Replace aging polarizers or sealants in long-term high-heat applications.

4. Industry Solutions and Innovations

4.1 Industrial and Outdoor Equipment

-

Integrate wide-temperature LED backlights with high-conductivity graphite-based heat dissipation.

-

Use automatic brightness adjustment to reduce heat buildup during high-temperature operation.

4.2 Transportation and Military Applications

-

Employ double-glass with vacuum insulation layers to block external thermal radiation.

-

Utilize low-power TFT-LCD driver ICs to minimize heat generation.

4.3 Future Technology Trends

-

MicroLED Adoption: Offers superior brightness, power efficiency, and thermal stability.

-

Nano Thermal Coatings: Reduce surface temperature through advanced nano-materials.

-

AI-Powered Thermal Management: Real-time adaptive cooling and brightness regulation via intelligent algorithms.

5. Conclusion

While wide-temperature LCD are designed to operate across extended temperature ranges, prolonged high-temperature exposure remains a key risk factor for performance degradation and reduced lifespan.

By implementing optimized thermal design, environmental control, smart temperature regulation, and preventive maintenance, the reliability and service life of wide-temperature LCD can be significantly improved.

Looking ahead, the integration of MicroLED technology, AI-driven thermal management, and advanced cooling materials will further enhance the durability and performance of LCD in harsh high-temperature environments.

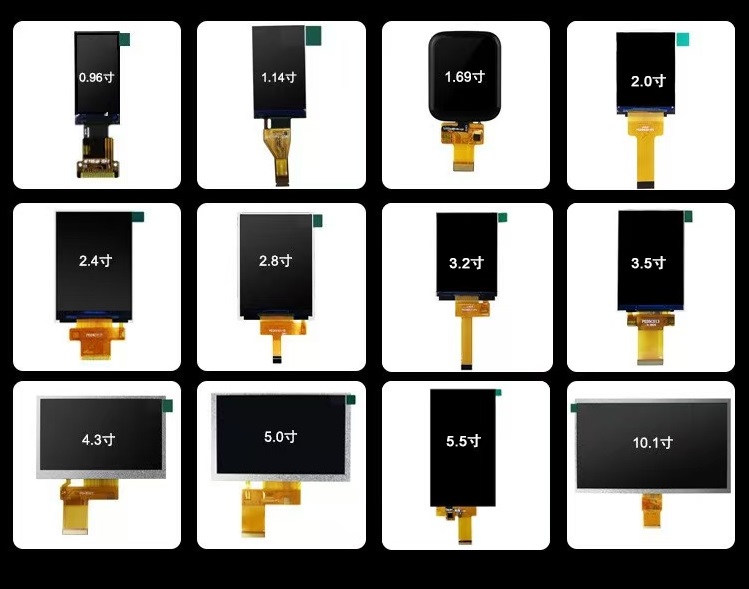

DINGTouch provides fully customizable wide temperature display modules—from 2.8” to 23.8”up to 65”, with flexible interfaces, touch options, optical bonding, and ruggedization. Let us help you build the display solution that’s ready for any environment, anytime.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedical display, #touchscreenaccuracy, #touchscreen drift fix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch