News

What are the standards for medical grade monitors?

What are the standards for medical grade monitors?

Standards for medical-grade displays are often very stringent to ensure their accuracy, reliability and safety in diagnostic medical imaging and clinical settings. Here are some of the standards and requirements that medical-grade monitors typically need to meet:

DICOM standard: Medical-grade displays need to comply with the Digital Imaging and Communications in Medicine (DICOM) standard to ensure that they can correctly display medical images, such as X-rays, CT scans, MRI images, etc., and can accurately present grayscale levels to meet Requirements for medical imaging diagnosis.

Low radiation: Medical-grade displays usually need to comply with relevant international standards in terms of radiation to ensure that they have no radiation or very low radiation to minimize the impact on medical staff and patients.

Protective performance: Medical-grade displays usually need to have protective properties, including antibacterial, waterproof, dustproof and other functions, to cope with the special needs of the medical environment and ensure that they are easy to clean and maintain.

Calibration and stability: Medical-grade monitors need to have good calibration performance and long-term stability to ensure that they can provide accurate and reliable image display for a long time and will not change significantly during long-term use.

Safety certification: Medical-grade displays usually need to pass relevant safety certification and medical device registration to ensure that they comply with the laws, regulations and quality management system requirements of the medical industry, and have corresponding safety performance.

Generally speaking, medical-grade displays have strict standards and requirements, aiming to ensure the accuracy and safety of medical imaging diagnosis, as well as meet the special needs in the medical environment.

A medical-grade display is a display device designed and manufactured to meet specific standards and requirements for use in medical environments. These monitors play a vital role in healthcare environments, where accurate and reliable visual information is critical for diagnostic and patient care purposes. The designation "Medical Grade" means these monitors adhere to strict guidelines to ensure accuracy, consistency and safety for medical imaging and healthcare applications.

Regulatory Compliance: Medical-grade monitors must meet various regulatory standards and certifications to ensure they are suitable for use in healthcare environments. Organizations such as the U.S. Food and Drug Administration (FDA) and the International Electrotechnical Commission (IEC) develop guidelines for medical devices, including monitors. Compliance with electrical safety standards such as IEC 60601-1 is critical to ensuring the protection of patients and healthcare professionals.

Image Quality and Accuracy: One of the key features of medical-grade monitors is their superior image quality and accuracy. These displays are designed to display medical images, including X-rays, MRIs, CT scans, and other high-precision diagnostic imaging. They typically have higher resolution, better color reproduction and grayscale capabilities than consumer-grade displays, ensuring healthcare professionals can accurately interpret and analyze medical images.

Calibration and Consistency: Medical-grade monitors undergo a rigorous calibration process to ensure images display consistently and accurately over time. Calibration is critical to maintaining uniform brightness, contrast, and color accuracy throughout the lifetime of your monitor. Periodic recalibration is often required to account for potential drift and performance changes and ensure the monitor remains reliable for diagnostic purposes.

Compliant with DICOM standards: The Digital Imaging and Communications in Medicine (DICOM) standard is widely used for the storage and communication of medical images. Medical-grade monitors are typically DICOM compliant, which means they follow specific standards for displaying grayscale images. This compliance ensures that the monitor can accurately represent the different gray tones in medical images, allowing healthcare professionals to make accurate diagnoses.

Anti-glare and anti-reflective coatings: To improve visibility under various lighting conditions and reduce reflections, medical-grade monitors often have anti-glare and anti-reflective coatings. These coatings minimize interference caused by ambient light, ensuring healthcare professionals can focus on the details of medical images without interruption.

Infection control and durability: In healthcare facilities, monitors must be durable and able to withstand regular cleaning and disinfection to maintain environmental hygiene. Medical-grade monitors are typically designed with sealed surfaces and rugged materials that can withstand cleaning agents without affecting performance. This is crucial to prevent the spread of infection in clinical settings.

Ergonomic design: Medical-grade monitors are often designed with the ergonomic needs of healthcare professionals in mind. Adjustable stands, swivel options, and the ability to swivel the screen allow for optimal positioning, reducing stress and fatigue during long working hours. This ergonomic design contributes to the overall well-being of healthcare practitioners and increases their productivity.

Redundancy and Reliability: In critical healthcare applications, reliability is critical. Medical-grade monitors often employ redundant systems and fail-safe mechanisms to minimize the risk of failure. Redundant power supplies and advanced diagnostics help improve the overall reliability of these monitors in high-risk medical environments.

In summary, medical-grade monitors stand out among consumer monitors due to their compliance with strict regulations, superior image quality, calibration processes, compliance with DICOM standards, and features designed for infection control and durability. These displays play a vital role in healthcare, providing accurate and reliable visual information for diagnostic and patient care purposes, helping to improve medical outcomes and patient safety.

Contact DINGTOUCH today to learn how a display supplier can offer your business the benefits of powerful customization for automation applications.

We at DINGTOUCH will analyze and solve this problem based on the corresponding situation. DINGTOUCH Touch screen manufacturers have many years of industry experience. We focus on Touch screen R&D and design and support customization with samples and drawings.

Do you know what other standards are for medical device touch screens?

You can discuss and chat together.

DINGTOUCH: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTOUCH is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTOUCH: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

How to choose touch screen customization?

Find the DINGTOUCH technical team to achieve the success of your company's new project.

DINGTOUCH is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTOUCH is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

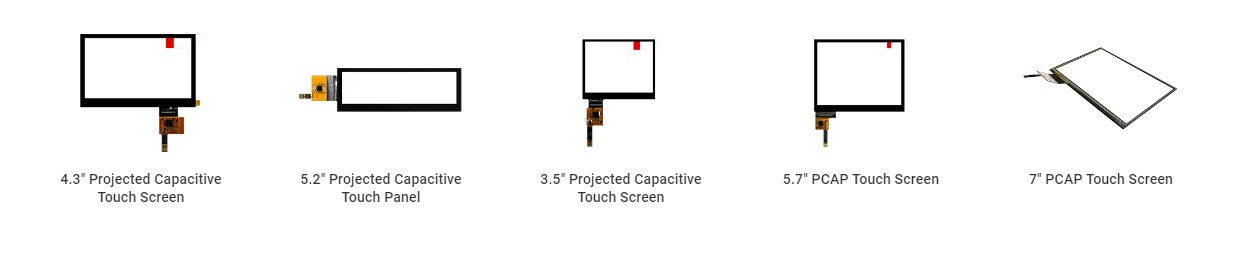

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch