News

Revolutionizing AOI Recognition Systems with Advanced Touchscreen Technology

Revolutionizing AOI Recognition Systems with Advanced touchscreen Technology

Contents

- Introduction: Overview of AOI Systems and touchscreen Technology

- Understanding Automated Optical Inspection (AOI)

- Importance of touchscreen Technology in AOI

- Advantages of Advanced touchscreen Systems

- Case Studies: Applications of touchscreens in AOI

- Challenges of Using touchscreens in AOI

- Implementation Strategies for Enterprises

- Future Trends in AOI and touchscreen Technology

- Conclusion

- Frequently Asked Questions (FAQs)

1. Introduction: Overview of AOI Systems and touchscreen Technology

In the field of electrical control systems, the combination of touchscreen technology with Automated Optical Inspection (AOI) systems marks a significant technological advancement. These systems are crucial for ensuring the quality and consistency of manufactured products, especially in the electronics industry. As industries strive for higher efficiency and precision, the integration of touchscreen interfaces with AOI technology is not just beneficial—it is transformative.

This article explores how advanced touchscreen technology enhances AOI recognition systems, analyzing its benefits and impact on the electrical control systems industry in detail.

2. Understanding Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) refers to the use of optical equipment and software to inspect electronic components. These systems play a key role in quality assurance, identifying defects in printed circuit boards (PCBs) and other electronic components. AOI systems use high-resolution cameras and complex algorithms to detect issues such as missing components, placement errors, and soldering defects.

The shift from manual inspection methods to AOI systems represents a leap in both efficiency and accuracy. However, the interface and ease of use have long been challenges, which are now being addressed by the introduction of touchscreen technology, changing how operators interact with these sophisticated systems.

3. Importance of touchscreen Technology in AOI

touchscreen technology has become ubiquitous across industries, offering a user-friendly interface. In AOI systems, touchscreens simplify navigation and control, enabling operators to perform complex tasks with ease and requiring less training. The importance of integrating touchscreens into AOI systems is evident in the following ways:

- User-friendly Interface: touchscreens offer easy-to-use interfaces, reducing the learning curve for operating AOI machines.

- Real-time Interaction: Operators can easily adjust settings, view inspection results, and respond to alerts in real time, enhancing operational efficiency.

- Customization: Many advanced touchscreen systems allow for personalized layouts, enabling users to prioritize the most relevant information.

4. Advantages of Advanced touchscreen Systems

Integrating advanced touchscreen technology into AOI systems brings numerous functional and performance improvements. Some key advantages include:

4.1 Enhanced Accuracy and Speed

touchscreens allow users to navigate through inspection results and settings faster, reducing decision-making time. This speed is critical in high-output manufacturing environments, where time is money.

4.2 Increased Operator Engagement

Interactive touchscreens are more engaging for operators than traditional button interfaces. This engagement encourages operators to take a more proactive approach to quality control, leading to better results.

4.3 Improved Data Visualization

Advanced touchscreens can display complex data in easily understandable formats, such as charts and dashboards, aiding in quick assessment and decision-making.

4.4 Simplified Maintenance and Troubleshooting

Many touchscreen systems come equipped with diagnostic tools that guide users through troubleshooting, making maintenance more efficient and less disruptive.

4.5 Remote Access Capability

With technological advancements, many touchscreen systems now offer remote access, allowing operators to monitor and control AOI processes from anywhere, increasing flexibility and responsiveness.

5. Case Studies: Applications of touchscreens in AOI

The transformative power of touchscreen technology in AOI systems can be seen in real-world applications. Here are a few notable case studies:

5.1 Case Study: A Leading Electronics Manufacturer

A well-known electronics manufacturer integrated touchscreen AOI systems into its production line, resulting in a 30% improvement in defect detection rates and significantly reducing operator training time due to the intuitive interface.

5.2 Case Study: Automotive Parts Supplier

An automotive parts supplier adopted touchscreen technology in its AOI processes, enabling real-time adjustments to inspection parameters. This flexibility improved quality control and reduced production delays.

5.3 Case Study: Consumer Electronics Innovator

A consumer electronics innovator used advanced touchscreen interfaces in its AOI system, facilitating better collaboration across teams. The user-friendly interface accelerated the sharing of inspection results, enhancing overall production efficiency.

6. Challenges of Using Touchscreens in AOI

While touchscreen technology offers many benefits, integrating it into AOI systems presents certain challenges:

6.1 Initial Investment Costs

The upfront costs of implementing advanced touchscreen systems can be considerable. Businesses must balance these costs with the long-term benefits in efficiency and quality.

6.2 Technical Issues

Touchscreens are susceptible to wear and tear, and technical issues can affect usability. Companies must establish robust support systems to address these challenges.

6.3 Operator Dependency

As systems become more intuitive, there is a risk of over-reliance on technology. Proper training and support must be provided to ensure operators remain skilled in traditional inspection methods.

7. Implementation Strategies for Enterprises

To successfully implement touchscreen technology in AOI systems, enterprises should consider the following strategies:

7.1 Assessing Needs and Goals

Before integrating new technology, companies must evaluate their specific needs and objectives. Understanding the desired outcomes will help in selecting the most appropriate touchscreen solutions.

7.2 Training and Support

Investing in comprehensive training programs ensures operators can effectively utilize the new systems. Continuous support is equally important to address issues as they arise.

7.3 Pilot Testing

Conducting pilot tests before full implementation allows companies to identify potential issues and fine-tune the system based on user feedback.

7.4 Continuous Improvement and Feedback Mechanism

Establishing feedback channels helps organizations continuously improve their AOI systems. Engaging operators in this process ensures the system evolves to meet their needs.

8. Future Trends in AOI and Touchscreen Technology

As technology continues to evolve, several trends are emerging that will shape the future of AOI systems and touchscreen technology:

8.1 Artificial Intelligence Integration

The integration of artificial intelligence (AI) with touchscreen technology will enhance AOI systems, enabling more complex defect recognition and predictive maintenance.

8.2 Enhanced Connectivity

With increasing connectivity options, future AOI systems may support cloud computing, allowing for more robust data analysis and real-time collaboration across teams.

8.3 Augmented Reality (AR) Interfaces

The combination of augmented reality interfaces with touchscreens could create immersive environments for operators, improving understanding and interaction with the inspection process.

8.4 Sustainability Initiatives

As industries push for sustainability, future AOI systems will focus more on energy efficiency and waste reduction, making touchscreen integration even more important.

9. Conclusion

Incorporating advanced touchscreen technology into AOI recognition systems represents a significant transformation in the electrical control systems industry. By enhancing user experience, increasing precision, and streamlining processes, these innovations pave the way for improved quality control and operational efficiency. As manufacturing continues to evolve, embracing these technologies will be crucial for companies aiming to stay competitive.

10. Frequently Asked Questions (FAQs)

Q1: What is an Automated Optical Inspection (AOI) system?

A1: AOI systems use optical equipment and software to detect defects in electronic components, ensuring product quality during manufacturing.

Q2: How does touchscreen technology enhance AOI systems?

A2: Touchscreen technology makes AOI systems more user-friendly, enabling faster navigation, real-time interaction, and improved data visualization.

Q3: What challenges arise from implementing touchscreens in AOI systems?

A3: Challenges include initial investment costs, potential technical issues, and operator over-dependence on technology.

Q4: What are some future trends in AOI technology?

A4: Future trends include AI integration, enhanced connectivity, AR interfaces, and a focus on sustainability.

Q5: How can businesses successfully implement touchscreen technology in AOI systems?

A5: Businesses should assess their needs, invest in training and support, conduct pilot tests, and establish continuous improvement mechanisms.

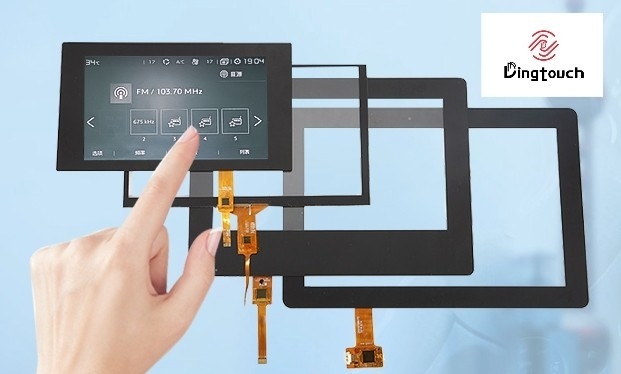

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best Touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch