News

How Does An Lcd Screen Work?

How Does An Lcd Screen Work?

Content Menu

● 2. Basic Components of an LCD Screen

● 4. Understanding Pixel Formation in LCD Display

● 5. Advantages of LCD Technology

● 6. Limitations of LCD Technology

● 8. Applications of LCD Technology

● 9. Understanding Backlighting Process in LCD Screen

>> 1. What is the lifespan of an LCD screen?

>> 2. How do I clean my LCD screen safely?

>> 3. Why do some colors appear differently on an LCD screen?

>> 4. Can I use an LCD screen outdoors?

>> 5. What causes flickering in an LCD display?

DINGTouch:Liquid Crystal Display (LCD) technology has become ubiquitous in modern electronic devices, ranging from televisions and computer monitors to smartphones and tablets. Understanding how an LCD screen works involves delving into the intricate interplay of light, liquid crystals, and electrical signals. This article will explore the fundamental components of LCD technology, how they function together to create images, and the advantages and limitations of this display technology.

1. What is an LCD?

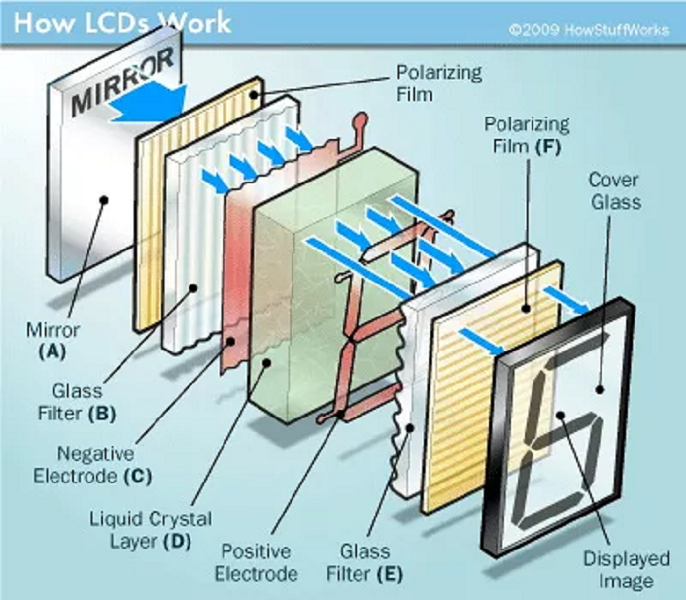

An LCD is a flat-panel display that utilizes liquid crystals to modulate light. Unlike older display technologies such as Cathode Ray Tubes (CRT), which emit light directly, LCD rely on an external light source (backlight) to illuminate the display. The liquid crystals themselves do not emit light; instead, they manipulate the light that passes through them to create images.

2. Basic Components of an LCD Screen

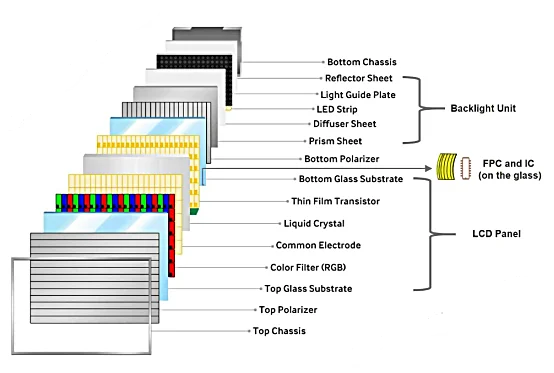

An LCD screen consists of several key components:

- Backlight: The source of illumination for the display, typically made up of LED (Light Emitting Diode) or CCFL (Cold Cathode Fluorescent Lamp) lights.

- Liquid Crystal Layer: A layer of liquid crystals sandwiched between two glass substrates. These crystals can change their orientation in response to an electric field.

- Polarizing Filters: Two polarizing filters are placed at the front and back of the liquid crystal layer. They control the direction of light passing through the liquid crystals.

- Color Filters: Each pixel is divided into three sub-pixels—red, green, and blue (RGB)—which combine to produce a full spectrum of colors.

3. How Does an LCD Work?

The operation of an LCD can be understood in several steps:

1. Backlighting: The backlight emits white light that travels towards the front of the screen.

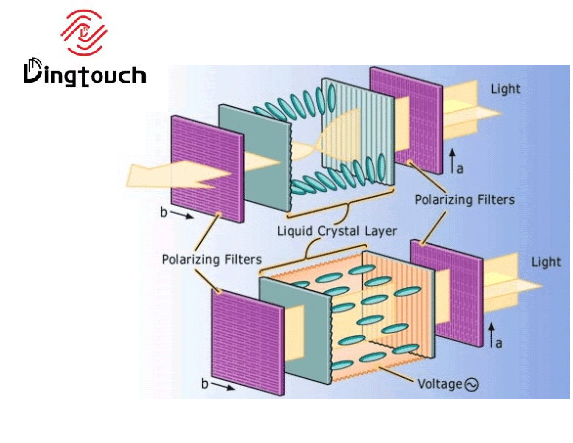

2. Polarization: The first polarizing filter allows only light waves vibrating in one direction to pass through.

3. Liquid Crystal Manipulation: When no voltage is applied to the liquid crystals, they twist the light by 90 degrees, allowing it to pass through the second polarizing filter. When voltage is applied, the liquid crystals align themselves in such a way that they do not twist the light, blocking it from passing through the second filter.

4. Color Filtering: The color filters determine which wavelengths of light can pass through each sub-pixel (red, green, or blue). By adjusting the intensity of each sub-pixel's light, a wide range of colors can be produced.

5. Image Formation: By controlling the voltage applied to each pixel's liquid crystal layer, different levels of brightness and color are achieved, creating a complete image on the screen.

4. Understanding Pixel Formation in LCD Display

Each pixel on an LCD screen consists of three sub-pixels—red, green, and blue (RGB). These sub-pixels are controlled by a matrix of thin-film transistors (TFT) that switch on and off to allow varying amounts of light to pass through.

When an electric current is applied to the liquid crystal layer, the crystals align in a way that either blocks or allows light to pass through. The degree to which the crystals twist is determined by the voltage applied, which in turn determines how much light reaches each sub-pixel. By controlling the light reaching each RGB sub-pixel, the LCD display can produce a full spectrum of colors.

5. Advantages of LCD Technology

LCD have several advantages over other display technologies:

- Energy Efficiency: LCD consume less power compared to CRT and other older technologies.

- Thin Profile: The flat-panel design allows for thinner and lighter screens.

- No Screen Burn-In: Unlike some older technologies, LCD do not suffer from burn-in effects.

- Wide Availability: LCD technology is widely used in various devices due to its versatility and cost-effectiveness.

- High Resolution: Modern LCD can support extremely high resolutions for detailed images.

6. Limitations of LCD Technology

Despite their advantages, LCD also have some limitations:

- Viewing Angles: Traditional LCD can suffer from limited viewing angles, where colors may shift or appear washed out when viewed from an angle.

- Response Time: Some types of LCD may have slower response times compared to newer technologies like OLED.

- Backlight Leakage: In some cases, uneven backlighting can lead to issues with contrast and color accuracy.

- Color Reproduction: While improving over time, some lower-quality models may struggle with accurate color reproduction compared to OLED displays.

7. Types of LCD Display

There are several types of LCD technologies based on their construction and application:

- Twisted Nematic (TN): Commonly used in budget monitors; offers fast response times but limited viewing angles.

- In-Plane Switching (IPS): Provides better color reproduction and wider viewing angles compared to TN panels but may be more expensive.

- Vertical Alignment (VA): Offers better contrast ratios than TN but typically has slower response times than IPS panels.

8. Applications of LCD Technology

LCD technology is prevalent across various applications:

- Televisions: Most modern TVs utilize LED-backlit LCD technology for high-definition displays.

- Computer Monitors: Widely used in both desktop and laptop computers for their clarity and energy efficiency.

- Mobile Devices: Smartphones and tablets often feature high-resolution LCD screens for vibrant displays.

- Digital Signage: Used in advertising displays and informational kiosks due to their visibility and clarity in various lighting conditions.

- Medical Equipment: Employed in diagnostic devices like ultrasound machines due to their precise image quality.

- Automotive Displays: Used in vehicle dashboards for displaying speed, navigation information, and infotainment controls.

9. Understanding Backlighting Process in LCD Screen

One crucial component of an LCD screen is its backlighting process. This process illuminates pixels on the screen, making images visible to viewers.

The backlighting process begins when light from a series of fluorescent or LED lamps is diffused across the screen by a diffuser panel. This diffused light then passes through polarizing filters and a liquid crystal layer that manipulates it to create images we see on-screen.

Key steps include:

1. Generation of Light

2. Diffusion

3. Manipulation by Liquid Crystals

4. Final Polarization

Each step ensures that displayed images are clear, bright, and accurately colored.

Conclusion

Understanding how an LCD screen works reveals the fascinating interplay between light, liquid crystals, and electrical signals that create vivid images on our devices. While they have certain limitations compared to newer technologies like OLED, their energy efficiency, thin profile, and versatility ensure that LCDs remain a dominant force in display technology today. As technology continues to evolve, we can expect further advancements in display quality and efficiency from this enduring technology.

Frequently Asked Questions

1. What is the lifespan of an LCD screen?

LCD screens typically have a lifespan ranging from 30,000 to 60,000 hours depending on usage conditions and backlight type.

2. How do I clean my LCD screen safely?

Use a microfiber cloth dampened with water or a specialized screen cleaner. Avoid using paper towels or harsh chemicals that can scratch or damage the screen.

3. Why do some colors appear differently on an LCD screen?

Color accuracy can be affected by factors such as viewing angle, ambient lighting conditions, and calibration settings on your device.

4. Can I use an LCD screen outdoors?

While some outdoor-rated displays exist, most standard LCD screens are not designed for direct sunlight exposure as it can affect visibility and performance.

5. What causes flickering in an LCD display?

Flickering can be caused by issues with refresh rates or electrical interference. Ensure that your device's settings are optimized for your specific monitor model.

This comprehensive exploration has expanded our understanding beyond just how an LCD operates; it includes its types, applications across various fields such as medical equipment and automotive displays as well as its advantages over other technologies while acknowledging its limitations too—all contributing factors that help users make informed decisions regarding their use in everyday life.

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch