News

LCD Screen White Spots: How to Prevent and Control

LCD Screen White Spots: How to Prevent and Control

LCD Screen White Spots: How to Prevent and Control

Why Pay Attention to LCD Screen White Spots

In industrial equipment, medical devices, smart energy systems, and transportation terminals, the reliability of LCD modules directly affects product delivery and brand reputation.

Even a seemingly minor defect such as an LCD white spot (bright dot) can result in product returns, functional failures, or customer complaints. Eliminating white spots before shipment is therefore essential.

Common Causes of LCD White Spots in Manufacturing

Industry experience shows that white spots typically arise from:

-

Voltage/driver instability: Local bright points appearing during electrical testing.

-

Uneven backlight modules: Creating localized or patchy white spots.

-

Cell defects: Uneven liquid-crystal distribution or alignment-layer issues.

-

ESD damage: Improper handling or testing causing permanent bright dots.

-

Bonding/assembly issues: Air bubbles or contamination during optical bonding leading to visible spots.

These are not random issues and can be effectively controlled through strict quality inspections.

Can LCD White Spots Be Repaired?

-

Repairable: Surface contamination or bonding bubbles → can often be reworked.

-

Non-repairable: Cell defects, backlight problems, or ESD damage → usually require full module replacement.

Whether repair is possible depends on the source of the defect.

How to Prevent White Spot Problems

Manufacturing Measures

-

Improve testing accuracy; add high-voltage and extended aging tests.

-

Enforce strict cleanroom management to reduce contamination.

-

Optimize optical bonding to avoid bubbles and unevenness.

-

Strengthen ESD protection to minimize potential damage.

User Recommendations

-

Avoid long-term exposure to high temperature or humidity.

-

Prevent external pressure on the screen surface.

-

Choose LCD modules that have undergone rigorous testing and reliability validation.

DINGTouch Rigorous Quality Control to Eliminate White Spots

Incoming Quality Control (IQC)

Strict inspection of glass substrates, backlights, ICs, and FPCs to ensure full compliance with specifications.

In-Process Quality Control (IPQC)

Multi-point monitoring during COG/FOG bonding, backlight assembly, and optical bonding to detect and correct defects in real time.

Final Quality Control (FQC)

-

Appearance check: No stains, scratches, or bubbles.

-

Function test: Lighting test to detect bright, dark, or white spots.

-

Performance sampling: Color uniformity, response speed, and brightness stability.

Aging Test

Continuous operation for 2–4 hours under high temperature and humidity to verify stability and filter out potential white spot issues.

Outgoing Quality Control (OQC)

Comprehensive inspection before packaging to ensure only qualified products are shipped.

Customized Testing and Services

Beyond standard testing, DINGTouch provides:

-

Extended electrical testing: Supports special voltages, interfaces, and signal conditions.

-

Customized reliability validation: High/low temperature cycling, vibration, humidity stress, and more.

-

Application-specific shipment standards: Stricter acceptance criteria for medical, energy, and industrial control applications.

Conclusion: Quality Begins with Testing, Differentiation Comes from Control

LCD white spots are a common challenge in the display industry. While many suppliers conduct IQC, IPQC, FQC, and OQC, they often rely heavily on sampling, have insufficient aging tests, and lack customized procedures.

DINGTouch Advantages

-

100% electrical and lighting inspection: Unlike industry sampling, every module is fully tested.

-

Enhanced aging test: Long-term high-temperature and high-humidity operation exposes hidden defects.

-

Customized electrical testing: Supports specific voltages, interfaces, and signal conditions.

-

Application-based shipment standards: Stricter acceptance criteria for medical, energy, and industrial use cases.

-

Complete traceability: Full test records to support audits and certifications.

By choosing DINGTouch, you gain stricter testing, more reliable quality, and controlled delivery.

For more information, contact us at sales@szdingtouch.com.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

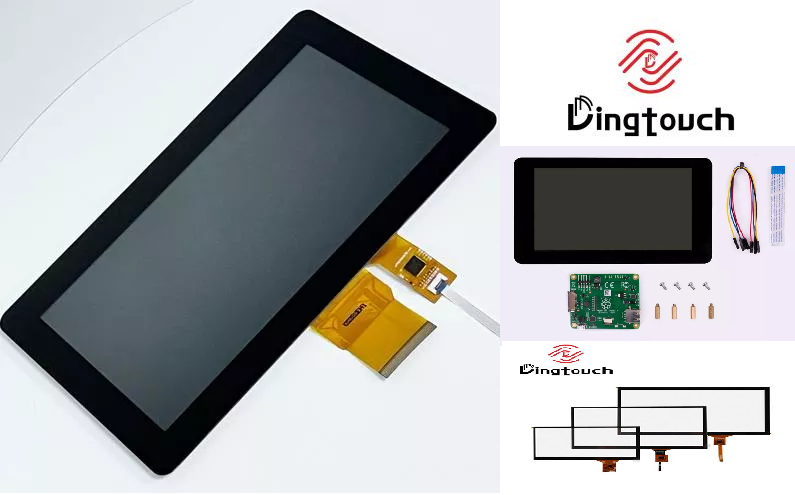

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

#Medicaltouchscreencalibration, #capacitivetouchcalibrationguide, #IEC60601touchscreen, #DINGTouchmedical display, #touchscreenaccuracy, #touchscreen driftfix, #medicalequipmenttouchsolutions, #IP65touchpanel, #IK10medicaltouchscreen, #glove touch medical monitor,#ILITEKTouchControllerICSelectionGuide ,#OCAtoOCR #GT911,#CustomizedWideTemperatureTouchScreenSolutions, #Waterproof Touchscreen

DINGTouch — Custom Touch Display Solutions Expert

Every touch, clear and precise, ready for any environment.

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch