News

Can You Trim Resistive Touch Screen?

Can You Trim Resistive Touch Screen?

Content Menu

● What is a Resistive Touch Screen?

>> Advantages of Resistive Touch Screen

>> Disadvantages of Resistive Touch Screen

● Can You Trim a Resistive Touch Screen?

>> Steps to Trim a Resistive Touch Screen

● Understanding Resistive Touch Screen Technology

● Future Trends in Touch Screen Technology

>> Innovations in Resistive Technology

>> 1. What Are the Main Differences Between Resistive and Capacitive Touch Screen?

>> 2. Can I Replace a Resistive Touch Screen?

>> 3. How Do I Calibrate My Resistive Touch Screen After Trimming?

>> 4. Are There Any Safety Precautions When Trimming a Touch Screen?

>> 5. What Should I Do If My Trimming Damaged My Touch Screen?

Introduction

Resistive touch screen are a common technology used in various devices, including smartphones, tablets, and industrial equipment. Unlike capacitive touch screens, which rely on the electrical properties of the human body, resistive screens detect pressure applied to the surface. This fundamental difference allows for unique applications but raises questions about their adaptability, particularly regarding modification or trimming. This article explores whether you can trim a resistive touch screen and the implications of doing so.

What is a Resistive Touch Screen?

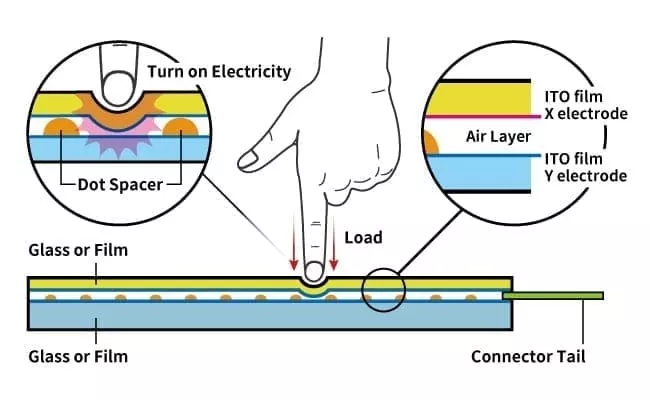

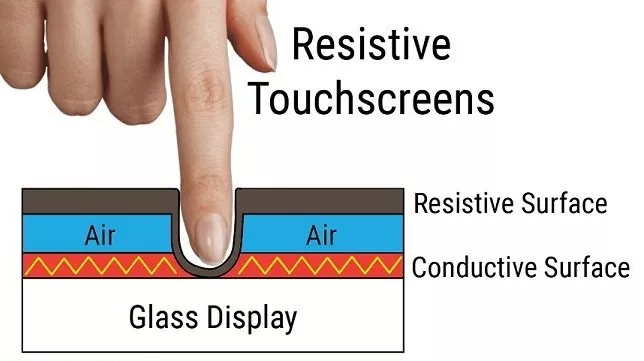

A resistive touch screen consists of multiple layers, primarily two thin layers of conductive material separated by a small gap. When pressure is applied to the outer layer, it makes contact with the inner layer, registering a touch event. This technology is widely used due to its durability and ability to work with various input methods, including fingers, styluses, and gloves.

Advantages of Resistive Touch Screen

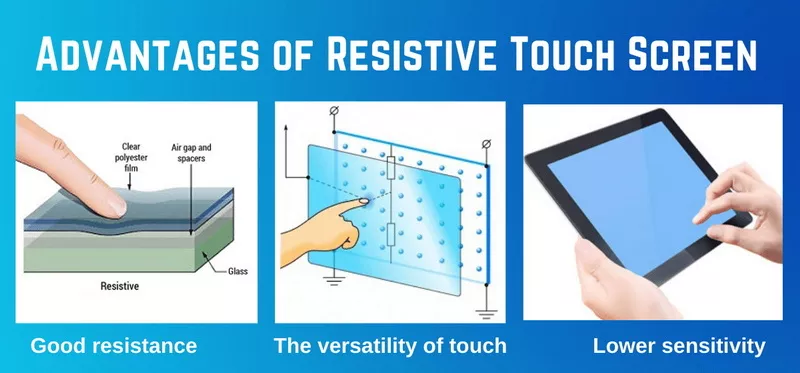

- Cost-Effective: Generally cheaper to produce than capacitive screen.

- Versatile Input: Can be operated with any object, making them suitable for various environments.

- Durable: Resistant to dust and water, making them ideal for industrial applications.

Disadvantages of Resistive Touch Screen

- Lower Sensitivity: Requires more pressure to register a touch compared to capacitive screens.

- Limited Multi-Touch Capability: Typically supports only one touch point at a time.

Can You Trim a Resistive Touch Screen?

The short answer is yes; you can trim a resistive touch screen. However, doing so comes with significant risks and potential drawbacks. Trimming involves cutting down the physical size of the screen to fit a specific application or device. Here are some considerations:

Risks Involved in Trimming

- Damage to Layers: Cutting through the layers can damage the conductive materials, rendering the screen inoperable.

- Loss of Functionality: Trimming may affect the sensitivity and accuracy of touch detection.

- Warranty Void: Most manufacturers will void warranties if modifications are made.

Steps to Trim a Resistive Touch Screen

If you decide to proceed with trimming a resistive touch screen, follow these steps cautiously:

1. Gather Tools: You'll need a sharp utility knife or scissors, a ruler for precise measurements, and protective eyewear.

2. Measure Carefully: Before cutting, measure the desired dimensions multiple times to avoid mistakes.

3. Cut Slowly: Use steady pressure and cut along straight lines to minimize damage.

4. Test Functionality: After trimming, connect the screen to its device and test for functionality before final installation.

Implications of Trimming

Trimming a resistive touch screen can lead to several implications that should be considered:

Performance Issues

Trimming may lead to performance issues such as:

- Reduced Sensitivity: The area around the edges may not register touches effectively.

- Calibration Problems: The screen may require recalibration after trimming to ensure accurate touch response.

Aesthetic Concerns

Modifying the size of a touch screen can also affect its appearance:

- Rough Edges: Cutting can leave jagged edges that may not look professional or appealing.

- Incompatibility with Housing: The modified screen may not fit well within its housing or bezel.

Alternatives to Trimming

If trimming seems too risky or impractical, consider these alternatives:

- Use Smaller Devices: Instead of modifying an existing screen, consider purchasing a device that already meets your size requirements.

- Custom Manufacturing: Some companies specialize in creating custom-sized resistive touch screens tailored to specific applications.

Understanding Resistive Touch Screen Technology

To appreciate the implications of trimming a resistive touch screen fully, it's essential to understand how this technology works. Resistive touch screens are constructed from two flexible layers coated with conductive materials such as indium tin oxide (ITO). These layers are separated by tiny spacer dots that create an air gap. When pressure is applied—like when you tap on it—the two layers make contact at that point. This contact changes the electrical resistance between the layers, allowing the device's controller to determine where the touch occurred based on voltage changes.

This design gives resistive screen several advantages over capacitive ones:

- They can be used in various environments since they are less affected by external conditions like moisture or dirt.

- They allow for interaction using any object—be it a finger, stylus, or even gloved hands—making them ideal for industrial applications where users might wear protective gear.

However, this technology also has limitations:

- The single-point detection means that gestures like pinch-to-zoom cannot be performed effectively on standard resistive screens.

- Over time, repeated pressure can lead to wear and tear on the top layer, which may reduce clarity and responsiveness.

Durability Considerations

One of the primary reasons resistive touch screens are favored in certain applications is their durability. The outer layer is often made from materials like PET (polyethylene terephthalate), which can withstand significant wear. However, this does not mean they are impervious to damage.

Common Causes of Damage

- Scratches and Abrasions: The top layer can easily scratch if sharp objects come into contact with it frequently.

- Impact Damage: Dropping or hitting the device can lead to cracks or complete breakage of the screen.

- Environmental Factors: While they are generally resistant to moisture and dust, prolonged exposure to harsh chemicals can degrade their performance over time.

Maintenance Tips

To prolong the life of a resistive touch screen:

- Use protective films or covers designed specifically for your device.

- Clean regularly using soft cloths and appropriate cleaning solutions that do not contain harsh chemicals.

- Avoid using sharp objects directly on the screen surface; instead, opt for styluses designed for resistive screens when needed.

Future Trends in Touch Screen Technology

As technology evolves, so do user expectations regarding interface responsiveness and functionality. While resistive touch screens have their place in various applications today, advancements in capacitive technology continue to dominate consumer markets due to their superior sensitivity and multi-touch capabilities.

Innovations in Resistive Technology

Despite being overshadowed by capacitive screens in many consumer applications, innovations continue within resistive technology:

- Multi-Touch Capabilities: Newer designs are emerging that allow for limited multi-touch capabilities while maintaining resistive functionality.

- Enhanced Durability Options: Manufacturers are developing more robust materials that withstand scratches and impacts better than traditional PET layers.

Conclusion

While it is technically possible to trim a resistive touch screen, it carries significant risks that could lead to damage or reduced functionality. It is essential to weigh these risks against your needs before proceeding. If you choose not to trim your device's touch screen, there are alternatives available that might better suit your requirements without compromising performance or aesthetics.

Resistive technology remains valuable in specific contexts where durability and versatility outweigh other concerns like sensitivity and multi-touch capability. As advancements continue in both resistive and capacitive technologies, users will have more options tailored precisely for their needs.

Related Questions

1. What Are the Main Differences Between Resistive and Capacitive Touch Screen?

Resistive screen detect pressure applied directly on their surface while capacitive screen use electrical properties of the human body for detection. Capacitive screens are generally more sensitive and support multi-touch gestures better than resistive screens.

2. Can I Replace a Resistive Touch Screen?

Yes, replacing a resistive touch screen is possible but requires careful disassembly of the device and proper handling of components. It's advisable to consult professional services for replacement tasks.

3. How Do I Calibrate My Resistive Touch Screen After Trimming?

Calibration usually involves accessing settings on your device where you can adjust sensitivity and alignment settings according to your needs after trimming.

4. Are There Any Safety Precautions When Trimming a Touch Screen?

Always wear protective eyewear when cutting materials and work in a well-lit area. Ensure that any electronic components are powered off before starting work on them.

5. What Should I Do If My Trimming Damaged My Touch Screen?

If damage occurs during trimming, consult with a professional repair service or consider replacing the entire unit if repairs are not feasible.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch