News

The Future of LCD Display Manufacturing: Innovations, Emerging Technologies, and Market Trends

The Future of LCD Display Manufacturing: Innovations, Emerging Technologies, and Market Trends

Key Takeaways

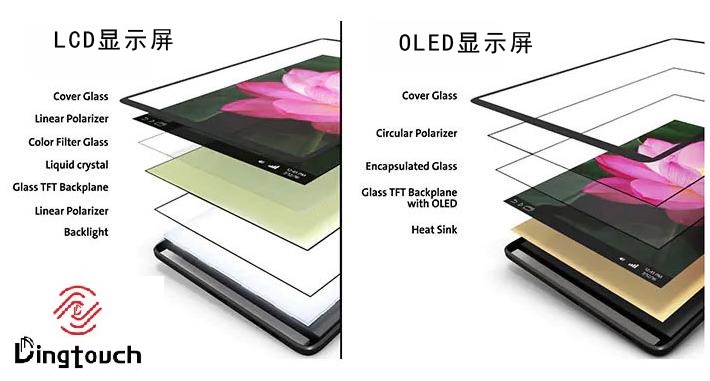

- OLED and MicroLED Integration: Enhancing brightness, color accuracy, and energy efficiency in LCD displays.

- Advanced touchscreen Technology: Improving user experience through enhanced responsiveness and durability.

- Industry 4.0 and Automation: Revolutionizing production with smarter processes that improve efficiency, reduce costs, and maintain high-quality standards.

- Quantum Dots and Flexible Materials: Creating displays that are more vibrant, versatile, and eco-friendly.

- Sustainability in Manufacturing: The industry's shift toward eco-conscious materials and processes to reduce environmental impact.

Emerging Innovations in LCD Display Manufacturing

OLED and MicroLED Integration:

OLED and MicroLED technologies are setting new benchmarks in display quality. Their integration into LCD manufacturing is pushing the boundaries of brightness, color accuracy, and energy efficiency, providing a more immersive viewing experience while reducing power consumption.

Advanced touchscreen Technology:

touchscreens are not only becoming more responsive but also more durable, enhancing the user experience in devices from smartphones to industrial machines. Technologies like capacitive touch, multi-touch, and optical bonding are elevating LCD screen to new heights in terms of precision and longevity.

Industry 4.0 and Smart Manufacturing:

Automation and data analytics are playing a crucial role in transforming the LCD production process. Through robotic systems, AI-powered data analysis, and IoT integration, manufacturers are optimizing production lines, leading to faster output, reduced costs, and higher quality control. The shift to Industry 4.0 is enabling an era of connected and intelligent factories.

Material Innovations and Sustainability

Quantum Dots: The Next Step in Color Accuracy

Quantum dot technology enhances color performance and brightness, making LCD display more vivid and life-like. This is expected to become a cornerstone of future display advancements, with market projections showing rapid adoption across multiple industries.

Flexible LCDs for Innovative Designs:

Flexible and ultra-thin LCD are opening up new possibilities for adaptable and portable designs. These displays can be integrated into wearables, foldable devices, and curved screen applications, creating exciting opportunities for designers and engineers alike.

Sustainable Manufacturing:

The trend toward sustainability is reshaping the way LCD display are made. Using eco-friendly materials and focusing on energy-efficient production processes are now key priorities for the industry. Moreover, recyclable LCD and reduced use of toxic substances are helping to mitigate environmental concerns.

Optimizing Manufacturing Efficiency

Automation for Faster, More Reliable Production:

The introduction of robotics and automated systems is increasing the speed and consistency of production, enabling manufacturers to scale up without sacrificing quality. Automated quality control and defect detection systems are critical in maintaining high standards.

Data Analytics and Predictive Maintenance:

The use of advanced data analytics allows manufacturers to predict failures and improve product quality by identifying issues early in the production process. This leads to reduced downtime, improved throughput, and lower operational costs.

Cleanroom Technology:

To maintain the quality and reliability of LCD, especially those with sensitive components, cleanroom environments are essential. These highly controlled spaces minimize contamination, ensuring that displays meet the strictest performance standards.

Challenges and Opportunities in the LCD Display Supply Chain

Supply Chain Challenges:

The LCD supply chain is facing increasing material costs and disruptions due to geopolitical tensions and resource scarcity. Materials like indium tin oxide and liquid crystals are essential but vulnerable to these supply chain challenges.

Logistics and Global Distribution:

Efficient logistics are critical for timely delivery of LCD components to manufacturers and consumers worldwide. The global transportation network plays a crucial role in maintaining a stable supply of raw materials and finished products.

Future Trends in LCD Display Applications

Transparent Displays:

Transparent LCDs are gaining traction, particularly in fields like augmented reality (AR) and virtual reality (VR). These displays offer new possibilities for creating immersive, interactive environments in both consumer electronics and commercial applications.

Applications in Healthcare and Automotive:

LCD displays in healthcare devices are becoming more energy-efficient with improved battery life. In the automotive industry, digital dashboards and infotainment systems are being optimized for better ergonomics and power savings.

Key Challenges Facing the LCD Industry

- Environmental Impact: As the demand for eco-friendly products increases, manufacturers are tasked with minimizing the carbon footprint and improving sustainability.

- Energy Efficiency: Reducing power consumption while enhancing brightness and color accuracy continues to be a major focus.

- Cost Management: Fluctuating material costs and market competition are constant pressures on manufacturers to innovate while maintaining profitability.

Conclusion: The Bright Future of LCD Manufacturing

The future of LCD display manufacturing is marked by significant advancements in technologies like OLED, MicroLED, quantum dots, and flexible materials. While challenges remain, the industry’s adaptability and innovation ensure that LCD technology will continue to thrive and evolve, offering exciting new possibilities across multiple sectors.

Frequently Asked Questions (FAQs)

-

What are the new technologies in LCD display manufacturing?

Key innovations include OLED, MicroLED, and Industry 4.0 automation, all of which are improving display quality and manufacturing efficiency. -

How are new materials improving LCD displays?

Quantum dots enhance color accuracy, while flexible materials allow for more adaptable designs, pushing the boundaries of what LCDs can do. -

What role does automation play in LCD manufacturing?

Automation speeds up production, reduces human error, and improves quality through consistent, data-driven processes. -

Who are the key players in the LCD supply chain?

Major players include Samsung Display, LG Display, AU Optronics, as well as suppliers of essential raw materials like indium tin oxide. -

What are the future trends in LCD display applications?

Future trends include transparent displays for AR/VR, healthcare applications for energy-efficient monitors, and advanced automotive displays with enhanced ergonomics. -

What challenges does the LCD industry face?

The industry faces challenges like environmental concerns, energy efficiency demands, and cost fluctuations in materials.Conclusion: The 5-Inch TFT LCD Display – A Beacon of Innovation and Excellence

The 5-inch TFT LCD display captures the essence of innovation, combining compact design, vivid visuals, and interactive functionality in one powerful package. While it may not be the apex of display technology, it undoubtedly represents a crucial milestone in the evolution of visual displays. As we continue to push forward, the 5-inch TFT LCD display will inspire future innovations, shaping the visual experiences of tomorrow.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

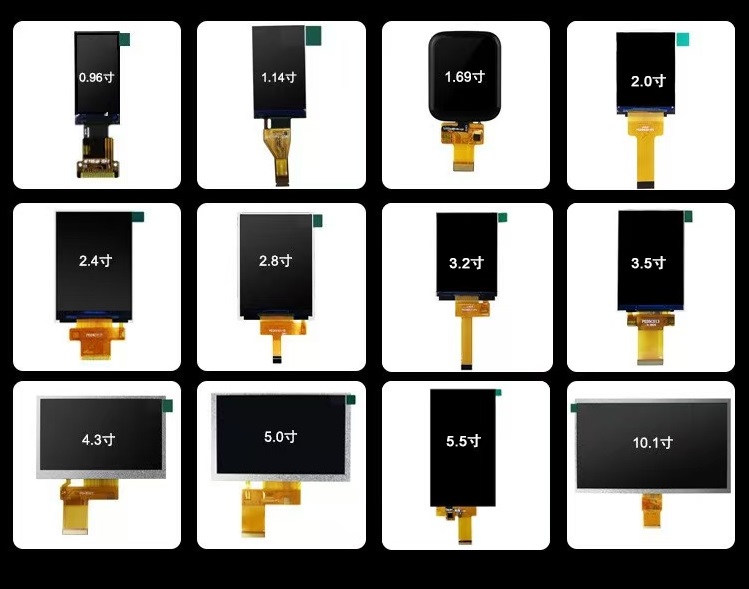

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch