News

Can You Repair An Lcd Screen?

Can You Repair An Lcd Screen?

Content Menu

● Understanding LCD Technology

>> Dead Pixels

>> Tools Needed

● Step-by-Step Guide for Cracked Screen

>> Dealing with Flickering Screen

● Professional Repair Services

>> Benefits of Professional Repair

● Additional Repair Techniques

>> Toothpaste for Minor Scratches

● Exploring Further Repair Techniques

● Advanced Techniques for Persistent Issues

● Managing Color Distortion Problems

>> Inspect Internal Connections

● Final Thoughts on Repairing Your LCD Screen

>> 1. How much does it cost to repair an LCD screen?

>> 2. Can I replace just the glass on my LCD screen?

>> 3. What tools do I need for an LCD repair?

>> 4. How long does it take to repair an LCD screen?

>> 5. Are there any risks involved in DIY repairs?

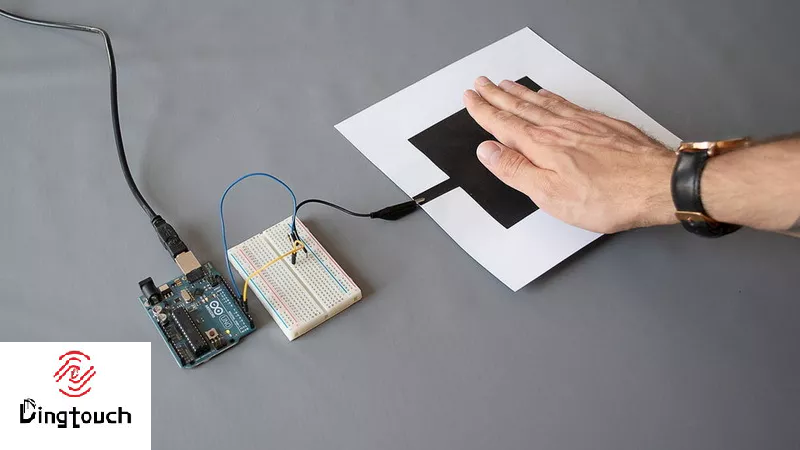

DINGTouch:LCD (Liquid Crystal Display) screen are prevalent in various devices, including televisions, computer monitors, smartphones, and tablets. While these screens offer excellent picture quality and energy efficiency, they are also susceptible to damage. This article explores the possibility of repairing an LCD screen, the common types of damage, and the steps involved in the repair process.

Understanding LCD Technology

Before delving into repairs, it's essential to understand how LCD technology works. An LCD screen consists of several layers:

- Backlight: Provides illumination.

- Liquid crystals: Control light passage to create images.

- Polarizers: Filter light to enhance visibility.

- Glass substrate: Protects the internal components.

This complex structure makes LCD screen delicate and prone to various types of damage.

Common Types of Damage

LCD screen can suffer from several issues, including:

- Cracked Screens: Physical impact can lead to cracks.

- Dead Pixels: Pixels that do not display any color.

- Discoloration: Areas of the screen may show incorrect colors.

- Flickering or Distortion: Issues with the display refresh rate or connections.

Cracked Screen

Cracks are one of the most common problems with LCD screen. They can result from drops, pressure, or manufacturing defects. Depending on the severity, a cracked screen may still function but can lead to further damage if not addressed.

Dead Pixels

Dead pixels appear as small black or white dots on the screen. They occur when liquid crystals fail to respond correctly. While some dead pixels can be fixed using software solutions, others may require physical repairs.

Discoloration

Discoloration can manifest as patches of incorrect colors or overall fading. This issue often arises from damage to the polarizing filters or liquid crystal layers.

Flickering or Distortion

Flickering screen can be caused by faulty connections or issues with the backlight. This problem is often temporary but can indicate underlying hardware issues.

Assessing Damage

Before attempting repairs, assess the extent of the damage. Here's how to evaluate your LCD screen:

1. Visual Inspection: Look for cracks, discoloration, and dead pixels.

2. Functionality Test: Check if the display responds to touch (for touchscreens) and if all areas show images correctly.

3. External Connections: Ensure that cables and connectors are secure.

DIY Repair Options

Repairing an LCD screen can be a challenging task. However, for those willing to try, here are some DIY options:

Tools Needed

- Screwdriver set

- Plastic spudger

- Tweezers

- Replacement parts (if necessary)

- Cleaning cloth

- Isopropyl alcohol

Step-by-Step Guide for Cracked Screen

1. Power Off Device: Always turn off and unplug your device before starting any repairs.

2. Remove Back Cover: Use a screwdriver to remove screws holding the back cover in place. Carefully use a plastic spudger to pry it open without damaging internal components.

3. Disconnect Battery: If applicable, disconnect the battery to prevent any electrical shorts.

4. Remove Damaged Screen:

- Unscrew any screws holding the screen in place.

- Carefully disconnect cables attached to the screen using tweezers.

5. Install New Screen:

- Connect the new screen by reversing the disassembly steps.

- Ensure all cables are secure and screws are tightened.

6. Reassemble Device: Replace the back cover and power on your device to test functionality.

Fixing Dead Pixels

Dead pixels can sometimes be fixed using software tools that rapidly change colors in an attempt to "unstick" them:

1. Use pixel-fixing software available online.

2. Run it for several hours while monitoring results.

If this does not work, replacing the screen may be necessary.

Addressing Discoloration

Discoloration often requires professional help as it involves replacing internal components like polarizers or liquid crystal layers.

Dealing with Flickering Screen

1. Check all connections and cables for secure attachment.

2. If flickering persists, consider replacing the inverter board or backlight components.

Professional Repair Services

If DIY repairs seem daunting or if you lack experience, seeking professional help is advisable. Professional technicians have specialized tools and knowledge to handle complex repairs safely.

Benefits of Professional Repair

- Expertise in diagnosing issues accurately.

- Access to high-quality replacement parts.

- Warranty on repairs performed.

Preventative Measures

Taking care of your LCD screen can help prevent damage:

- Use protective cases for portable devices.

- Avoid placing heavy objects on screens.

- Keep devices away from extreme temperatures and moisture.

Additional Repair Techniques

In addition to basic repairs, there are specific methods for addressing minor issues without needing a full replacement:

Using Heat for Repairs

For pressure spots or flickering displays caused by loose connections:

1. Use a heat gun or hairdryer on a low setting held about 8–10 inches from the screen.

2. Warm up the area gently and then massage it lightly with a cloth. Be cautious not to overheat any part of the screen.

Toothpaste for Minor Scratches

Some users have reported success using non-abrasive toothpaste as a temporary fix for small scratches:

1. Apply a small amount of toothpaste onto a soft cloth.

2. Gently rub it into the scratch in circular motions.

3. Wipe clean with a damp cloth afterward.

Pressure Spot Repair

For pressure spots that do not affect functionality:

1. Gently massage around the spot using a soft cloth or your fingers in a circular motion.

2. This technique aims to redistribute liquid crystals within the display without applying too much pressure that could worsen damage.

Exploring Further Repair Techniques

As we dive deeper into LCD repair methods, understanding various techniques becomes crucial for effective troubleshooting and resolution of common issues encountered with these screens.

Advanced Techniques for Persistent Issues

For persistent problems such as flickering displays or consistent dead pixels that resist basic fixes:

Using Software Solutions

There are numerous software applications designed specifically for reviving stuck pixels by cycling through colors at rapid intervals:

1. Download pixel-fixing software compatible with your operating system.

2. Set it up according to instructions provided by developers.

3. Allow it to run continuously over affected areas for several hours or overnight for best results.

Gentle Tapping Method

Another method involves gently tapping around stuck pixels with a soft tool like a pencil eraser wrapped in cloth:

1. Ensure that you apply minimal pressure as excessive force could worsen pixel performance.

2. This technique may help dislodge any debris affecting pixel function without causing additional harm.

Backlight Issues

If your display has dimmed significantly despite brightness settings being adjusted correctly:

1. Inspect connections leading from power sources directly into backlights; ensure they are secure.

2. If you suspect backlight failure due to age or wear-and-tear:

- Consider replacing LED strips if applicable; this often requires disassembling parts of your device carefully following manufacturer guidelines found online specific to your model type.

Managing Color Distortion Problems

Color distortion issues may arise due either faulty settings within devices themselves or underlying hardware problems:

Adjust Display Settings

Begin by checking display settings through system preferences where color profiles can often be adjusted manually according user preferences:

1. Navigate through settings until you locate “Display” options available under control panels (varies based on operating system).

2. Experiment with different profiles until satisfactory results are achieved; sometimes reverting back defaults resolves unexpected distortions caused by accidental changes made previously unknowingly!

Inspect Internal Connections

If adjusting settings does not yield improvements:

1 . Open up device casing carefully following prior instructions mentioned earlier regarding safe disassembly practices ensuring no wires get pinched during process!

2 . Check all internal connections leading towards display panel itself; reseat any loose cables found along way ensuring everything is snugly connected before reassembling unit afterward!

Final Thoughts on Repairing Your LCD Screen

In conclusion, while repairing an LCD screen may initially seem daunting due its complexity involved—many common issues faced today can indeed be addressed effectively using proper techniques outlined throughout this guide! Whether opting for DIY approaches when feasible—or seeking professional assistance when necessary—understanding each step along way will empower users make informed decisions regarding their devices' maintenance needs moving forward! Regular upkeep combined with cautious handling practices will ultimately extend longevity while enhancing overall performance experienced daily!

Conclusion

Repairing an LCD screen is possible but varies in complexity depending on the type of damage. While some issues can be resolved through DIY methods, others may require professional intervention. Regular maintenance and careful handling can prolong your device's lifespan and reduce repair needs.

Related Questions

1. How much does it cost to repair an LCD screen?

The cost varies widely based on device type and damage extent but generally ranges from $50 to $300 for professional repairs.

2. Can I replace just the glass on my LCD screen?

In many cases, yes; however, if there is internal damage, a full screen replacement may be necessary.

3. What tools do I need for an LCD repair?

Basic tools include screwdrivers, plastic spudgers, tweezers, cleaning cloths, and possibly replacement parts depending on the issue.

4. How long does it take to repair an LCD screen?

DIY repairs can take anywhere from 30 minutes to a few hours depending on experience level and type of damage; professional repairs typically take a few days.

5. Are there any risks involved in DIY repairs?

Yes, risks include further damaging the device, voiding warranties, or causing electrical shorts if proper precautions aren't taken during disassembly and reassembly.

By taking proactive measures now—such as investing quality protective accessories like cases/screen protectors—you'll minimize risks associated potential future damages occurring down line!

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

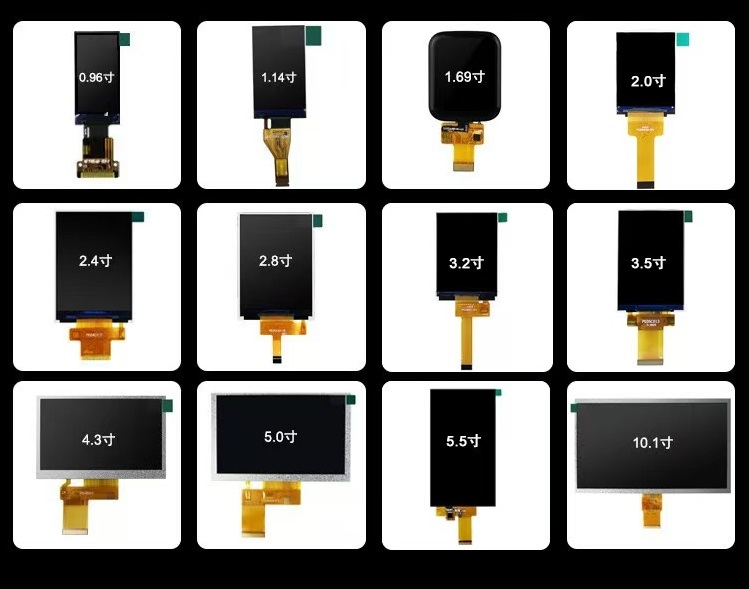

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch