News

Which Touch screen Is Used for Industrial Purpose?

Which Touch screen Is Used for Industrial Purpose?

Content Menu

● Introduction to Industrial touchscreen

>> Overview of Industrial touchscreen Technologies

● Which touchscreen Is Used for Industrial Purposes?

>> Applications of Industrial touchscreens

>> Integration with Other Technologies

● Key Considerations for Industrial touchscreen

● Common Challenges in Industrial Environments

>> Solutions to Environmental Challenges

● Future Developments in Industrial touchscreen

>> Role of AI in Industrial touchscreen

>> Impact of IoT on Industrial touchscreen

● FAQ

>> 1. What are the primary types of touchscreen used in industrial applications?

>> 2. How do resistive touchscreens differ from capacitive touchscreen in industrial use?

>> 3. What are the advantages of using optical imaging touchscreen in industrial settings?

>> 4. How do surface acoustic wave touchscreens perform in dusty environments?

>> 5.What features make projected capacitive touchscreen suitable for industrial applications despite their sensitivity?

Introduction to Industrial Touch screen

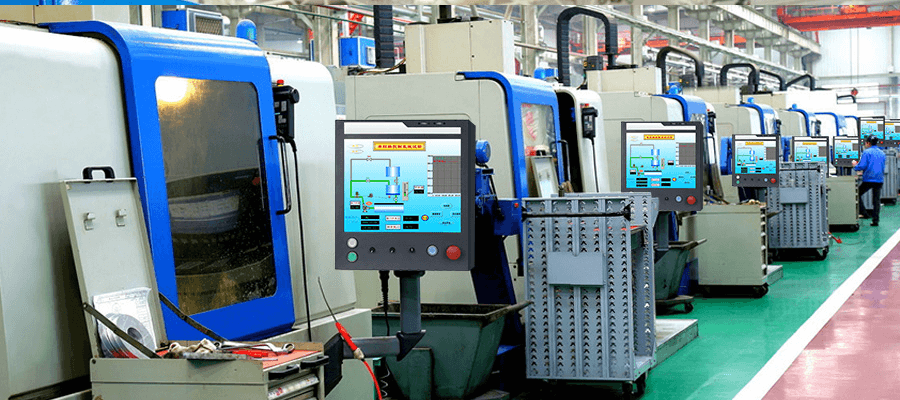

Industrial touch screen have become an integral part of various sectors, including manufacturing, healthcare, and transportation. These touchscreen are designed to withstand harsh environments and provide reliable performance under demanding conditions. The choice of touchscreen technology for industrial purposes depends on several factors, including durability, accuracy, and resistance to environmental factors such as water, dust, and extreme temperatures.

Overview of industrial touch screen Technologies

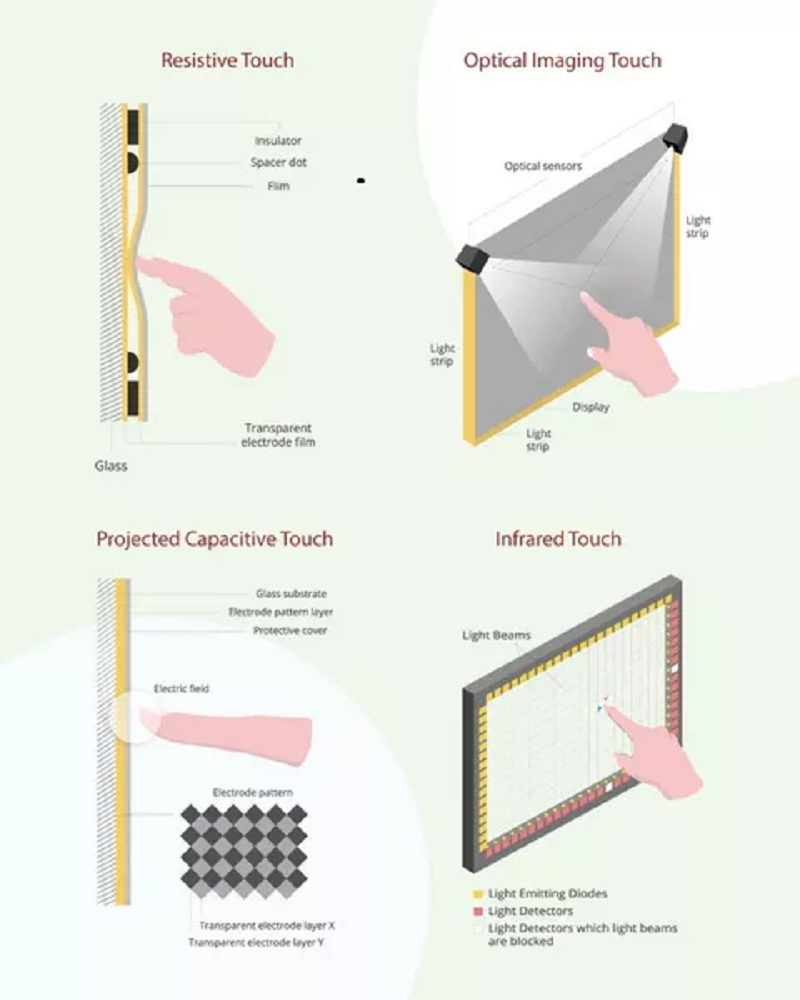

Industrial touch screen come in several types, each with its unique characteristics and applications. Resistive touchscreen are known for their durability and versatility, allowing use with gloved hands or styluses. They are commonly used in environments where precision and robustness are crucial. Capacitive touchscreens, particularly Projected Capacitive (PCAP), offer high accuracy and are suitable for applications requiring multi-touch functionality. However, they are more sensitive to environmental conditions and require bare fingers for operation.

Optical Imaging Touch screen use optical sensors to detect touch inputs, providing a high level of accuracy and multi-touch capabilities. They are often used in interactive displays and kiosks. Surface Acoustic Wave (SAW) touchscreens rely on sound waves to detect touch, offering high resolution but are sensitive to dust and water. Infrared (IR) touchscreen use IR sensors to detect touch, providing a durable and low-maintenance option.

Which Touch screen Is Used for Industrial Purposes?

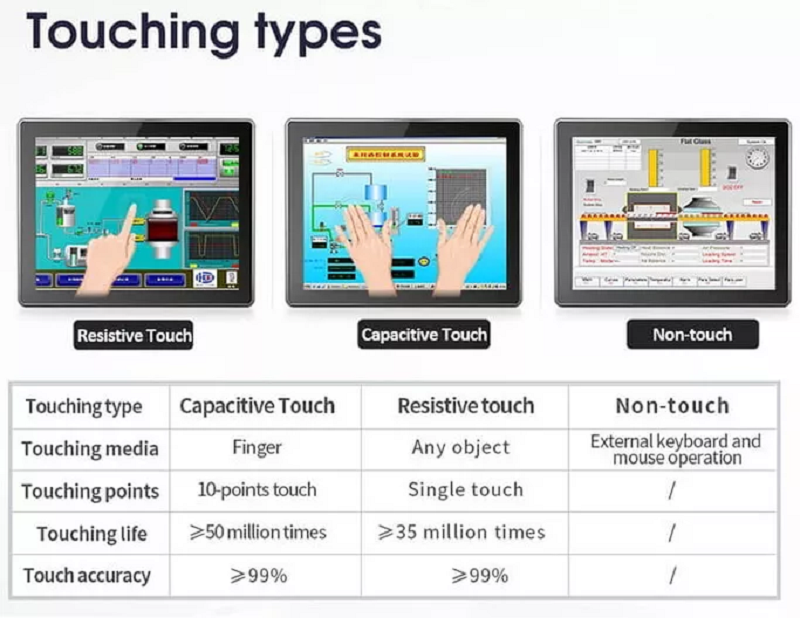

For industrial applications, the choice of touchscreen technology depends on the specific requirements of the environment and the tasks involved. Resistive touchscreen are widely used due to their durability and ability to function with various input methods. However, Projected Capacitive (PCAP) touchscreen are gaining popularity in industrial settings due to their high accuracy and multi-touch capabilities, despite requiring more protection against environmental factors.

Applications of Industrial Touch screen

Industrial touch screen are used in a variety of applications, including manufacturing, healthcare, and transportation. In manufacturing, they are used for controlling machinery and monitoring production processes. In healthcare, they are used in medical devices and patient information systems. In transportation, they are used in navigation systems and logistics management. Additionally, they are integrated into control panels for industrial automation, allowing operators to manage complex systems efficiently.

Integration with Other Technologies

Industrial touch screen are often integrated with other technologies to enhance their functionality. For example, they can be combined with Internet of Things (IoT) devices to provide real-time monitoring and control of industrial processes. This integration allows for remote access and management, improving efficiency and reducing downtime. Moreover, touchscreens can be linked with Artificial Intelligence (AI) systems to analyze data and predict maintenance needs, further optimizing industrial operations.

Key Considerations for Industrial Touch screen

When selecting a touchscreen for industrial use, several factors must be considered:

- Durability: The touch screen must be able to withstand harsh environments, including exposure to water, dust, and extreme temperatures.

- Accuracy: High accuracy is crucial for precise control and data entry.

- Multi-touch Capability: The ability to recognize multiple touch points simultaneously is important for complex applications.

- Environmental Resistance: The touchscreen should be resistant to noise interference and able to function under various lighting conditions.

Common Challenges in Industrial Environments

Industrial environments pose several challenges for touchscreen, including exposure to water, dust, and extreme temperatures. Additionally, these environments often involve noise interference from machinery, which can affect touchscreen performance. To overcome these challenges, industrial touchscreens are designed with advanced features such as water handling, anti-UV coatings, and robust cover lenses that meet international standards for impact resistance.

Solutions to Environmental Challenges

To address environmental challenges, manufacturers employ various solutions. For instance, waterproofing techniques are used to protect touchscreens from moisture, while anti-glare coatings help maintain visibility under bright lighting conditions. Thick cover lenses provide additional protection against physical impacts, ensuring the touchscreen remains operational even in rugged environments.

Future Developments in Industrial Touchscreens

As technology advances, industrial touchscreen are expected to integrate more sophisticated features. Artificial Intelligence (AI) and Machine Learning (ML) will play a significant role in enhancing touchscreen functionality, enabling predictive maintenance and real-time data analysis. Additionally, advancements in materials science will lead to more durable and environmentally resistant touchscreens, further expanding their applications in industrial settings.

Role of AI in Industrial Touchscreens

AI can enhance industrial touchscreens by providing predictive analytics, allowing for proactive maintenance and reducing downtime. AI algorithms can analyze usage patterns and detect anomalies, alerting operators to potential issues before they occur. This integration of AI with touchscreens will revolutionize industrial operations by making them more efficient and reliable.

Impact of IoT on Industrial Touch screen

The integration of IoT with industrial touch screen enables real-time monitoring and control of industrial processes. IoT devices can transmit data from sensors and machines to the touchscreen interface, allowing operators to monitor and adjust processes remotely. This connectivity enhances operational efficiency and reduces the need for manual intervention, making industrial processes safer and more efficient.

Conclusion

In conclusion, the choice of touchscreen technology for industrial purposes depends on the specific requirements of the application, including durability, accuracy, and environmental resistance. While resistive touchscreens are widely used due to their robustness, capacitive and optical imaging technologies are gaining traction for their high accuracy and multi-touch capabilities. Understanding the strengths and weaknesses of each technology is crucial for selecting the right touchscreen for industrial applications.

FAQ

1. What are the primary types of touchscreen used in industrial applications?

Industrial touchscreen primarily include resistive, capacitive (including projected capacitive), optical imaging, surface acoustic wave, and infrared technologies. Each type has its strengths and is chosen based on the specific needs of the application.

2. How do resistive touchscreen differ from capacitive touchscreens in industrial use?

Resistive touchscreen are more durable and can be used with gloved hands or styluses, making them suitable for harsh environments. Capacitive touchscreens, particularly PCAP, offer high accuracy and multi-touch capabilities but require bare fingers and are more sensitive to environmental conditions.

3. What are the advantages of using optical imaging touchscreen in industrial settings?

Optical imaging touchscreens provide high accuracy and support multi-touch functionality. They are resistant to wear and tear, making them suitable for interactive displays and kiosks. However, they may be more complex to implement compared to other technologies.

4. How do surface acoustic wave touchscreen perform in dusty environments?

Surface acoustic wave touchscreen are sensitive to dust and water, which can interfere with their operation. They are not ideal for environments where these conditions are prevalent, despite offering high resolution and accuracy.

5.What features make projected capacitive touchscreen suitable for industrial applications despite their sensitivity?

Projected capacitive touchscreen are made suitable for industrial applications through features like advanced water handling, thick cover lenses for impact resistance, anti-UV coatings, and algorithms that mitigate noise interference. These enhancements allow them to perform well in harsh environments.

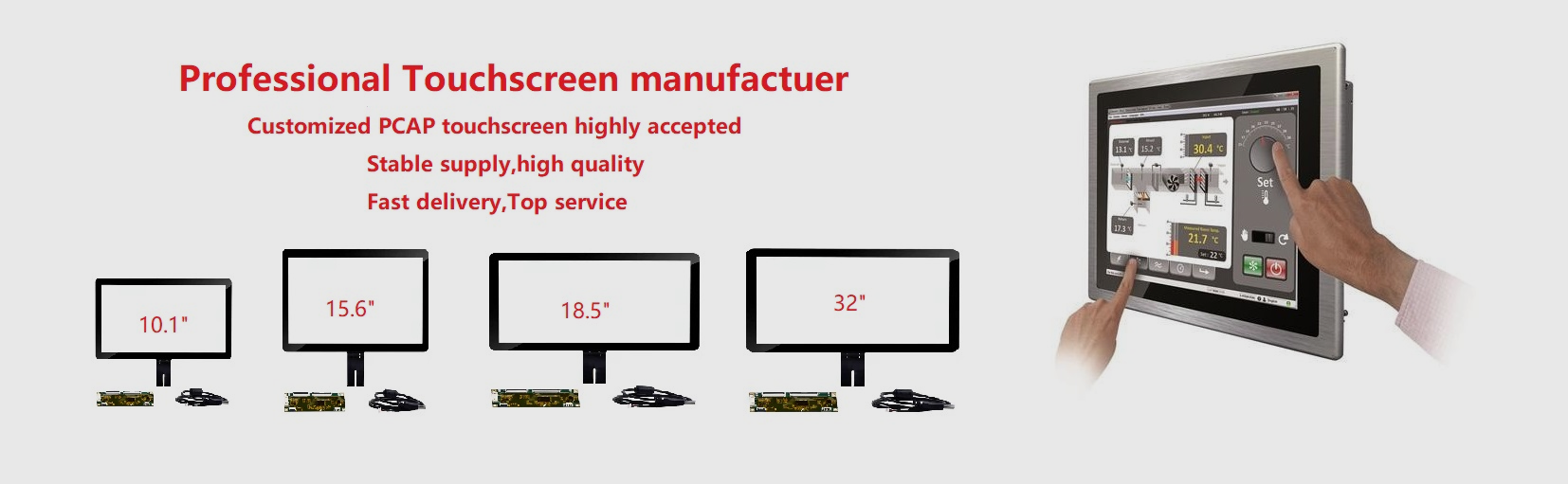

Choose DINGTouch, touch the future

DINGTouch is committed to providing customers with high-quality customized touch display solutions to help the widespread application of Deep Seek technology. Whether it is high-end AI equipment, medical monitoring systems, or intelligent industrial control, DINGTouch can provide the highest quality touch display customization services.

Please contact us at Sales@szdingtouch.com for more product information and technical support services.

DINGTouch - Touch the future, precise every moment!

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best Touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best Touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

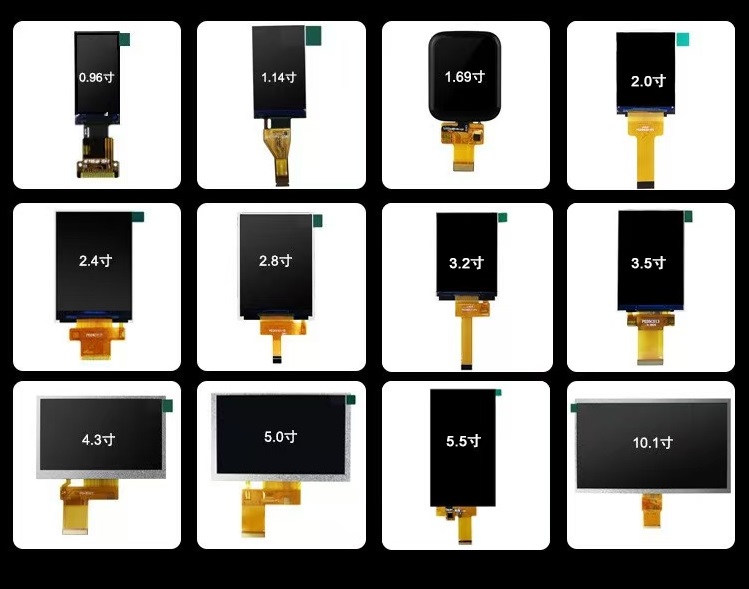

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch