News

How Is A Capacitive Touch Screen Made?

How Is A capacitive touch screen Made?

Content Menu

● 1. Overview of Capacitive Touch Screen

>> capacitive touch screen Structure

● 2. Key Components of Capacitive Touch Screen

>> 3.2 Coating with Conductive Material

>> 3.4 Etching

>> 3.5 Insulation Layer Deposition

>> 3.7 Assembly with Other Components

>> 3.8 Testing and Quality Control

● 4. Types of Capacitive Touch Screen

>> Differences Between Surface Capacitive and Projected Capacitive Screen

● 5. Advantages of Capacitive Touch Screen

● 6. Future Trends in capacitive touch screen Technology

>> Integration with IoT Devices

>> 1. What materials are used in capacitive touch screen?

>> 2. Why do capacitive touch screen not work with gloves?

>> 3. How do projected capacitive screens differ from surface capacitive screen?

>> 4. What factors affect the performance of capacitive touch screen?

>> 5. How is quality ensured during manufacturing?

Capacitive touch screen have become an integral part of our daily lives, powering the screens of our smartphones, tablets, and other touchscreen devices. Understanding how these screens are made involves exploring the intricate manufacturing processes that transform raw materials into sophisticated touch-sensitive displays. This article delves into the various stages of capacitive touch screen production, highlighting key technologies, materials, and techniques used throughout the process.

1. Overview of Capacitive Touch Screen

Capacitive touch screen operate on the principle of capacitance, utilizing the electrical properties of the human body to detect touch input. Unlike resistive touch screens, which rely on pressure, capacitive screens respond to even the lightest touches. This sensitivity is achieved through a layered structure that includes a transparent conductive material, typically Indium Tin Oxide (ITO), which forms an electrostatic field across the screen's surface.

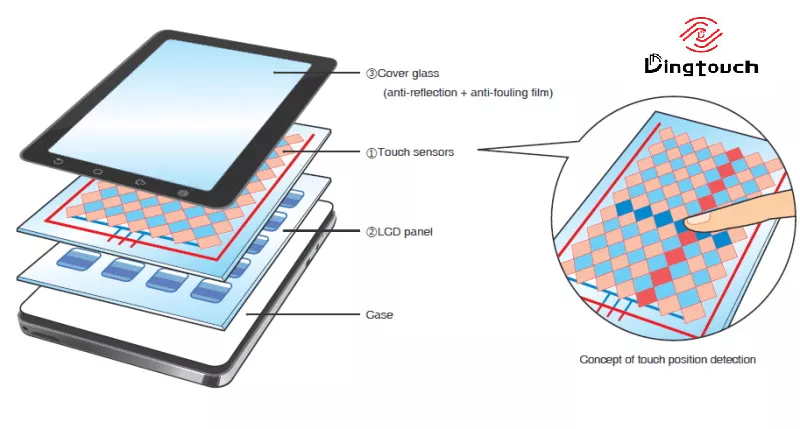

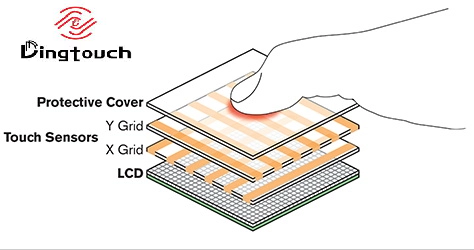

capacitive touch screen Structure

The basic structure of a capacitive touch screen consists of several layers:

- Cover Glass: The outermost layer that protects the screen and provides a smooth surface for interaction.

- Touch Sensor Layer: Contains the conductive material (ITO) that detects touch.

- Touch Control Board: Processes the signals generated by the touch sensor and communicates with the device's processor.

This multi-layered approach allows for high sensitivity and durability while maintaining excellent optical clarity.

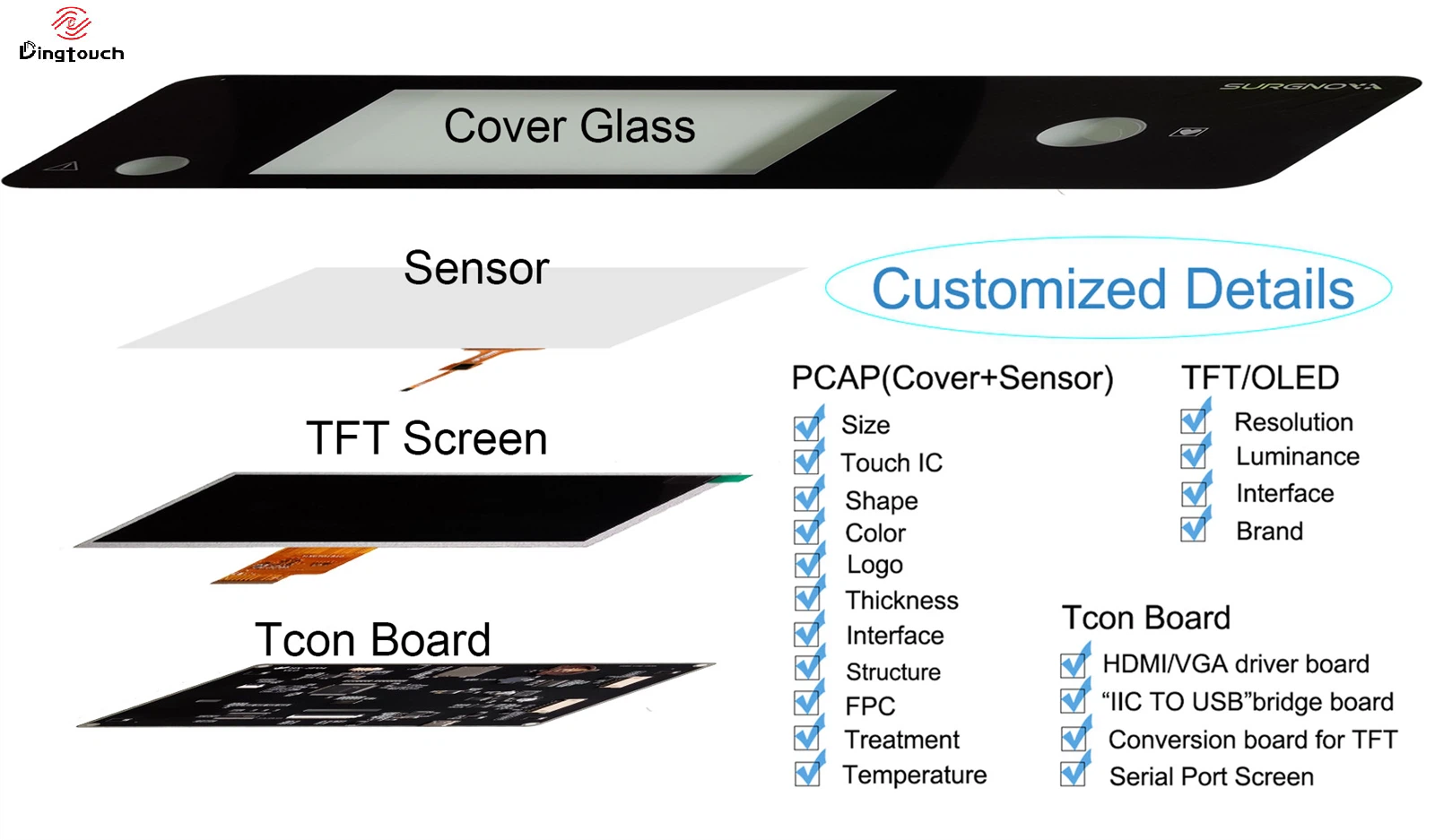

2. Key Components of Capacitive Touch Screens

The construction of a capacitive touch screen involves several essential components:

- Glass Substrate: Provides structural integrity and protection for the underlying layers.

- Conductive Layer: Usually made of ITO, this layer detects changes in capacitance when touched.

- Insulating Layer: Separates the conductive layer from the glass substrate, ensuring accurate touch detection.

- Controller: Processes touch data and translates it into actionable commands for the device.

3. Manufacturing Process

3.1 Substrate Preparation

The first step in manufacturing a capacitive touch screen is preparing the glass substrate. This involves selecting high-quality glass that meets specific criteria for transparency and durability. The glass is then cut into precise dimensions based on the specifications of the intended touchscreen device. After cutting, it undergoes a thorough cleaning process to remove any dirt, debris, or oils that might affect the quality of the touch screen.

3.2 Coating with Conductive Material

Once cleaned, a thin layer of ITO is applied to the glass substrate using one of several deposition techniques:

- Vacuum Evaporation: A method where ITO is vaporized in a vacuum chamber and deposited onto the glass.

- Sputtering: Involves bombarding a target material with ions to eject atoms that deposit onto the substrate.

- Chemical Vapor Deposition (CVD): A process where gaseous precursors react to form a solid material on the substrate.

These methods ensure that the conductive coating is uniform and adheres well to the glass surface.

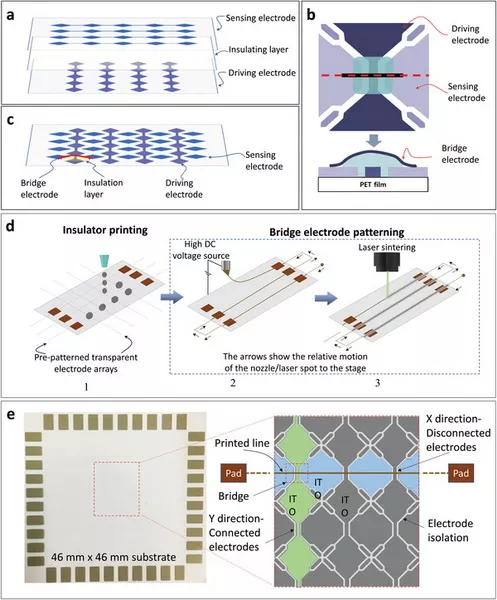

3.3 Patterning

After applying the ITO layer, photolithography is used to create patterns on the conductive surface. This involves coating the ITO with a photoresist material, exposing it to UV light through a mask, and then developing it to reveal specific patterns that will form electrodes. These patterns are crucial as they define where touch detection will occur on the screen.

3.4 Etching

The next step is etching away unwanted ITO to leave behind only the desired electrode patterns. This can be achieved through wet or dry etching processes that precisely remove material without damaging the underlying layers. The etching process is vital for ensuring that only specific areas remain conductive while others are insulated.

3.5 Insulation Layer Deposition

An insulating layer is then deposited over the patterned ITO to prevent short circuits between electrodes while allowing for effective capacitance measurement when touched. The insulation ensures that each electrode operates independently, enhancing accuracy in detecting multiple touches simultaneously.

3.6 Lamination

In this phase, multiple layers—including the glass substrate, conductive layer, and insulating layer—are laminated together using adhesives that maintain optical clarity and touch sensitivity. Vacuum lamination techniques are often employed to eliminate air bubbles and ensure uniform adhesion across all layers.

3.7 Assembly with Other Components

After lamination, additional components such as a driver IC (integrated circuit) are bonded to the touchscreen assembly using advanced techniques like Chip-On-Glass (COG) or Chip-On-Flexible (COF) methods. These processes ensure that all electronic components are securely attached and can communicate effectively with each other.

3.8 Testing and Quality Control

Quality assurance is crucial in capacitive touch screen manufacturing. Each screen undergoes rigorous testing to ensure functionality, sensitivity, and durability. Tests may include:

- Touch Sensitivity Tests: Evaluating how well the screen responds to various levels of pressure.

- Environmental Tests: Assessing performance under different temperature and humidity conditions.

- Durability Tests: Checking resistance to scratches and impacts.

These tests help manufacturers identify any defects early in production, ensuring only high-quality products reach consumers.

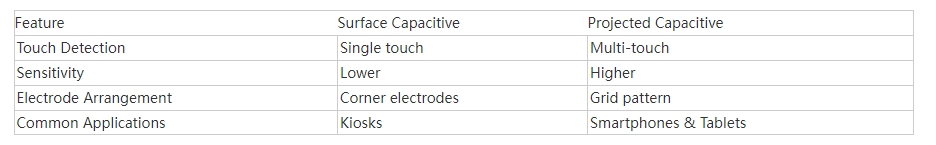

4. Types of Capacitive Touch Screens

Capacitive touch screen can be categorized into two main types:

- Surface Capacitive Touch Screens: Feature electrodes at corners that create an electric field across the surface; they can detect single touches but are less sensitive than projected capacitive screens.

- Projected Capacitive Touch Screens (PCAP): Utilize a grid of electrodes arranged in rows and columns, allowing for multi-touch capabilities and greater accuracy.

Differences Between Surface Capacitive and Projected Capacitive Screen

5. Advantages of Capacitive Touch Screens

Capacitive touch screen offer several benefits over other technologies:

- High Sensitivity: They respond quickly to light touches.

- Multi-Touch Capability: Can recognize multiple simultaneous touches for gestures like pinch-to-zoom.

- Durability: The solid glass surface resists scratches and wear.

- Clarity: Provides excellent image quality without distortion from additional layers.

6. Future Trends in Capacitive Touch Screen Technology

As technology advances, capacitive touch screen are evolving rapidly with new features and capabilities:

Flexible Touch Screens

One of the most exciting developments is flexible capacitive touch screen that can bend and curve to fit various form factors. This innovation opens up new possibilities for device design, allowing for more compact and versatile products.

Gesture Recognition

Future capacitive touch screen may incorporate advanced sensors that can detect hand movements and gestures, enabling users to control devices without physical contact. This technology could enhance accessibility and create new ways to interact with digital content.

Integration with IoT Devices

As more devices become interconnected through IoT (Internet of Things), capacitive touch screen will play a crucial role in managing and controlling these systems. Imagine a smart home where a single touchscreen interface allows you to control lighting, temperature, and security systems seamlessly.

Conclusion

The manufacturing process of capacitive touch screen is complex and requires precision at every stage—from substrate preparation to final testing. As technology continues to evolve, we can expect improvements in materials and methods that will further enhance touchscreen performance. Understanding how these screens are made not only highlights their sophistication but also informs consumers about their functionality in everyday devices.

Frequently Asked Questions

1. What materials are used in capacitive touch screen?

Capacitive touch screen primarily use glass as a substrate coated with Indium Tin Oxide (ITO) as a conductive layer. Additional materials include adhesives for lamination and protective coatings for durability.

2. Why do capacitive touch screen not work with gloves?

Standard gloves are typically made from non-conductive materials that do not allow electrical currents to pass through, preventing capacitive screen from detecting touch inputs effectively.

3. How do projected capacitive screens differ from surface capacitive screen?

Projected capacitive screen use a grid of electrodes arranged in rows and columns for multi-touch capabilities, while surface capacitive screens have electrodes at corners and typically support single-touch detection only.

4. What factors affect the performance of capacitive touch screen?

Performance can be affected by environmental conditions such as temperature and humidity, as well as by physical factors like dirt or oil on the screen surface which may interfere with touch detection.

5. How is quality ensured during manufacturing?

Quality assurance involves rigorous testing procedures including sensitivity tests, environmental tests, and durability assessments to ensure each touchscreen meets high standards before reaching consumers.

This comprehensive overview illustrates not only how capacitive touch screen are manufactured but also their significance in modern technology applications. As advancements continue in this field, we can anticipate even more innovative uses for these essential components in our daily lives.

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch