News

Mechanical Design of TFT LCD Display Modules

Mechanical Design of TFT LCD Display Modules

Mechanical Design of TFT LCD Display Modules

Engineering Strength, Thermal Reliability, and Dust Protection for Long-Term Performance

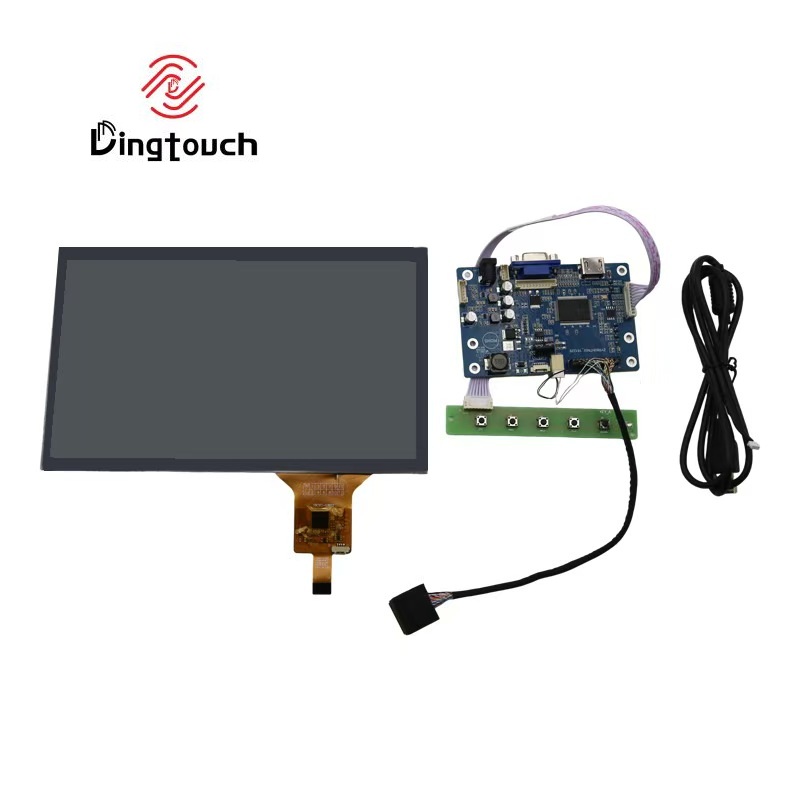

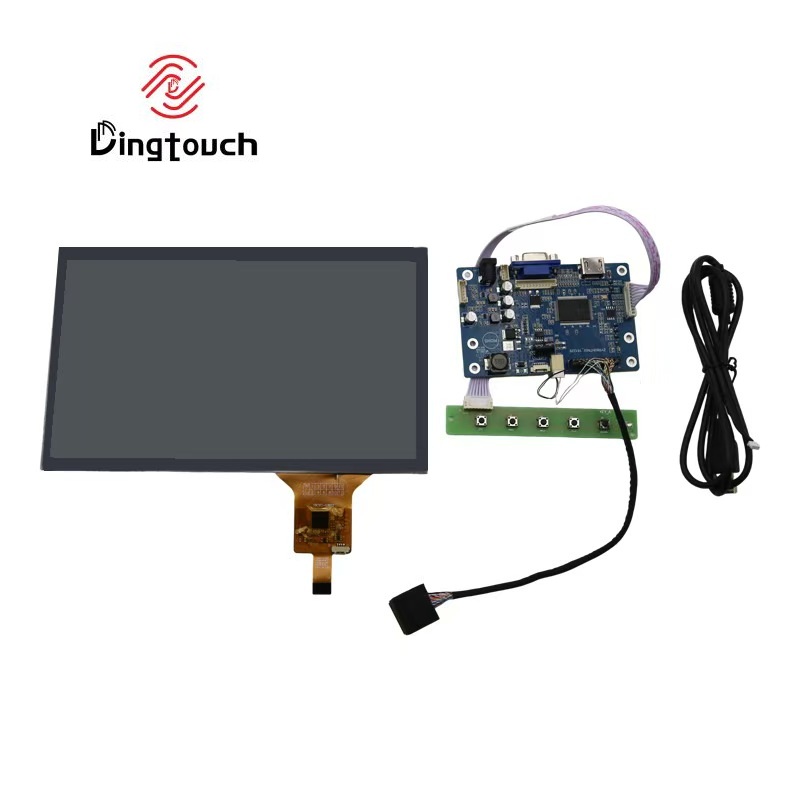

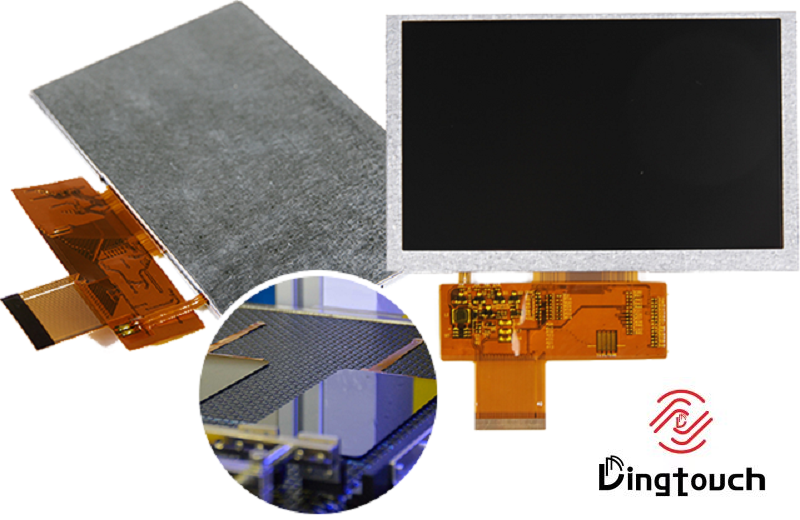

In modern electronic systems, TFT LCD display modules are not only visual interfaces but also precision-engineered structural components. Their mechanical design directly affects reliability, lifespan, image quality, and overall system stability.

At DINGTouch, mechanical design is treated as a multidisciplinary engineering task—integrating material mechanics, thermodynamics, and environmental protection principles. This article explores the mechanical design of TFT LCD display modules from three critical perspectives: structural strength, thermal management, and dust protection.

1. Structural Strength Design: Ensuring Reliability Under Shock and Vibration

During operation, transportation, and installation, TFT LCD modules are frequently exposed to vibration, mechanical shock, and external stress. A robust structural design is essential to prevent deformation, cracking, or functional failure.

1.1 Vibration and Shock Resistance Strategy

LCD modules must comply with defined vibration and shock test standards. Through testing, engineers identify weak points, analyze failure mechanisms, and refine the structure accordingly.

To reduce development risk and design iteration costs, DINGTouch applies failure prediction based on long-term project experience, implementing reinforcement solutions during the early design stage.

1.2 Core Reinforcement Approaches

Interlocking Structural Design

A high-rigidity LCD module depends on tightly connected components. Structural parts must be mechanically interlocked to function as a unified body.

Key practices include:

-

Secure interlocking between front frame and rear housing

-

Stable encapsulation of internal materials

-

Common methods: screws, snap-fit structures, industrial adhesive tapes

This approach significantly improves resistance to external mechanical stress.

Localized Reinforcement Design

Structural weak points require targeted reinforcement. Common reinforcement techniques include:

-

Structural stretching

-

Reinforcing ribs

-

Folded edges

-

Triangular support structures

These methods enhance stiffness without unnecessary weight increase.

2. Thermal Management Design: Extending Display Life and Stability

As TFT LCD modules operate for extended periods, heat accumulation becomes inevitable. Poor heat dissipation can accelerate aging, reduce brightness, and compromise display uniformity.

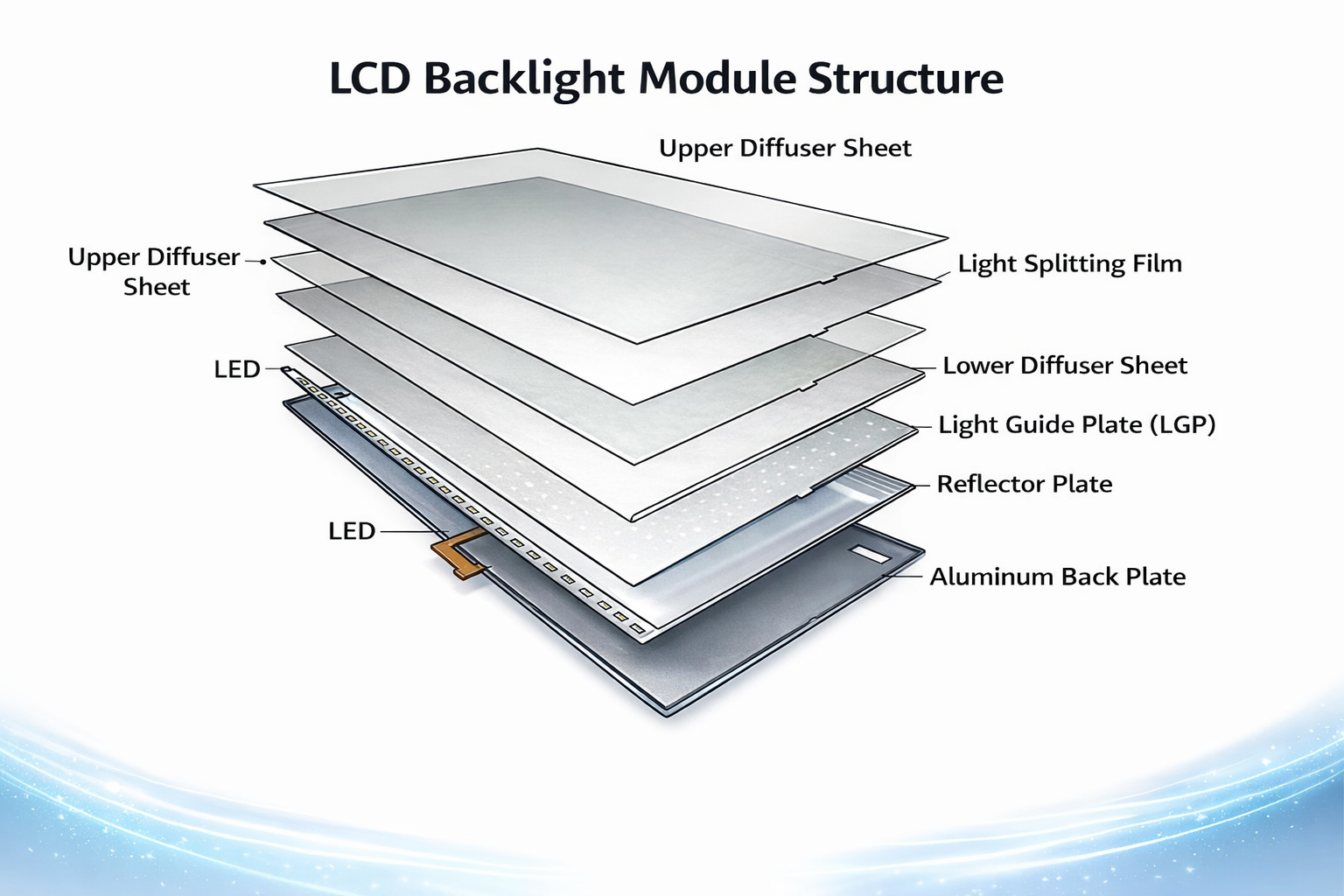

2.1 Heat Generation Sources and Risks

The primary heat sources include:

-

Backlight units (especially LED light sources)

-

Power circuits and driving components

Excessive heat may lead to:

-

Reduced luminous efficiency

-

Optical film deformation or wrinkling

-

Uneven backlight distribution

-

Display instability during aging tests

2.2 Effective Heat Dissipation Methods

Thermal management relies on three fundamental mechanisms:

-

Conduction

-

Convection

-

Radiation

Material selection plays a decisive role. Metal materials, especially magnesium-containing aluminum alloys, are widely used due to their excellent thermal conductivity and lightweight properties.

2.3 Optimizing Backlight Thermal Performance

Improving LED luminous efficiency is one of the most effective heat-reduction strategies. Higher efficiency means less energy converted into heat.

Today’s advanced LED power drivers can reach up to 99% efficiency, significantly reducing thermal load and improving system reliability.

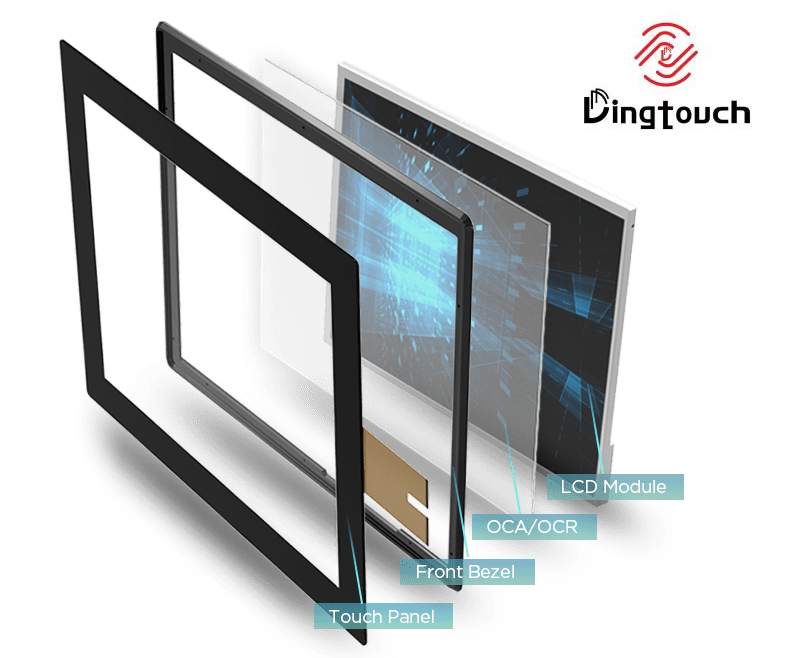

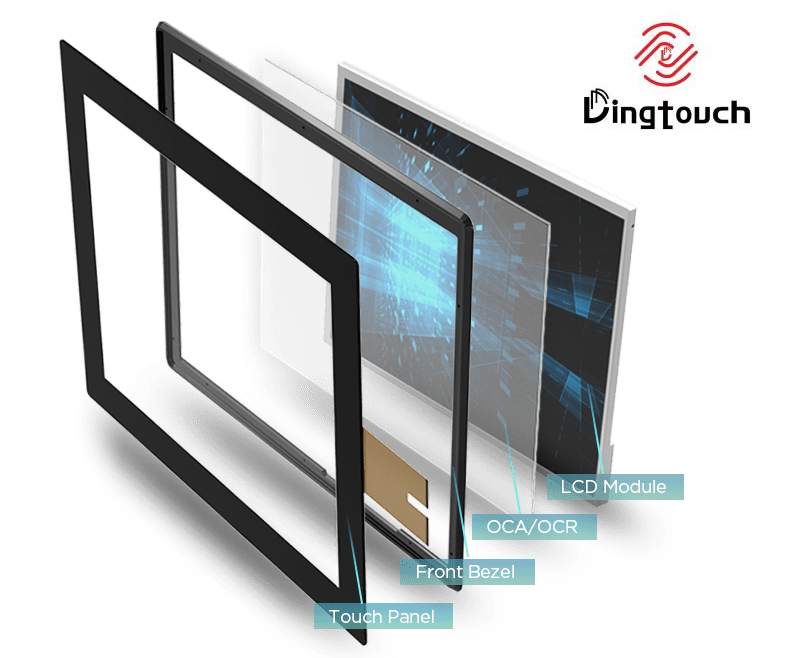

3. Dust Protection Design: Preserving Optical Quality

Dust intrusion is one of the most common causes of display defects during transportation or end-user operation.

3.1 Dust-Sensitive Areas in LCD Modules

Dust is most visible and harmful when it settles:

-

Behind the display panel

-

On the surface of optical films

-

Between optical film layers

Even minimal contamination can cause visible dark spots or uneven brightness.

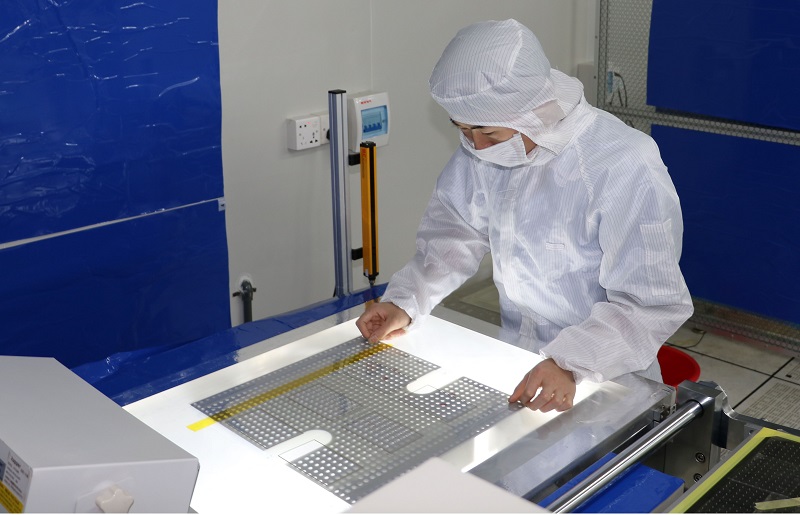

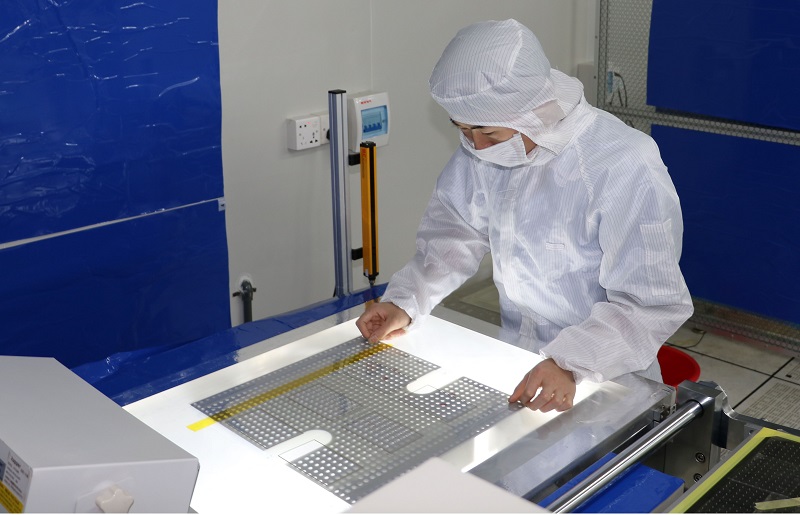

3.2 Sealed Structural Design

The most effective dust prevention strategy is a fully sealed module structure.

DINGTouch LCD modules undergo strict dust chamber testing, ensuring that no foreign particles enter the optical area under defined conditions.

A well-designed sealed structure not only improves display quality but also enhances long-term environmental reliability.

Conclusion: Engineering Excellence Behind Every TFT LCD Module

The mechanical design of TFT LCD display modules is a complex yet crucial process. By integrating:

-

Structural strength design

-

Advanced thermal management

-

Effective dust protection

DINGTouch ensures every display module delivers long-term reliability, consistent performance, and superior visual quality—even in demanding industrial and commercial environments.

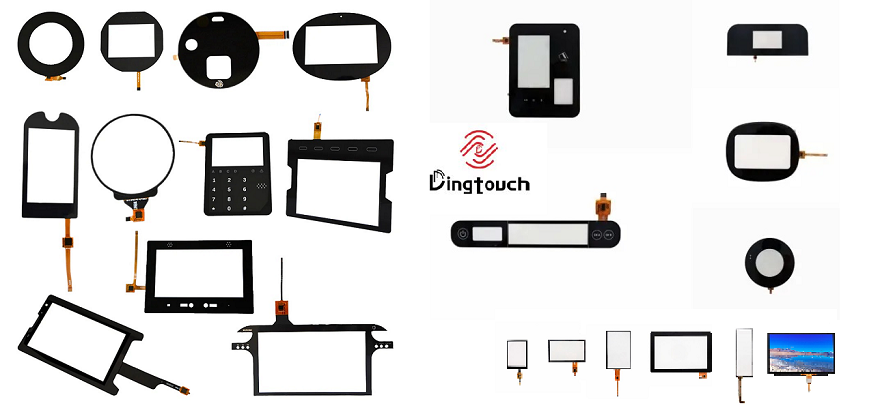

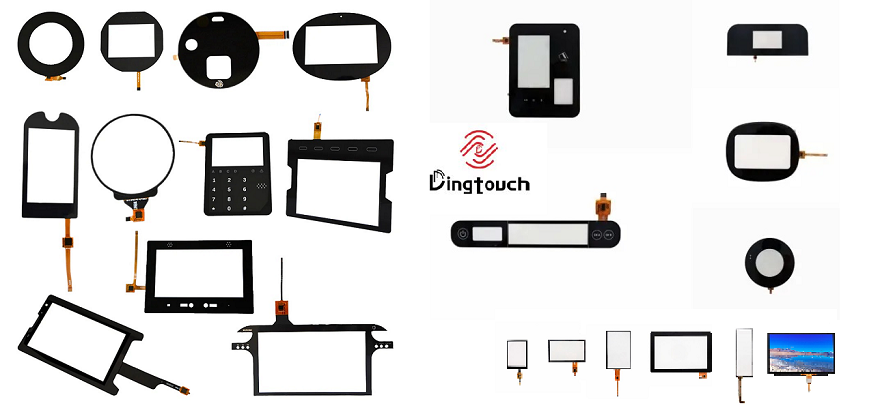

Partner with DINGTouch for Custom Capacitive Touch Solutions

Ready to build a custom TFT LCD or capacitive touch display tailored to your application?

At DINGTouch, we bring your ideas to life with:

-

Precision mechanical engineering

-

Premium materials

-

Industry-leading manufacturing standards

-

Full customization support

Email: sales@szdingtouch.com

Website: www.szdingtouch.com

DINGTouch — Your Trusted Partner in Custom Touch Display Engineering.

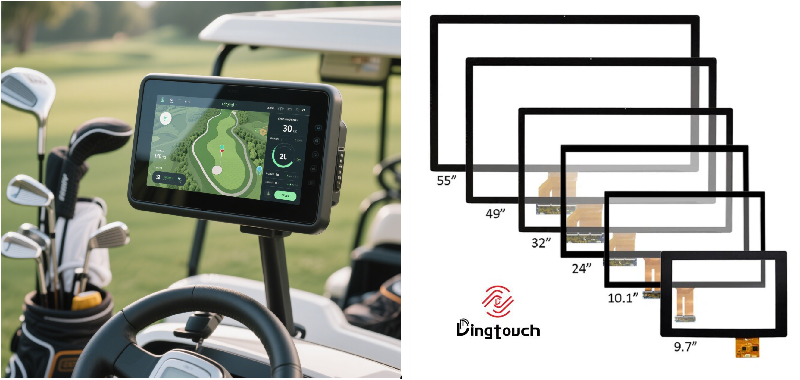

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as 5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedicaldisplay, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions,#Waterproof Touchscreen,

#highbrightnessLCD, #sunlightreadabledisplay,#industrialLCDbacklight, #outdoor displaymodule, #customLCDsolution, #1000–2000nitsdisplay, #DINGTouchtouchscreen.

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch