News

Technical Overview and Production Applications of FPC and PCB

Technical Overview and Production Applications of FPC and PCB

1. FPC: Flexible Printed Circuit Board

FPC (Flexible Printed Circuit) is a type of circuit board that uses flexible substrates. It is known for being lightweight, thin, and bendable, making it widely used in portable electronics, wearable devices, automotive electronics, and more.

1.1 Types of FPC

FPCs can be categorized into two main types based on their structure:

-

Adhesive-Based FPC: The copper foil is bonded to the substrate using adhesive. This structure offers lower flexibility and weaker adhesion between copper and substrate. It has largely been phased out.

-

Adhesiveless FPC: The copper foil is directly laminated onto the substrate without glue, offering superior flexibility, better adhesion, and higher heat resistance. It is now the mainstream choice.

1.2 Classification by Layers

Based on the number of conductive copper layers, FPCs can be classified into:

-

Single-layer FPC

-

Double-layer FPC

-

Multi-layer FPC

Even for high-resolution applications, where circuitry is relatively simple, a double-layer FPC is often sufficient for signal transmission and routing, balancing performance and cost effectively.

2. PCB: Printed Circuit Board

PCB (Printed Circuit Board) is a rigid board composed of copper foil and insulating substrate. It is an essential component in electronic products, widely used in consumer electronics, communications, industrial control, medical devices, and more.

2.1 Layer Classification

-

Single-layer PCB

-

Double-layer PCB

-

Multi-layer PCB (ideal for complex and high-speed signal applications)

2.2 Substrate Materials

Common PCB base materials include:

-

Paper-based (phenolic paper resin boards)

-

Semi-glass fiber composites

-

Full-glass fiber boards (e.g., FR-4)

The choice of substrate material determines the board's mechanical strength, thermal stability, and electrical performance.

3. FPC/PCB Industry Extensions and Advanced Technologies

3.1 Mass Production Capability

Both FPC and PCB can be mass-produced with high precision and consistency, making them suitable for a wide range of high-integration electronic products.

3.2 Rigid-Flex PCB Production

Rigid-Flex PCBs combine the flexibility of FPC with the structural support of rigid PCBs. They are ideal for compact and mechanically complex devices such as foldable smartphones, military-grade equipment, and medical instruments.

3.3 COF (Chip on Film) Technology

COF is a packaging technology that mounts IC chips directly onto an FPC. It helps to reduce product thickness and increase integration, making it a key solution for ultra-thin display modules like OLED and Mini LED.

3.4 PCB-HDI (High-Density Interconnect) Production

HDI PCBs offer finer lines, smaller vias, and higher routing density. They are widely used in high-performance and compact devices such as smartphones, laptops, and high-speed communication systems.

4. Conclusion

As essential interconnection solutions in electronic devices, both FPC and PCB offer unique advantages in functionality, design flexibility, and manufacturing. With the growing demand for thinner, smaller, and more integrated products, advanced technologies like Rigid-Flex, COF, and HDI will continue to play an increasingly vital role in the development of next-generation electronics.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

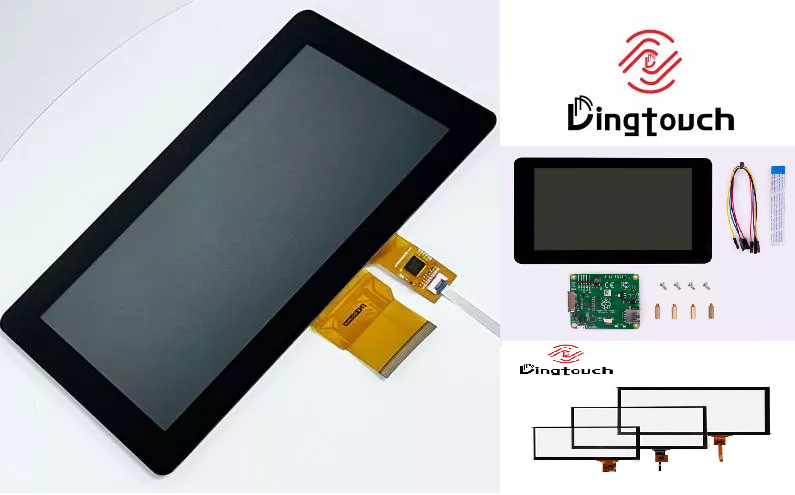

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

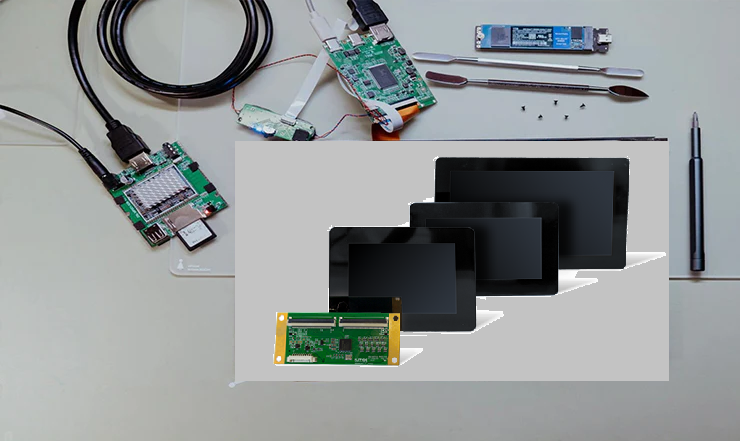

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

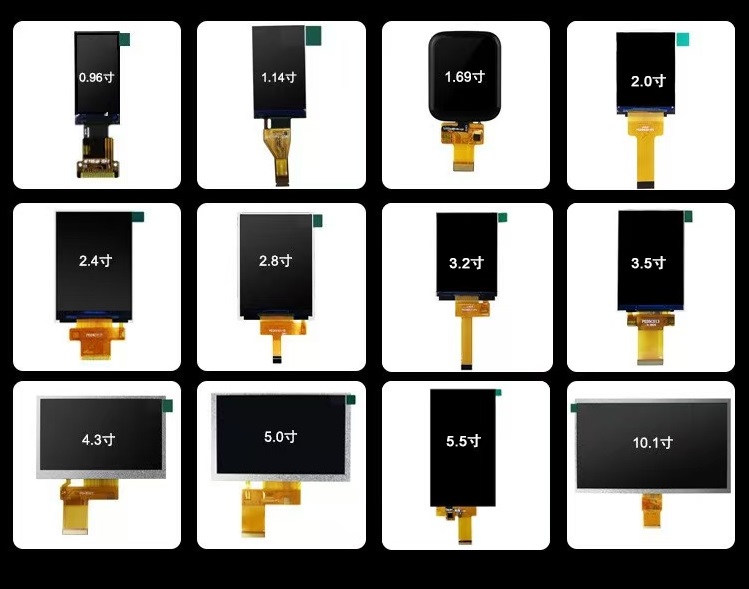

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch