News

Suitable Industrial Equipment Control TFT Display

Suitable Industrial Equipment Control TFT Display

In the ever-evolving world of industrial automation, the role of display technology is paramount. Among the various types of displays available, Thin-Film Transistor (TFT) displays have gained significant attention due to their advanced features, high-quality visuals, and versatility. A suitable industrial equipment control TFT display can make a remarkable difference in the efficiency, safety, and overall performance of machinery. This article will explore the benefits, applications, and essential features of TFT display used in industrial settings, along with best practices for selecting the right display for your equipment.

What is a TFT Display?

TFT (Thin-Film Transistor) display are a type of liquid crystal display (LCD) that utilizes thin-film transistor technology to improve image quality, response time, and color accuracy. TFT displays are capable of showing high-definition images, which makes them an ideal choice for industries that require sharp, clear, and vibrant visual outputs.

Key Features of TFT Display

TFT display offer a wide array of advantages that make them suitable for industrial control systems. Some of the key features include:

- High Resolution: TFT display are known for their high pixel density, which enables them to provide clear and detailed images, even in complex control systems.

- Wide Viewing Angles: The technology allows for better visibility from various angles, which is particularly useful in industrial settings where operators may not always be directly in front of the display.

- touchscreen Capability: Many modern TFT display come with touch-sensitive surfaces, allowing for direct user interaction and improved control.

- Fast Response Time: Industrial processes often require real-time monitoring and adjustments. TFT display feature quick response times, making them suitable for fast-paced environments.

- Durability: TFT displays are built to withstand harsh industrial environments, including exposure to high temperatures, humidity, and vibrations.

Importance of TFT Display in Industrial Control Systems

Industrial control systems, which manage machinery and processes in sectors such as manufacturing, energy, and automation, rely heavily on accurate and timely information. A TFT display, as part of the human-machine interface (HMI), provides operators with real-time data, allowing them to monitor and control processes more effectively.

Enhanced User Interface

A clear and responsive display enhances the user experience by providing a comprehensive interface for operators. With high-resolution TFT display, operators can view detailed information such as system status, warnings, and alerts with ease. This makes it possible to troubleshoot and react swiftly to any potential issues, reducing downtime and enhancing productivity.

Real-Time Monitoring and Control

In industrial environments, process optimization and constant monitoring are essential. TFT display allow for real-time monitoring of equipment performance, enabling operators to make timely adjustments. They also provide valuable data that can be used to forecast issues and improve overall efficiency.

Remote Management Capabilities

Some TFT display can be integrated into remote monitoring systems, providing operators with the ability to control and manage equipment from a distance. This is particularly beneficial in large industrial plants or facilities where centralized monitoring is necessary to oversee multiple operations.

Applications of TFT Display in Industrial Equipment Control

The versatility of TFT display has led to their widespread use across various industries. Below are some examples of how TFT display are integrated into industrial equipment control.

Manufacturing Plants

In manufacturing plants, TFT display are used to monitor and control machines on the production line. These displays provide real-time data on machine performance, production speed, and error reporting. With a user-friendly interface, operators can adjust machine settings and make necessary changes to ensure optimal performance.

Energy Sector

In the energy industry, particularly in power plants, TFT display are used to track energy production, monitor equipment health, and maintain system stability. The high-definition visuals and real-time feedback provided by TFT displays are essential for operators to quickly identify problems and ensure continuous energy flow.

Automotive Industry

The automotive industry relies on TFT display for both operational control and vehicle diagnostics. From monitoring assembly lines to diagnosing vehicle performance, TFT displays provide an essential means of interaction between operators and machinery. TFT touchscreens are increasingly used in modern vehicles for in-car infotainment systems as well.

Food and Beverage Processing

In the food and beverage sector, controlling environmental conditions, such as temperature and humidity, is crucial for maintaining product quality. TFT display are often used to monitor these variables in real-time and provide feedback to operators, helping to ensure that production standards are met.

Oil and Gas Industry

The oil and gas industry also benefits from TFT display, which are used in offshore platforms, refineries, and pipelines for control and monitoring purposes. TFT display provide operators with essential data on pressure, temperature, and flow rates, ensuring that operations are running smoothly and safely.

Factors to Consider When Choosing an Industrial Control TFT Display

When selecting a TFT display for industrial control systems, there are several factors that should be considered to ensure optimal performance and long-lasting reliability.

Display Size and Resolution

The display size and resolution are critical factors in determining how much information can be shown on the screen. Larger screens with higher resolutions allow for more detailed visuals, which are especially important in complex systems where multiple parameters need to be monitored simultaneously.

- Size: Choose a display size that fits the control panel or area where it will be installed. Consider the space available and the proximity of the operator to the display.

- Resolution: Higher resolution displays (such as Full HD or 4K) provide more details and are essential for systems requiring precise and clear visuals.

Durability and Environmental Resistance

Industrial environments can be harsh, with factors like temperature extremes, moisture, dust, and vibrations posing challenges to electronic devices. TFT display designed for industrial use are often built to withstand these conditions. Ensure that the display is rated for the specific environmental factors it will face.

- Temperature Range: Industrial TFT display are available in various temperature ranges. It’s essential to choose one that can operate effectively in the expected conditions, whether that’s in a hot factory floor or a cold storage environment.

- Ingress Protection (IP): Look for displays with an appropriate IP rating to protect against dust and water ingress, particularly if the display will be exposed to these elements.

- Vibration Resistance: If the equipment will be subject to vibrations, it’s important to select a TFT display with enhanced durability, capable of withstanding mechanical shocks without compromising performance.

Connectivity and Integration

In modern industrial settings, displays are often integrated into larger systems that involve sensors, controllers, and other machinery. Therefore, connectivity is a crucial factor when selecting a TFT display. Look for displays with multiple input options such as HDMI, VGA, DisplayPort, and even wireless connectivity, depending on your needs.

- Serial Communication: Industrial control systems often use serial communication protocols like RS-232, RS-485, and Modbus. Ensure that your TFT display supports the necessary interfaces.

- touchscreen and HMI Integration: For more interactive control, consider displays that integrate with HMI systems, allowing users to interact with machinery settings directly through the screen.

Advantages of touchscreen TFT Display in Industrial Equipment Control

One of the most significant innovations in TFT display for industrial use is the incorporation of touchscreen technology. touchscreens provide operators with direct and intuitive control over equipment, improving usability and increasing operational efficiency.

Improved Operator Efficiency

touchscreen displays simplify the operation of complex systems by offering a more direct and user-friendly method of interaction. Operators can make adjustments and navigate through menus with just a few taps, reducing the time spent on manual controls and minimizing the chances for human error.

Space Efficiency

The integration of touch functionality into TFT display eliminates the need for external buttons or switches, freeing up space and reducing clutter. This is particularly beneficial in industrial control panels where space may be limited, allowing for a cleaner and more organized interface.

Remote Control Features

Advanced TFT touchscreen displays can also offer remote control features, allowing operators to adjust settings or view system data from a distance. This is useful in large plants or facilities where operators are not always located near the equipment they are monitoring.

Conclusion

TFT display have emerged as a crucial component of industrial control systems, providing clear, real-time information that is essential for smooth and efficient operations. Their high resolution, durability, and versatile connectivity options make them ideal for use in a variety of industrial sectors. Whether it’s monitoring production lines, controlling energy systems, or managing machinery in hazardous environments, a suitable TFT display can significantly enhance performance and ensure the safety of operations.

By considering factors such as display size, environmental resistance, and connectivity options, businesses can select the right TFT display for their industrial equipment control needs. As technology continues to advance, the role of TFT display in industrial automation is set to expand, offering even more capabilities for optimizing workflows and improving operational outcomes.

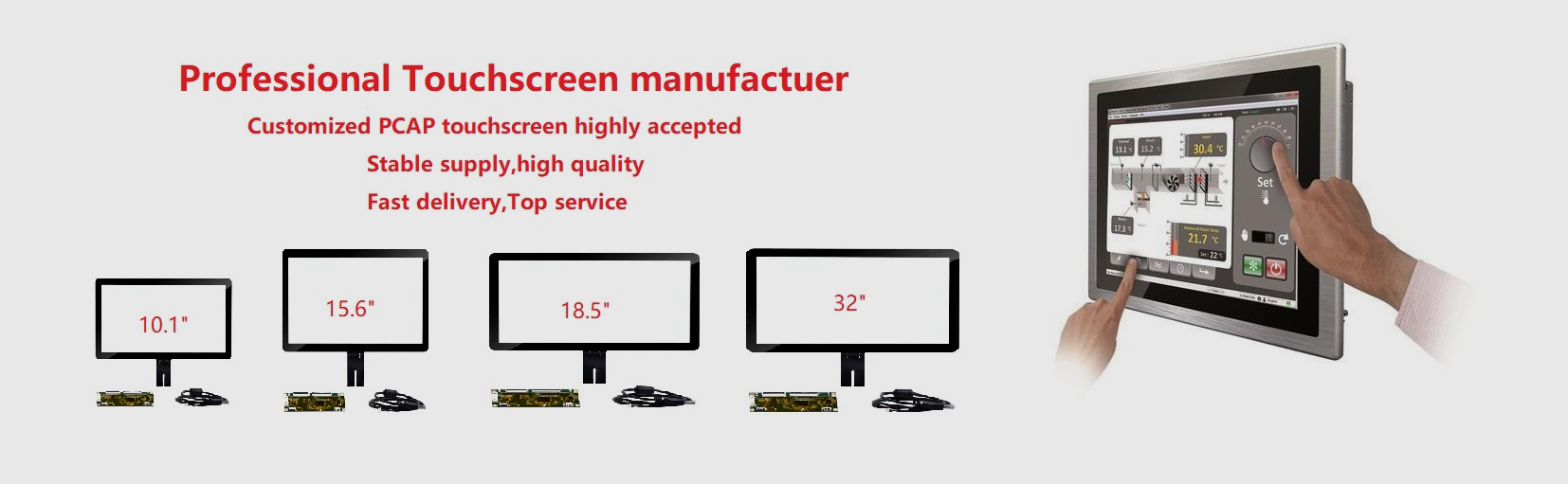

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

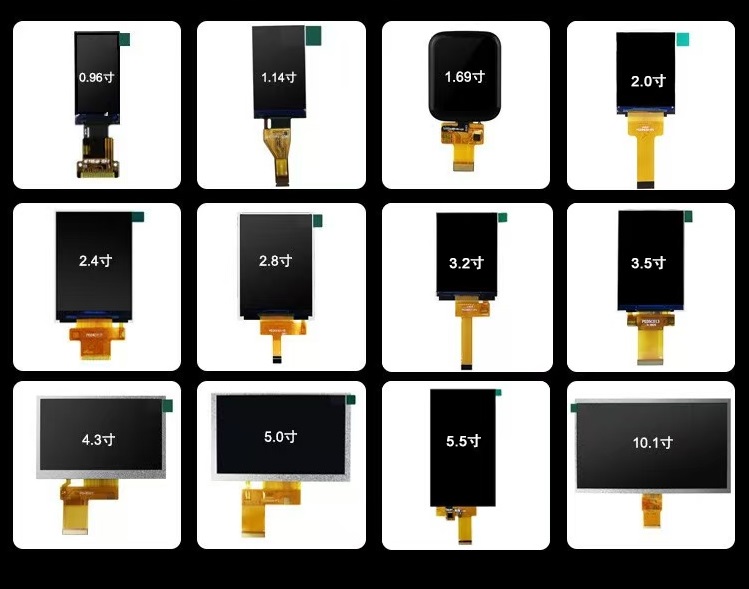

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch