News

Optical Bonding Explained: Enhancing Touchscreen Performance with DINGTouch

Optical Bonding Explained: Enhancing touchscreen Performance with DINGTouch

Introduction: Understanding Optical Bonding Technology

In modern touchscreen devices, display performance and durability are critical, especially for industrial, medical, and high-end consumer applications. Optical bonding is a technology that addresses these requirements by enhancing touchscreen readability, durability, and touch response. DINGTouch, as a leading expert in touchscreen manufacturing, provides cutting-edge optical bonding solutions tailored for various industries.

What is Optical Bonding?

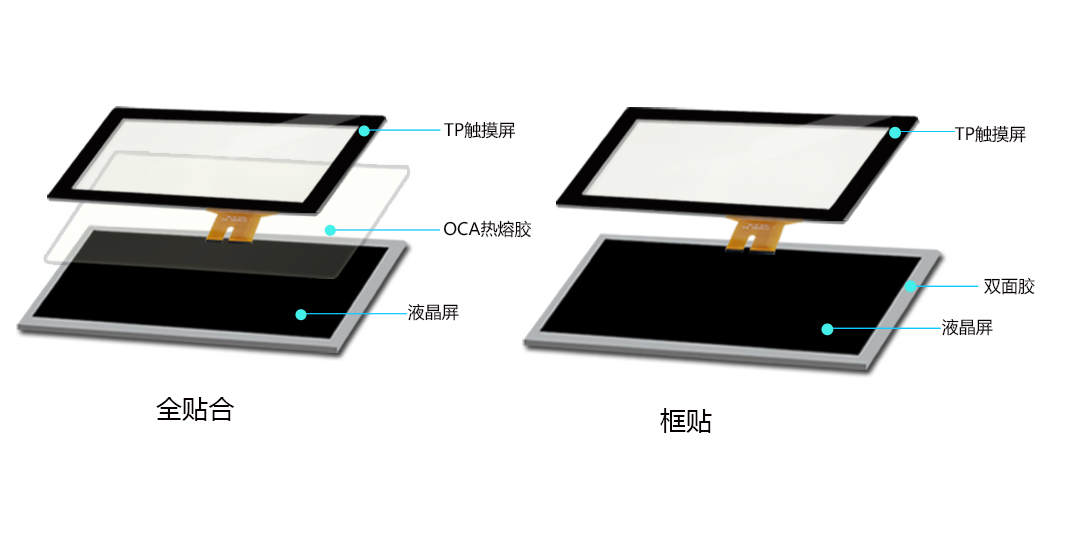

Optical bonding is the process of applying a layer of optical-grade adhesive between the display (LCD or OLED) and the touchscreen or cover glass. This process eliminates the air gap typically found between these layers, resulting in several performance benefits.

Key Benefits of Optical Bonding:

-

Improved Readability: Optical bonding significantly reduces internal reflections, enhancing screen clarity, brightness, and contrast. This is especially beneficial in environments with strong ambient light, where glare can be a major issue. By eliminating the air gap, optical bonding minimizes light refraction, allowing for clearer visibility even under direct sunlight.

-

Enhanced Durability: By filling the gap with adhesive, optical bonding adds structural strength to the display. This increased durability makes the screen more resistant to shocks, impacts, and vibrations, which is critical in rugged industrial or outdoor environments.

-

Better Touch Experience: Optical bonding improves touch accuracy and responsiveness by reducing the distance between the touch sensor and the display. This results in more precise touch recognition, providing a smoother and more responsive user experience.

-

Condensation and Dust Prevention: The elimination of the air gap prevents moisture, dust, and other contaminants from getting between the layers. This feature is crucial for devices used in humid or dusty environments where condensation could otherwise cause visibility issues.

-

Wide Viewing Angle: Optical bonding also enhances viewing angles by reducing reflections, ensuring the screen remains clear and readable from different perspectives. This is essential for devices that require visibility from multiple angles, such as medical monitors or public information kiosks.

DINGTouch Expertise in Optical Bonding:

DINGTouch offers customized optical bonding solutions that cater to specific industry requirements, whether it’s high brightness for outdoor displays, enhanced ruggedness for industrial use, or precise touch sensitivity for medical devices. Our advanced bonding techniques ensure that the displays maintain superior optical clarity, durability, and performance.

Applications of Optical Bonding in touchscreens:

- Industrial Control Panels: For use in harsh environments where dust, moisture, and impacts are prevalent.

- Medical Devices: Where precision touch and clear display readability are essential.

- Automotive Displays: Enhancing visibility under strong sunlight and ensuring robustness.

- Outdoor Digital Signage: Providing clear visibility and resistance against environmental conditions.

Conclusion: The Future of Display Technology with DINGTouch

Optical bonding is more than just a technological enhancement; it’s a game-changer for industries demanding superior display performance. DINGTouch expertise in this area ensures that our touchscreen solutions provide unmatched clarity, durability, and touch responsiveness, meeting the needs of the most demanding applications.

For businesses looking to enhance their touchscreen devices with optical bonding, DINGTouch is your trusted partner for high-quality, reliable solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

RELATED NEWS

- Customer support2021-03-26

- Industrial Touch screen for Kiosks and V2021-04-08

- How are touchscreen manufactured2021-04-09

- Why a Touch Screen Overlay is a Good Ide2021-04-10

- Get Customized Touch Screen Panel in Onl2021-04-13

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch