News

How To Make Capacitive Touch Screen at Home?

How To Make capacitive touch screen at Home?

Content Menu

● Understanding Capacitive Touch Technology

>> 1. Preparing the Touch Panel

>> 2. Setting Up the Microcontroller

>> 3. Testing Your Touch Screen

● Applications of Capacitive Touch Screens

● Future Trends in Capacitive Touch Technology

>> 1. What materials can I use for my capacitive touch screen?

>> 2. How does a capacitive touch screen work?

>> 3. Can I make a multi-touch capacitive screen at home?

>> 4. What microcontrollers are suitable for this project?

>> 5. What software do I need for programming my capacitive touch screen?

Creating a capacitive touch screen at home can be an exciting project for tech enthusiasts and DIYers. Capacitive touch screens are widely used in smartphones, tablets, and other devices due to their high sensitivity and multi-touch capabilities. This article will guide you through the process of making your own capacitive touch screen, including necessary materials, step-by-step instructions, enhancements, and troubleshooting tips.

Understanding Capacitive Touch Technology

Capacitive touch screens work by sensing the electrical properties of the human body. When a finger touches the screen, it alters the electrostatic field, allowing the device to detect the touch's location. This technology is widely used because of its responsiveness and ability to recognize multiple touch points simultaneously.

Principle of Operation

Capacitive touch screens are primarily composed of three layers: a conductive layer, an insulating layer, and a sensing layer. The conductive layer typically uses transparent conductive materials such as Indium Tin Oxide (ITO) film, which has excellent conductivity and light transmittance. The insulating layer separates the conductive layer from the sensing layer, ensuring safety and stability. The sensing layer is responsible for detecting user interactions.

When a finger approaches or touches the screen, it changes the capacitance distribution on the sensing layer. This change is captured by the touch screen control system, which processes the signals to determine the location of the touch. The system can also identify gestures like swiping or pinching by analyzing multiple touch points.

Materials Needed

Before starting your project, gather the following materials:

- Conductive Material: Aluminum foil, conductive fabric, or copper tape.

- Insulating Material: Plastic or glass panel.

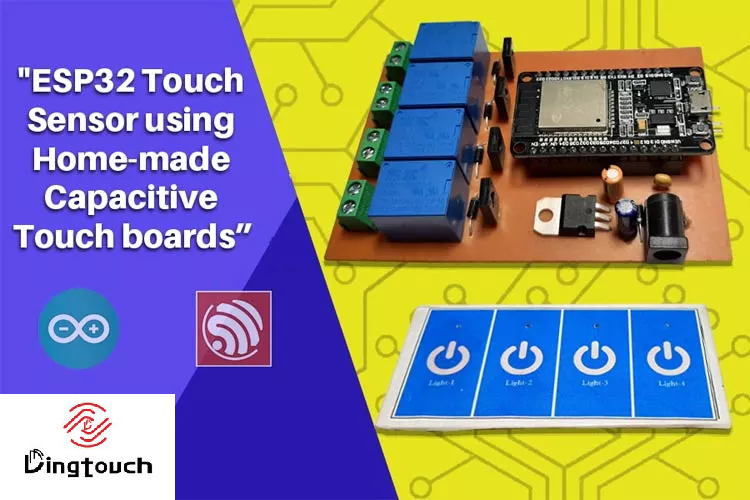

- Microcontroller: Arduino or similar microcontroller for processing touch inputs.

- Wires: For connections.

- Breadboard: For prototyping the circuit.

- Power Supply: To power your microcontroller and sensors.

- Software: Arduino IDE or similar software for coding.

Step-by-Step Instructions

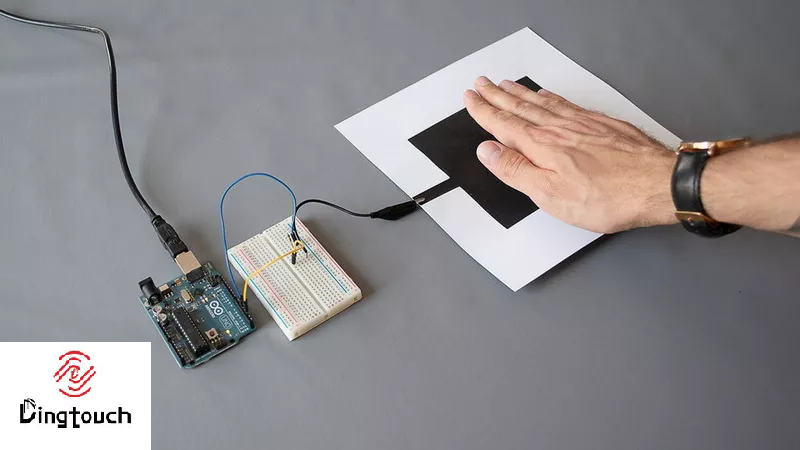

1. Preparing the Touch Panel

To create a capacitive touch screen, you need a flat surface that can act as the touch panel. Here's how to prepare it:

- Cut a piece of glass or acrylic to your desired size.

- Apply a layer of conductive material (like aluminum foil) on one side of the panel. Ensure it covers the area where you want to detect touches.

2. Setting Up the Microcontroller

Next, you need to set up your microcontroller to read inputs from the capacitive touch panel.

- Connect the conductive layer to one of the analog pins on your microcontroller.

- Use jumper wires to connect the ground pin of your microcontroller to the conductive layer.

3. Testing Your Touch Screen

After connecting everything:

- Power up your microcontroller and observe its behavior when you interact with the capacitive panel.

- Touch different areas of your capacitive panel and observe changes in values using a serial monitor if applicable.

Enhancements and Variations

Once you have successfully created a basic capacitive touch screen, consider these enhancements:

- Multi-Touch Capability: Use multiple sensors connected to different pins for multi-touch functionality.

- Visual Feedback: Integrate LEDs that light up based on touch input for visual feedback.

- Advanced Gestures: Program complex gestures like swiping or pinching by analyzing multiple sensor inputs.

Troubleshooting Tips

If your capacitive touch screen isn't functioning as expected:

- Ensure that there is good contact between the conductive material and the microcontroller.

- Check connections for any loose wires or faulty components.

- Experiment with different sizes and shapes of conductive materials to improve sensitivity.

Applications of Capacitive Touch Screens

Capacitive touch screens have numerous applications across various fields:

- Consumer Electronics: Widely used in smartphones, tablets, and laptops for user interfaces due to their high sensitivity and multi-touch capabilities.

- Industrial Control Systems: Used in machinery control panels where operators can interact with machines through intuitive gestures.

- Home Automation: Implemented in smart home devices allowing users to control lighting, heating, and security systems with simple touches.

- Medical Devices: Used in medical equipment for patient monitoring systems where quick access is crucial.

Future Trends in Capacitive Touch Technology

As technology advances, capacitive touch screens are evolving with new features:

- Flexible Displays: Research is ongoing into flexible touchscreen technology that can be integrated into various surfaces and products.

- Enhanced Sensitivity: Future developments may lead to even more sensitive screens capable of detecting lighter touches or gestures without direct contact.

- Integration with AI: The incorporation of artificial intelligence could allow for more intuitive interactions based on user behavior patterns.

Conclusion

Creating a capacitive touch screen at home is not only feasible but also a rewarding project that enhances your understanding of electronics and programming. With basic materials and some coding skills, you can build a functional touch interface suitable for various applications. As you gain experience, feel free to explore more advanced features and integrations that can enhance your projects further.

Related Questions

1. What materials can I use for my capacitive touch screen?

You can use aluminum foil, conductive fabric, or copper tape as conductive materials along with a glass or acrylic sheet as an insulating surface.

2. How does a capacitive touch screen work?

Capacitive touch screens detect touch by sensing changes in electrostatic fields caused by conductive objects like human fingers.

3. Can I make a multi-touch capacitive screen at home?

Yes, by using multiple sensors connected to different pins on your microcontroller, you can create a multi-touch capable interface.

4. What microcontrollers are suitable for this project?

Popular choices include Arduino boards (like Arduino Uno or Nano) due to their ease of use and extensive community support.

5. What software do I need for programming my capacitive touch screen?

You will need Arduino IDE or similar software compatible with your chosen microcontroller for coding and uploading sketches.

By following these steps and guidelines, you can successfully create your own capacitive touch screen at home while gaining valuable hands-on experience in electronics! This project not only enhances technical skills but also opens doors for further exploration into innovative applications in technology today.

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

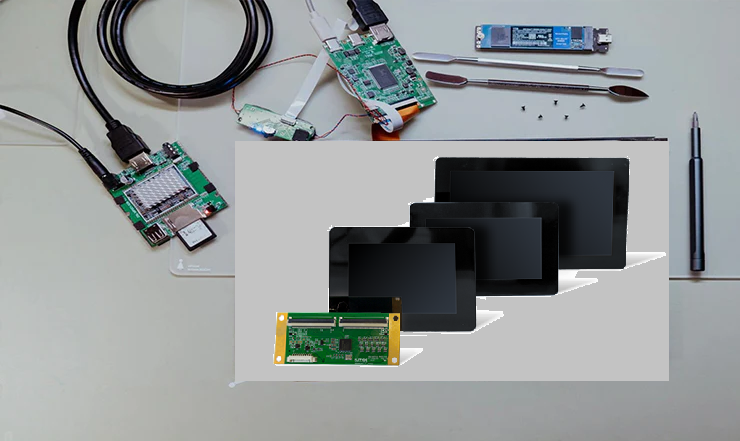

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch