News

Does Resistive Tips Work on Touch Screen?

Does Resistive Tips Work on Touch Screen?

Content Menu

● Understanding Resistive Touch Screen

● Advantages of Resistive Touch Screen

● Disadvantages of Resistive Touch Screen

● Applications of Resistive Touch Screen

● Do Resistive Tips Work on Touch Screen?

● The Evolution of Resistive Touch Screen Technology

● Future Trends in Resistive Touch Screen Technology

● Additional Insights into Resistive Touch Screen Technology

>> 1. What is the main difference between resistive and capacitive touch screen?

>> 2. Can I use a stylus with a resistive touch screen?

>> 3. Are resistive touch screen more durable than capacitive ones?

>> 4. How long do resistive touch screen last?

>> 5. Do resistive touch screen support multi-touch?

Touch screen have become an integral part of modern technology, facilitating user interaction across various devices such as smartphones, tablets, and industrial equipment. Among the different types of touch screens available, resistive touch screen are notable for their unique working mechanism. This article explores whether resistive tips work on touch screens, the technology behind resistive screens, their advantages and disadvantages, and practical applications.

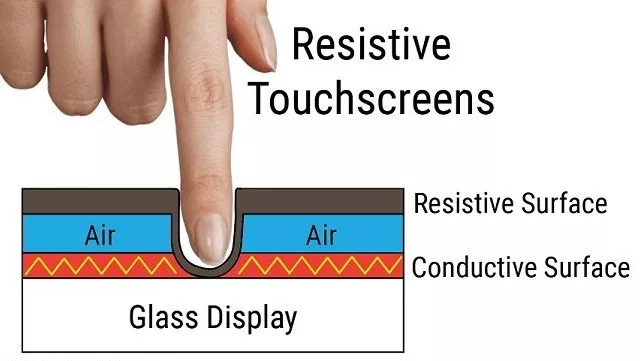

Understanding Resistive Touch Screen

A resistive touch screen operates by detecting pressure applied to its surface. Unlike capacitive touch screens, which rely on the electrical properties of the human body, resistive screens consist of multiple layers that respond to physical pressure.

How Resistive Touch Screen Work:

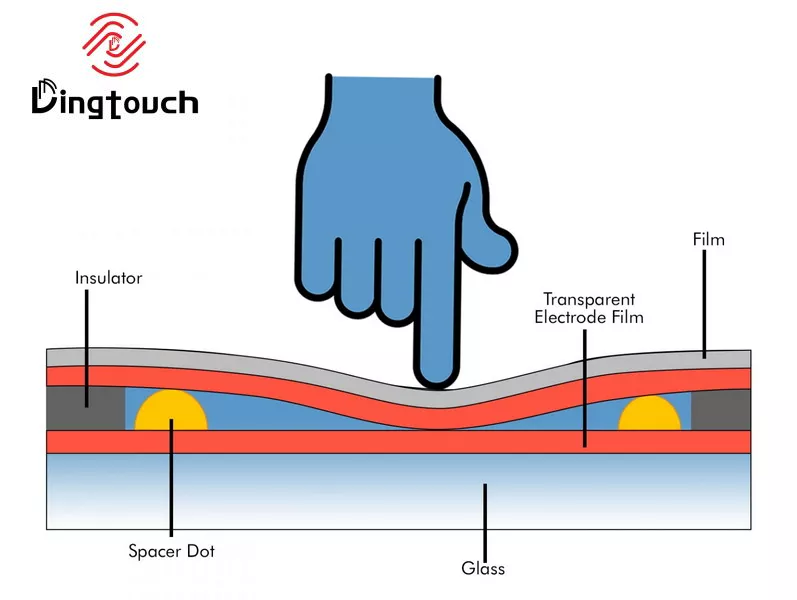

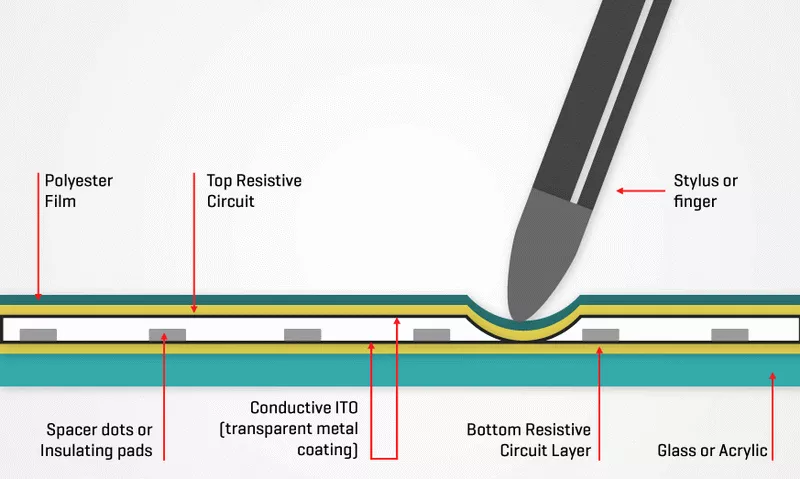

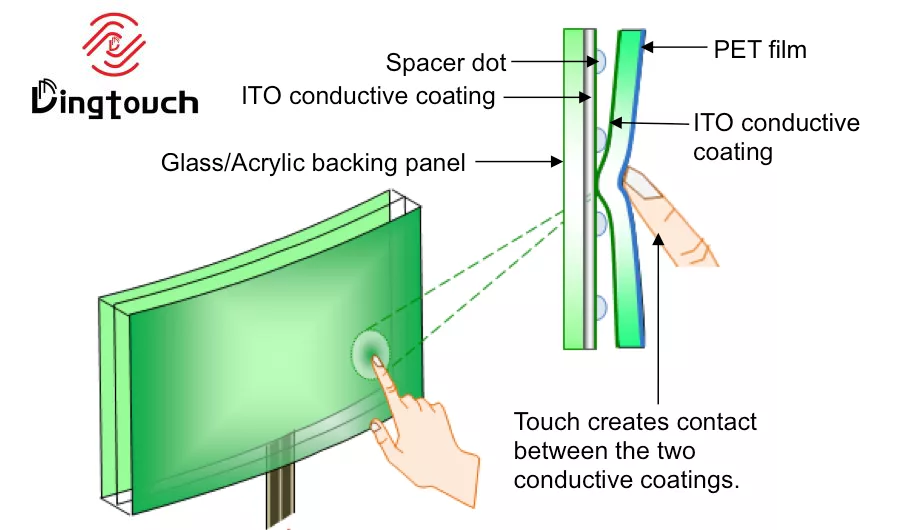

1. Layer Structure: A typical resistive touch screen comprises two flexible layers coated with a conductive material. These layers are separated by a small gap maintained by tiny spacer dots.

2. Pressure Detection: When a user presses down on the top layer, it bends and makes contact with the bottom layer. This contact creates a change in electrical resistance, which is interpreted by the device as a touch input.

3. Touch Coordinates: The specific point of contact is detected through voltage changes across the layers, allowing the system to register the precise location of the touch.

Resistive Touch Screen Mechanism

Advantages of Resistive Touch Screen

Resistive touch screen offer several benefits that make them suitable for various applications:

- Versatility in Input: They can be operated using any object that applies pressure, including fingers (even when gloved), styluses, or other pointed objects.

- Cost-Effectiveness: Generally less expensive to manufacture than capacitive screens, making them ideal for budget-sensitive projects.

- Durability Against Contaminants: More resistant to dust and moisture than capacitive screen, making them suitable for harsh environments like factories and hospitals.

- High Accuracy: They can provide accurate input detection, especially when using a stylus for drawing or writing.

Disadvantages of Resistive Touch Screen

While resistive touch screen have clear advantages, they also come with limitations:

- Pressure Requirement: They require more pressure to register a touch compared to capacitive screens. This can lead to user fatigue during prolonged use.

- Limited Multi-Touch Capability: Traditional resistive screen typically support only single-touch input. Some advanced versions may allow dual-touch but are not as responsive as capacitive screens.

- Lower Sensitivity: The need for pressure means they are less sensitive than capacitive counterparts, which can affect user experience.

- Reduced Display Clarity: The additional layers in resistive screens can cause lower light transmission rates, affecting visibility under certain lighting conditions.

Applications of Resistive Touch Screen

Resistive touch screen are widely used in various industries due to their unique advantages:

- Industrial Equipment: Commonly found in machinery control panels where durability and resistance to contaminants are essential.

- Medical Devices: Often used in devices that require precise input while being operable with gloves.

- Point-of-Sale Terminals: Frequently utilized in retail environments where users may need to interact with the screen using styluses or other non-finger inputs.

- Consumer Electronics: Found in some handheld devices like GPS units or older mobile phones where cost is a significant factor.

Do Resistive Tips Work on Touch Screen?

Yes, resistive tips do work on resistive touch screen. Since these screens detect input based on pressure rather than electrical conductivity, any object that can apply sufficient pressure—including styluses designed for resistive screens—will function effectively. This capability allows for more precise control when drawing or writing on devices equipped with resistive technology.

The Evolution of Resistive Touch Screen Technology

Resistive touchscreen technology has evolved significantly since its inception in the 1960s. Originally developed as a cost-effective alternative to other touchscreen technologies, it has undergone numerous improvements over the decades. Modern resistive touchscreens now feature enhanced durability and sensitivity due to advancements in materials and manufacturing processes.

Historical Context

The first patents for touchscreen technology were filed in the early 1980s, leading to widespread adoption in industrial settings. Over time, as consumer electronics became more prevalent, resistive touchscreens found their way into devices like PDAs and early mobile phones. Their affordability made them an attractive option for manufacturers looking to incorporate touch interfaces into their products.

Future Trends in Resistive Touch Screen Technology

As technology continues to advance, resistive touchscreens are expected to see further innovations aimed at enhancing their functionality and performance. Potential developments include:

- Multi-Touch Capabilities: While traditional resistive screens support only single-touch inputs, advancements may allow for multi-touch functionalities similar to those found in capacitive systems.

- Improved Sensitivity and Accuracy: Future designs may incorporate better materials and sensor technologies that enhance responsiveness and accuracy without compromising durability.

- Integration with Flexible Displays: As flexible display technologies emerge, integrating them with resistive touchscreen capabilities could open new avenues for product design and application.

Additional Insights into Resistive Touch Screen Technology

To further understand the significance of resistive touchscreen technology in today's world:

- User Experience Considerations: While many users prefer the responsiveness of capacitive touchscreens for everyday tasks like scrolling or zooming, there are scenarios where the tactile feedback provided by a resistive screen is advantageous—especially when precision is required or when using tools like styluses or pens for drawing or writing applications.

- Environmental Adaptability: The ability of resistive touchscreens to function effectively under extreme conditions—such as high humidity or exposure to dust—makes them particularly valuable in industrial settings where other types might fail due to environmental stressors.

- Cost Implications: For businesses looking at budget constraints while maintaining functionality, choosing resistive technology can lead to significant savings without compromising usability for specific applications like kiosks or control panels in manufacturing settings.

In summary, while both types of touchscreen technologies have their respective strengths and weaknesses, understanding the specific needs of an application will guide users toward selecting the most appropriate technology—whether that be a responsive capacitive screen or a versatile and durable resistive one.

Conclusion

In conclusion, resistive touch screen remain relevant in various applications due to their unique advantages such as versatility in input methods and durability against environmental factors. While they may not match the sensitivity and multi-touch capabilities of capacitive touch screens, they offer reliable performance in situations where precise input is necessary. Understanding how these screens work and their strengths can help users make informed decisions about their use in different contexts.

Frequently Asked Questions

1. What is the main difference between resistive and capacitive touch screen?

Resistive touch screen detect input through pressure applied to the screen surface, while capacitive touch screens rely on changes in electrical fields created by the human body.

2. Can I use a stylus with a resistive touch screen?

Yes! Resistive touch screen can be used with any pointed object or stylus that applies sufficient pressure to register a touch.

3. Are resistive touch screen more durable than capacitive ones?

Yes! They are generally more resistant to dust and moisture, making them suitable for harsher environments compared to capacitive touch screen.

4. How long do resistive touch screen last?

High-quality resistive touchscreen devices can endure over 200,000 touches before showing significant wear.

5. Do resistive touch screen support multi-touch?

Traditional resistive touchscreen models typically support only single-touch input; however, some modern variants may allow dual-touch functionality depending on design specifications.

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

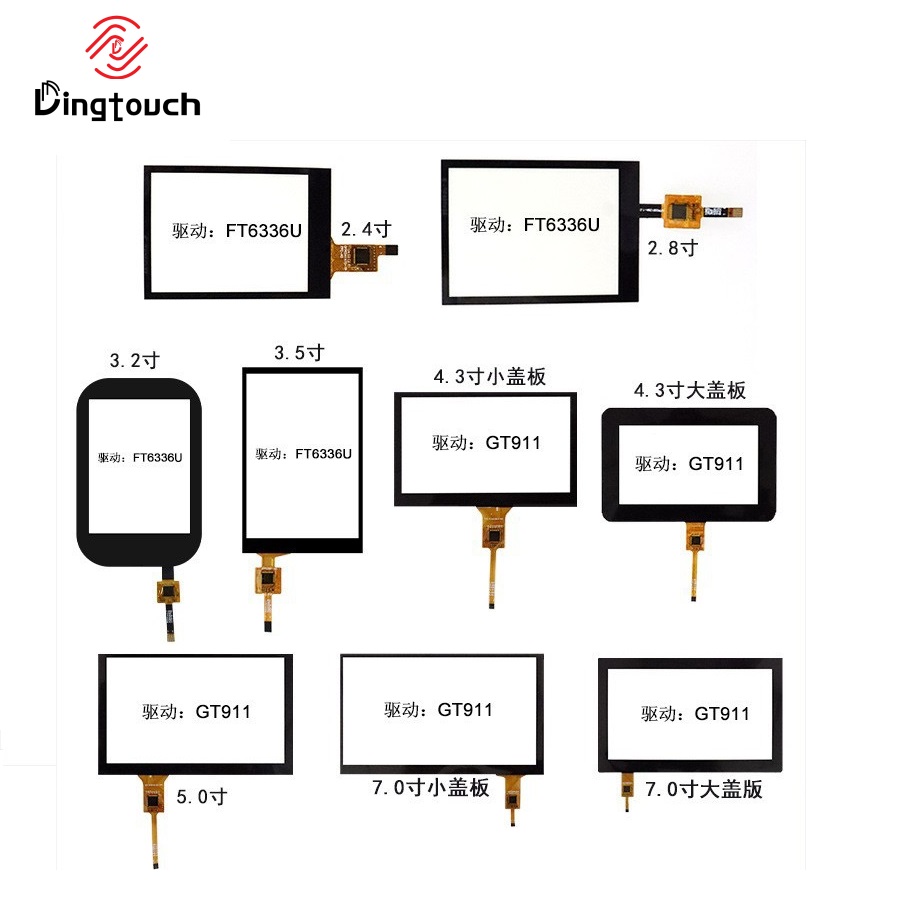

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch