News

How Does A Lcd Screen Work?

How Does A Lcd Screen Work?

Content Menu

● 1. The Basics of LCD Technology

● 2. Components of an LCD Screen

>> Backlight

>> Polarizers

● 5. Advantages and Disadvantages of LCD Technology

>> Advantages:

● 6. The Backlighting Process in LCD Screen

● 7. Pixel Formation in LCD Display

● 8. Innovations in LCD Technology

● 9. Applications of LCD Technology

>> 2. How does an LCD screen produce color?

>> 3. What are the main types of LCD technologies?

>> 4. Why do LCD screen require a backlight?

>> 5. What are some common applications for LCD technology?

Liquid Crystal Display (LCD) have become an integral part of our daily lives, appearing in devices such as televisions, computer monitors, smartphones, and tablets. Understanding how these screens work provides insight into the technology that powers our visual experiences. This article will explore the inner workings of LCD technology, detailing its components, operation principles, and applications.

1. The Basics of LCD Technology

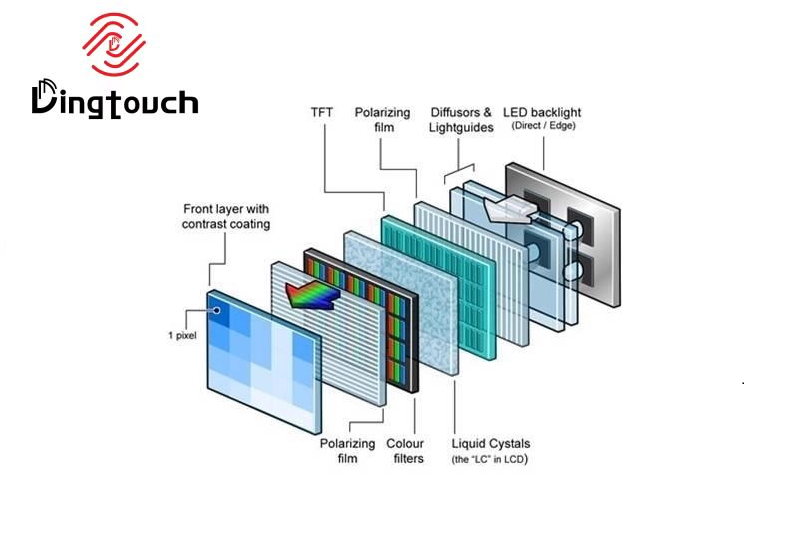

LCDs are flat-panel displays that utilize the light-modulating properties of liquid crystals combined with polarizers to create images. Unlike traditional cathode-ray tube (CRT) displays, which emit light directly, LCDs manipulate existing light to form images. The fundamental components of an LCD include:

- Backlight: Provides the necessary illumination for the display.

- Liquid Crystal Layer: Controls the passage of light based on electrical signals.

- Polarizers: Filter light to enhance contrast and color accuracy.

- Color Filters: Separate light into red, green, and blue components to produce a full spectrum of colors.

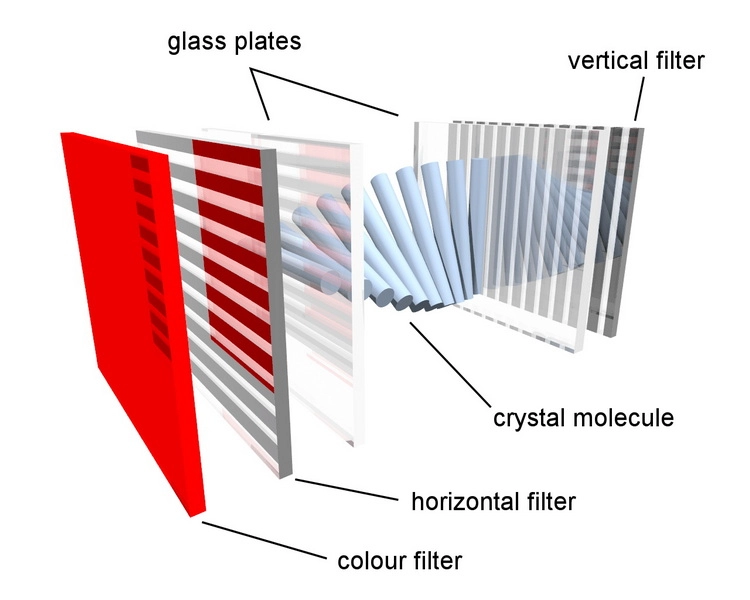

2. Components of an LCD Screen

An LCD screen consists of several layers that work together to display images:

Backlight

The backlight is crucial for illuminating the screen since liquid crystals do not emit light on their own. Most modern LCDs use LED (Light Emitting Diode) backlighting due to its energy efficiency and ability to produce vibrant colors. The backlight can be either edge-lit or direct-lit, with edge-lit being thinner and more common in portable devices.

Liquid Crystal Layer

The heart of an LCD is the liquid crystal layer, which is sandwiched between two glass substrates. Liquid crystals are unique materials that can change their orientation when an electric field is applied. This property allows them to control how much light passes through.

Polarizers

Two polarizing filters are placed at the front and back of the liquid crystal layer. The first polarizer allows light waves vibrating in a specific direction to pass through, while the second polarizer blocks all other orientations of light. This setup is essential for controlling the visibility of images on the screen.

Color Filters

Each pixel on an LCD is divided into three sub-pixels—red, green, and blue (RGB). Color filters placed over these sub-pixels allow only specific wavelengths of light to pass through, enabling the display to produce a wide range of colors.

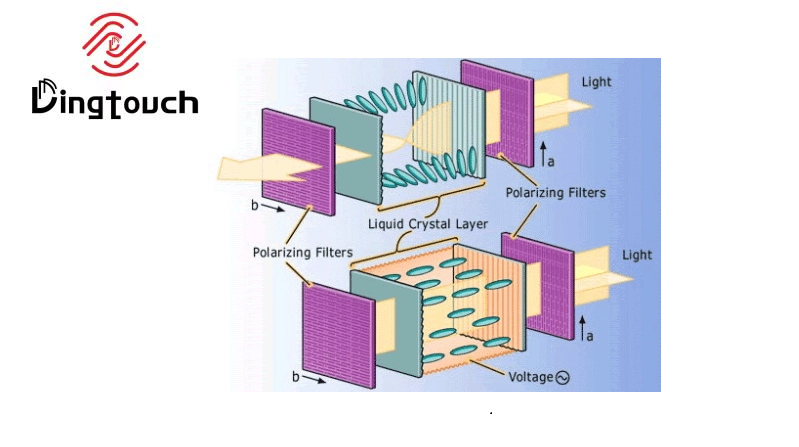

3. How LCD Screens Work

The operation of an LCD screen can be broken down into several steps:

1. Backlight Activation: The backlight emits white light that passes through the first polarizer.

2. Polarization: The first polarizer filters the light, allowing only waves vibrating in one direction to pass through.

3. Liquid Crystal Manipulation: When no voltage is applied to the liquid crystals, they remain twisted at 90 degrees, allowing polarized light to pass through and reach the second polarizer. If voltage is applied, the liquid crystals untwist and block the light from passing through.

4. Color Production: Each pixel's sub-pixels (RGB) can be activated independently by controlling the voltage applied to them. By adjusting the intensity of each sub-pixel, various colors can be produced.

5. Image Formation: The combination of all pixels creates a complete image on the screen.

4. Types of LCD Technology

There are several types of LCD technologies that differ in how they control pixels and produce images:

Twisted Nematic (TN)

This is one of the oldest and most common types of LCD technology. TN panels offer fast response times but have limited viewing angles and color reproduction capabilities.

In-Plane Switching (IPS)

IPS technology improves upon TN by providing wider viewing angles and better color accuracy. It achieves this by aligning liquid crystals horizontally rather than twisting them.

Vertical Alignment (VA)

VA panels offer high contrast ratios and deep blacks but may have slower response times compared to TN and IPS panels.

5. Advantages and Disadvantages of LCD Technology

Advantages:

- Energy Efficiency: Compared to CRT monitors, LCDs consume less power.

- Thin Profile: Their flat design allows for space-saving applications.

- Less Eye Strain: The flicker-free display reduces eye fatigue during prolonged use.

Disadvantages:

- Limited Viewing Angles: Some types suffer from color distortion when viewed from angles other than straight on.

- Response Time: Some models may have slower response times, leading to motion blur in fast-moving images.

6. The Backlighting Process in LCD Screen

One of the most crucial components of an LCD screen is the backlighting process. This process is responsible for illuminating the pixels on the screen, making images visible to viewers. The backlighting process begins when light from a series of fluorescent or LED lamps is diffused across the screen by a panel known as a diffuser.

This diffused light then passes through a series of polarizing filters and a liquid crystal layer, which manipulates the light to create images we see. Key steps in this process include:

- Generation of Light: The backlight generates white light.

- Diffusion of Light: Diffusers spread out this light evenly across the display surface.

- Manipulation by Liquid Crystals: The liquid crystal layer adjusts how much light passes through based on electrical signals.

- Final Polarization: The second polarizer finalizes what reaches our eyes based on how much light has been allowed through by the liquid crystals.

7. Pixel Formation in LCD Display

Pixel formation in LCD display involves a complex interplay between light, color, and electricity:

- Each pixel on an LCD screen consists of three sub-pixels: red, green, and blue.

- These sub-pixels are controlled by a matrix of thin-film transistors (TFTs) that switch on and off to allow varying amounts of light to pass through.

When an electric current is applied to the liquid crystal layer, it changes orientation based on voltage levels:

- Low voltage allows more light through (bright).

- High voltage blocks more light (dark).

By controlling each sub-pixel's intensity independently, a full spectrum of colors can be produced across the display.

8. Innovations in LCD Technology

Recent advancements in LCD technology include:

Quantum Dot Technology

Quantum dots enhance color accuracy and brightness by utilizing tiny semiconductor particles that emit specific wavelengths when illuminated by a backlight.

Mini-LED Backlighting

This method employs thousands of tiny LEDs for better control over brightness levels across different areas of the screen, resulting in deeper blacks and brighter whites.

High Dynamic Range (HDR)

HDR technology improves contrast ratios significantly by allowing displays to show more detail in both bright highlights and dark shadows.

These innovations are helping push LCD technology closer to OLED performance while maintaining cost-effectiveness.

9. Applications of LCD Technology

LCD technology has found widespread application across various fields due to its versatility:

Consumer Electronics

- Televisions

- Computer Monitors

- Smartphones

- Tablets

Digital Signage

- Advertising Display

- Menu Boards

- Information Kiosks

Automotive Display

- Dashboard Screens

- Infotainment Systems

Medical Equipment

- Diagnostic Devices

- Patient Monitors

Conclusion

LCD technology has revolutionized how we interact with visual media by providing thin, energy-efficient displays with high-quality images. Understanding its inner workings—from liquid crystal manipulation to backlighting—helps us appreciate this essential technology that has become ubiquitous in modern life.

Frequently Asked Questions

1. What is an LCD screen?

An LCD screen is a type of flat-panel display that uses liquid crystal technology combined with polarizers to manipulate light and create images.

2. How does an LCD screen produce color?

Colors are produced by combining different intensities of red, green, and blue light emitted from sub-pixels within each pixel on the screen.

3. What are the main types of LCD technologies?

The main types include Twisted Nematic (TN), In-Plane Switching (IPS), and Vertical Alignment (VA), each with distinct advantages and disadvantages regarding color accuracy and viewing angles.

4. Why do LCD screen require a backlight?

LCD screens do not emit their own light; they rely on a backlight to illuminate the liquid crystal layer so that images can be seen clearly.

5. What are some common applications for LCD technology?

LCD technology is widely used in televisions, computer monitors, smartphones, tablets, digital signage, automotive display, medical equipment, and various portable devices like cameras and watches.

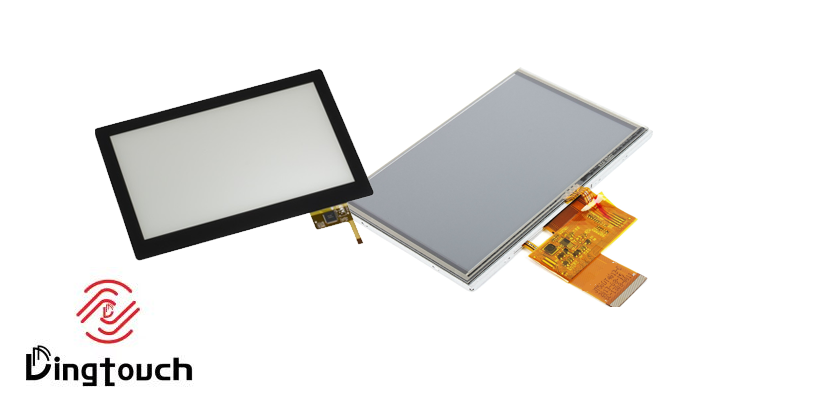

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

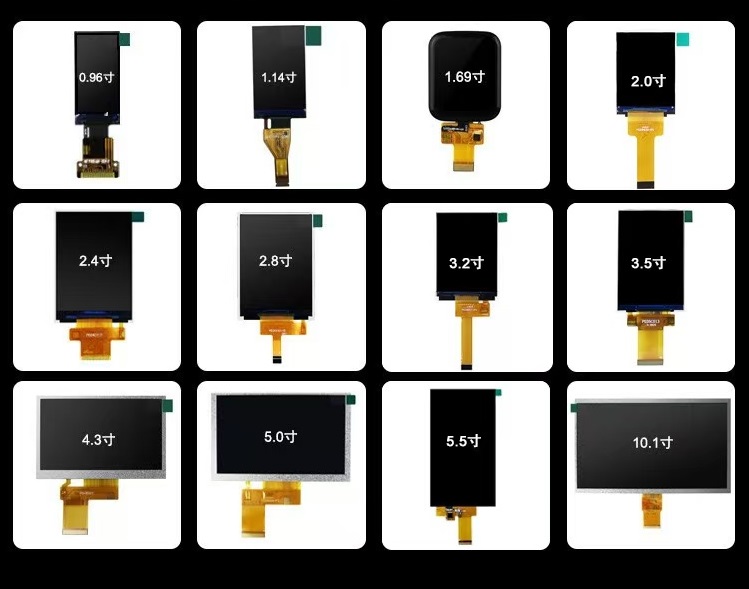

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch