News

Internal Structure Of LCD Panel And Its Analysis

Internal Structure of LCD Panel and Its Analysis

Liquid Crystal Display (LCD) panels are widely used in various applications, from consumer electronics to industrial control systems, due to their thin profile, low power consumption, and excellent visual performance. Understanding the internal structure of an LCD panel is crucial to grasp how these displays function and how design improvements impact image quality, durability, and efficiency.

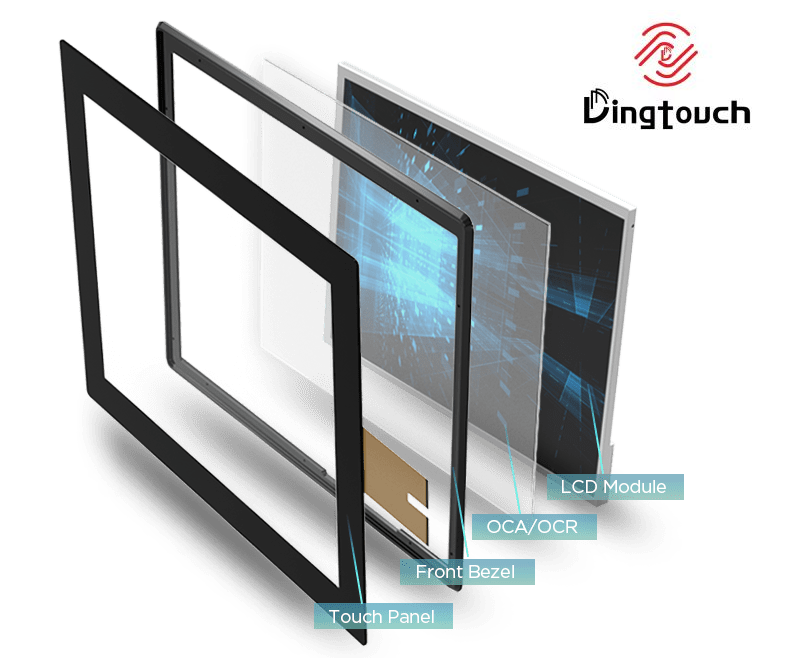

1. Basic Layered Structure of an LCD Panel

An LCD panel consists of multiple precisely arranged layers, each performing a specific function. From front to back, a typical LCD panel includes:

1.1. Polarizer Film (Front Layer)

-

Function: Controls light polarization. The front polarizer allows only light waves oscillating in a certain direction to pass through.

-

Significance: Essential for modulating light with the liquid crystals.

1.2. Glass Substrate (Top Layer)

-

Function: A transparent layer that supports the Thin Film Transistor (TFT) array or Color Filter (CF), depending on the side.

-

Significance: Provides a rigid structure and acts as a base for subsequent layers.

1.3. Color Filter Layer

-

Function: Contains red, green, and blue (RGB) filters to generate color images.

-

Structure: Usually combined with black matrix and overcoat for precision and light control.

-

Significance: Determines color quality and contrast.

1.4. Transparent Electrodes (ITO Layer)

-

Material: Indium Tin Oxide (ITO).

-

Function: Forms the electrodes that apply voltage to the liquid crystal layer.

-

Significance: Transparent and conductive, essential for driving pixels.

1.5. Liquid Crystal Layer

-

Function: The core of the LCD. Liquid crystals align or twist in response to voltage, controlling light passage.

-

Types: TN, IPS, VA — each with different alignment methods and viewing characteristics.

-

Significance: Responsible for image formation by modulating light.

1.6. TFT Array (Active Matrix)

-

Function: Comprises thin-film transistors that individually control each pixel.

-

Significance: Enables high-resolution, fast-switching displays.

1.7. Alignment Layers

-

Function: Ensure the correct orientation of liquid crystals.

-

Process: Typically created by rubbing a polymer surface.

-

Significance: Crucial for consistent visual output and pixel response.

1.8. Spacer Beads

-

Function: Maintain a uniform gap between substrates for even liquid crystal distribution.

-

Significance: Prevents display non-uniformity or light leakage.

1.9. Glass Substrate (Bottom Layer)

-

Function: Houses the TFT array (in most designs) and provides structural support.

1.10. Rear Polarizer

-

Function: Further polarizes light and works in conjunction with the front polarizer.

-

Significance: Key in achieving proper image formation and contrast.

1.11. Backlight Module

-

Components: LED light source, light guide plate (LGP), diffuser, prism films.

-

Function: Supplies the necessary illumination, as LCDs are not self-emissive.

-

Significance: Critical for brightness, uniformity, and visibility.

2. Working Principle Summary

The LCD works on the principle of light modulation through liquid crystals:

-

Without Voltage: Liquid crystals remain aligned, twisting polarized light to pass through both polarizers, making the pixel appear bright.

-

With Voltage: Crystals realign, preventing light from passing through, making the pixel appear dark.

By varying voltage on individual pixels and using color filters, full-color images are formed.

3. Analysis: Design Impacts on Performance

| Design Element | Impact on Performance |

|---|---|

| Liquid Crystal Type | Affects viewing angle, response time, contrast |

| Polarizer Quality | Influences brightness and glare control |

| TFT Design | Determines resolution, power efficiency |

| Backlight Design | Controls brightness, energy usage, heat output |

| Color Filter Accuracy | Affects color fidelity and uniformity |

| Spacer Precision | Maintains display uniformity |

4. Conclusion

The internal structure of an LCD panel is a sophisticated system where optical, electrical, and mechanical components work in harmony. By analyzing each layer, we gain insight into how display quality is achieved and where improvements can be made—whether for sharper visuals, better durability, or energy efficiency. This understanding is vital for engineers, designers, and anyone involved in display technologies.

Whether you're looking for custom LCD sizes, wide temperature support, or optimized high-brightness displays, our expert team at DINGTouch is ready to help.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

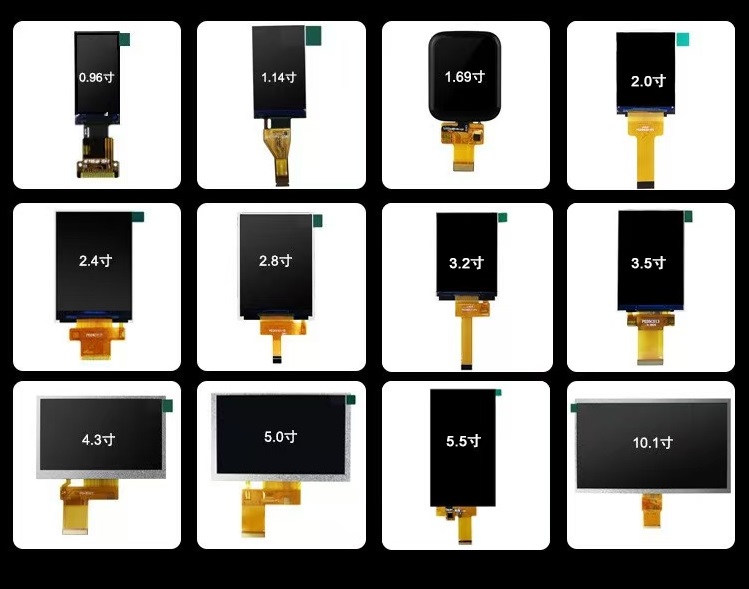

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

Contact our technical specialists today for tailored solutions:

Sales@szdingtouch.com

Find the DINGTouch technical team to achieve the success of your company's new project.

What DINGTOUCH can do:

Dingtouch Industrial Capacitive Touch Screen Manufacturer

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch