News

How Do Touchscreen Industrial Panel PC Handle Harsh Industrial Conditions?

How Do touchscreen Industrial Panel PC Handle Harsh Industrial Conditions?

Content Menu

-

-

What types of touchscreens are used in industrial panel PC?

-

How do industrial panel PC protect against electromagnetic interference (EMI)?

Introduction

touchscreen industrial panel PC are designed to operate reliably in environments where standard computers would fail. These devices combine the computing power of traditional PC with the convenience of touch interfaces, making them ideal for industries such as manufacturing, automation, and logistics. Their ability to withstand harsh conditions—including extreme temperatures, dust, moisture, and vibrations—is crucial for maintaining continuous operation and reducing downtime in industrial settings.

Industrial panel PC feature rugged enclosures that meet IP ratings from IP65 to IP69K, ensuring protection against dust and water. They can function in temperatures ranging from -40°C to 85°C, thanks to fanless cooling systems that eliminate the need for moving parts, reducing maintenance and increasing longevity. The use of capacitive and resistive touchscreens allows operators to interact with the devices using gloves, styluses, or bare hands, enhancing usability across various industrial environments.

Handling Harsh Industrial Conditions

Industrial panel PC are engineered to withstand the toughest conditions in industrial environments. Their robust construction and protective enclosures ensure resistance to shocks and vibrations, often meeting military standards like MIL-STD-810G. Additionally, their fanless design helps maintain a stable operating temperature even in dusty areas, ensuring reliable performance in extreme environments.

1. Temperature Extremes and Cooling Solutions

Industrial panel PC are designed to function in extreme temperature conditions, a common challenge in many industries. The fanless cooling system dissipates heat without moving parts, reducing the risk of mechanical failure and increasing the device’s lifespan. This design also prevents dust accumulation, which can otherwise clog fans and cause overheating.

For example, Phoenix Contact provides industrial panel PC with high-performance fan-free designs, ensuring system reliability and robust performance in demanding environments.

2. Moisture and Dust Protection

The IP-rated enclosures of industrial panel PC provide excellent protection against moisture and dust, making them ideal for environments where standard electronics would fail. In outdoor applications or industrial facilities requiring water-based cleaning, these enclosures ensure continuous operation.

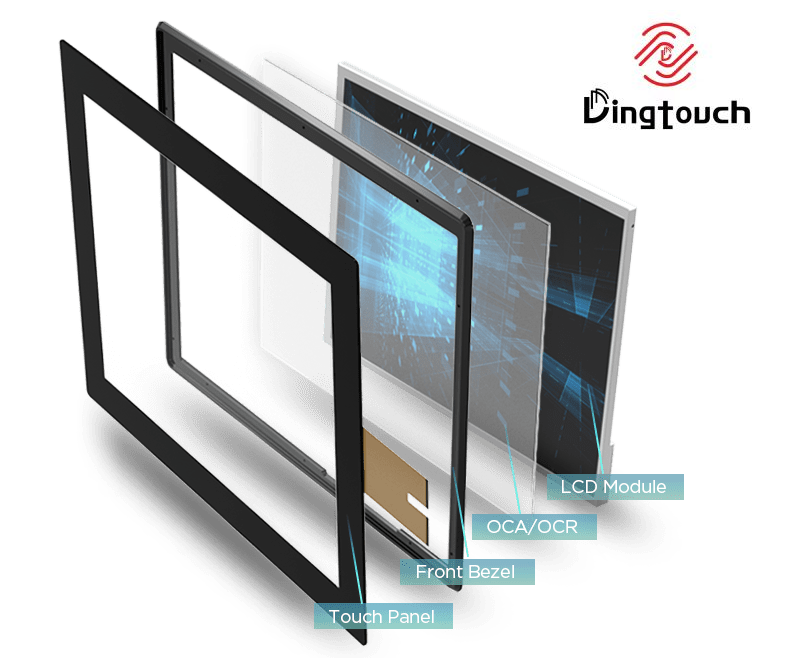

For instance, Amongo Display’s industrial panel PC integrate rugged casings with metal, aluminum, or steel front bezels, ensuring IP-rated protection in harsh conditions.

3. Vibrations and Mechanical Stress

Industrial settings often involve heavy machinery that generates vibrations, which can damage conventional devices. Industrial panel PC are built to withstand these vibrations, ensuring continuous operation and reducing maintenance costs.

For example, Interworld Electronics’ fanless panel PCs feature a rugged metal chassis, providing enhanced durability and resistance to mechanical stress.

4. Electromagnetic Interference (EMI) and Power Stability

In industrial environments, high-power devices generate electromagnetic interference (EMI), which can disrupt electronic equipment. Industrial panel PC are designed to comply with electromagnetic compatibility (EMC) standards, ensuring reliable operation even in high-EMI environments.

Additionally, stable power supply management is critical to preventing malfunctions, especially in applications requiring real-time data processing, such as manufacturing and automation.

5. Maintenance and Troubleshooting

Regular maintenance is essential to ensure the longevity of industrial panel PC. This includes:

-

Cleaning the screen regularly to prevent dust and grease buildup.

-

Troubleshooting issues like unresponsive touchscreens by checking connections, recalibrating the screen, and updating drivers.

-

The fanless design further reduces maintenance needs by eliminating dust buildup inside the device.

Future Trends and Innovations

The future of industrial panel PC is shaped by several key trends:

-

Thinner and more ergonomic designs improve usability, save space, and simplify maintenance.

-

Advancements in display technology, such as 4K resolution and curved displays, provide a clearer, more immersive user experience.

-

Integration of AI and IoT technologies enables real-time data processing and predictive maintenance, boosting automation.

-

Eco-friendly innovations, including OLED and MicroLED displays, reduce power consumption and extend device lifespan.

-

Emerging technologies like AR and VR enhance training and operational efficiency, expanding the use of industrial panel PC.

With increasing demand for automation and IoT solutions, the industrial PC market is expected to grow significantly, making embedded panel PC a crucial part of future industrial advancements.

Applications Across Industries

Industrial panel PC are widely used in various industries, including:

-

Factory automation – Acting as control centers for machinery and process monitoring.

-

Medical care – Designed for hygienic environments, resistant to frequent cleaning.

-

Retail – Integrated into kiosks and vending machines for customer interaction.

-

Transportation – Used for traffic monitoring and logistics management.

-

Energy and power – Applied in energy distribution and management systems.

Cost Savings and ROI

Industrial panel PC provide significant cost savings and return on investment (ROI) by:

-

Reducing maintenance costs with rugged designs that minimize repairs.

-

Operating in extreme environments, extending lifespan and reducing replacement needs.

-

Integrating multiple functions (control, monitoring, and data processing) into a single system, lowering operational costs.

-

Enhancing real-time data access, reducing human error, and increasing efficiency.

Enhanced Productivity

Industrial panel PC improve productivity by:

-

Providing intuitive touch interfaces that simplify operations.

-

Reducing human error with real-time feedback and data visualization.

-

Adapting to evolving needs through modular designs and software updates, ensuring long-term usability.

This flexibility makes industrial panel PC a vital component in maintaining competitiveness in rapidly changing industrial environments.

Conclusion

touchscreen industrial panel PC are essential for harsh industrial environments due to their rugged construction, high performance, and user-friendly interfaces. They enhance real-time data visualization, process management, and operational efficiency, reducing downtime.

With continued advancements in display technology, AI integration, and sustainability, industrial panel PC will continue to evolve, offering smarter and more interactive solutions for industrial applications. Their durability, versatility, and adaptability make them a critical component in modern industrial automation.

FAQ

-

What are the primary features of industrial panel PC?

Industrial panel PC are characterized by rugged construction, high-performance computing, and touchscreen interfaces designed to withstand extreme industrial conditions. -

How do industrial panel PC handle extreme temperatures?

They use fanless cooling systems to maintain stable operating temperatures, eliminating moving parts that can fail under extreme conditions. -

What types of touchscreens are used in industrial panel PC?

-

Resistive touchscreens – Respond to pressure, allowing use with gloves or styluses.

-

Capacitive touchscreens – Offer multi-touch functionality and higher sensitivity.

-

-

How do industrial panel PC protect against electromagnetic interference (EMI)?

They comply with electromagnetic compatibility (EMC) standards, incorporating shielding and EMI-resistant components. -

What maintenance is required for industrial panel PC?

Regular maintenance includes screen cleaning, checking connections, recalibration, and driver updates to ensure optimal performance.

![]() For more information, contact us at: Sales@szdingtouch.com

For more information, contact us at: Sales@szdingtouch.com

![]() DINGTouch – Touch the Future, Precision at Every Moment!

DINGTouch – Touch the Future, Precision at Every Moment!

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

RELATED NEWS

- Customer support2021-03-26

- Industrial Touch screen for Kiosks and V2021-04-08

- How are touchscreen manufactured2021-04-09

- Why a Touch Screen Overlay is a Good Ide2021-04-10

- Get Customized Touch Screen Panel in Onl2021-04-13

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch