News

Laser Direct Ablation (LDA): Precision Patterning for Advanced Touchscreen

Laser Direct Ablation (LDA): Precision Patterning for Advanced touchscreen

Laser Direct Ablation (LDA): Precision Patterning for Advanced touchscreen

What is Laser Direct Ablation?

Laser Direct Ablation (LDA) is a cutting-edge, maskless microfabrication technique that uses a focused laser beam to directly remove material—such as transparent conductive films—from a substrate surface. In capacitive touch screen manufacturing, LDA is primarily used to create fine electrode patterns on materials like ITO, metal mesh, or silver nanowires, offering a flexible and cost-effective alternative to traditional photolithography.

How LDA Works

LDA involves directing a high-energy laser beam at the conductive layer on the touchscreen substrate. By precisely controlling the laser’s:

-

Power

-

Wavelength

-

Pulse duration

-

Scanning speed

manufacturers can selectively remove conductive material to form intricate electrode structures without using photomasks or wet chemicals.

Typical laser sources used:

-

UV lasers (355 nm) – for high precision and minimal thermal damage

-

Green lasers (532 nm) – for moderate absorption by transparent conductors

-

Femtosecond lasers – for ultra-high precision and delicate materials

Advantages of LDA in touchscreen Fabrication

✅ Maskless Fabrication

Eliminates the need for costly and time-consuming photomasks, enabling rapid design iteration and prototyping.

✅ High Precision

Supports patterning of fine lines down to 10–20 µm, suitable for high-resolution touch sensors.

✅ Non-Contact Process

Reduces mechanical stress and material distortion—ideal for flexible substrates such as PET and PI.

✅ Customizable and Scalable

Perfect for small- to mid-volume production and custom-size touch panels, allowing dynamic changes to layout and geometry.

✅ Cleaner and Eco-Friendly

Minimizes use of harsh chemicals and reduces waste compared to traditional etching methods.

Applications of LDA in Capacitive Touch Technology

-

Industrial Touch Panels: For large, rugged touch interfaces with customizable sensor layouts

-

Flexible & Foldable Displays: Ideal for wearable and bendable screens

-

Automotive touchscreens: Enables curved or irregular designs in smart dashboards

-

Medical Devices: Clean, chemical-free production of high-precision touch sensors

Challenges and Considerations

While LDA offers significant advantages, it also presents challenges:

-

Thermal Effects: Improper calibration can lead to substrate warping or material damage.

-

Equipment Cost: High-quality laser systems require upfront investment.

-

Throughput: May be slower than roll-to-roll or large-area photolithography for ultra-high-volume production.

However, as laser systems become more affordable and advanced, LDA is increasingly adopted for mid-scale, high-value, or customized capacitive touch solutions.

Conclusion: A Flexible and Future-Proof touchscreen Patterning Solution

Laser Direct Ablation is reshaping how manufacturers create fine conductive patterns in capacitive touchscreens. With its flexibility, precision, and eco-friendliness, LDA is especially valuable for today’s demand for custom, curved, or flexible touch devices. As industrial applications push for faster prototyping, smarter designs, and greener production, LDA stands out as a powerful enabler of innovation in next-generation display technology.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

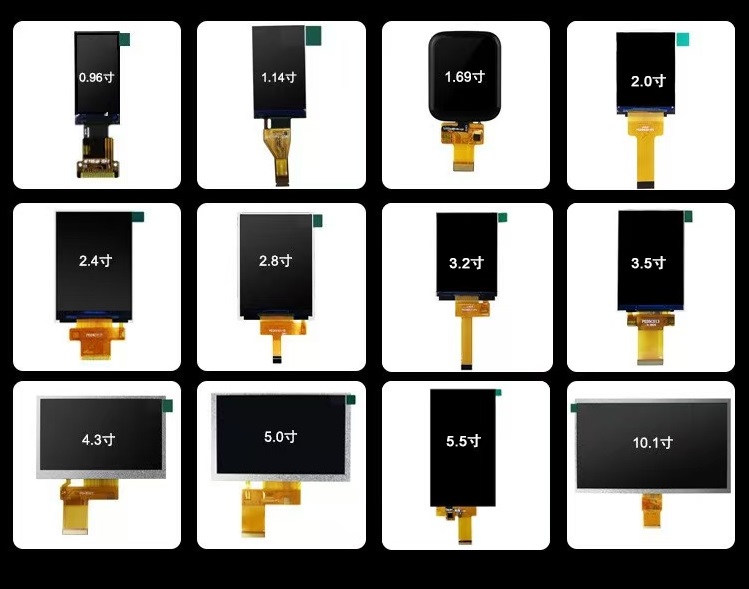

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch