News

How To Make A Projected Capacitive Touch Screen?

How To Make A Projected Capacitive Touch Screen?

Content Menu

● Understanding Projected Capacitive Technology

>> Key Components of Projected Capacitive Touch Screens

● Step-by-Step Guide to Making a Projected Capacitive Touch Screen

>> Step 1: Prepare the Touch Panel

>> Step 2: Create the Electrode Grid

>> Step 3: Connect to Microcontroller

>> Step 4: Testing Your Touch Screen

● Enhancements and Applications

● Advantages of Projected Capacitive Touch Screens

● Applications Across Industries

● Future Trends in Projected Capacitive Technology

>> 1. What materials can I use for my capacitive touch screen?

>> 2. How does a capacitive touch screen detect touch?

>> 3. Can I make a multi-touch capacitive screen at home?

>> 4. What microcontrollers are suitable for this project?

>> 5. What software do I need for programming my capacitive touch screen?

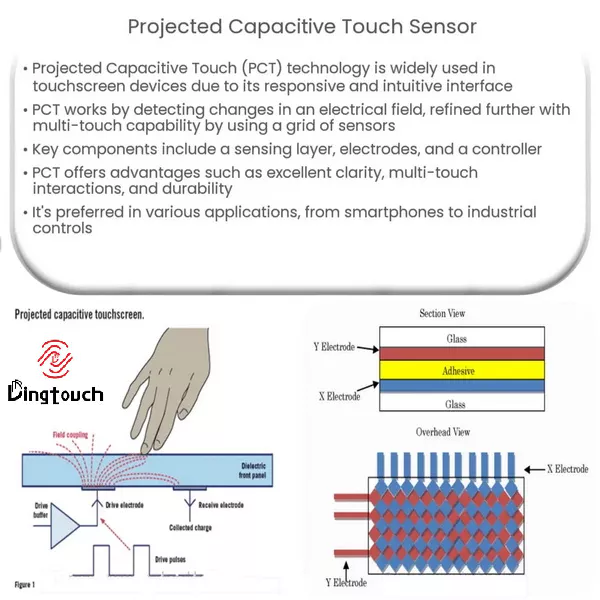

Projected capacitive (PCAP) touch screens have become ubiquitous in modern technology, powering devices from smartphones to tablets and kiosks. This article will guide you through the process of making your own projected capacitive touch screen, detailing the necessary materials, construction steps, and underlying technology.

Understanding Projected Capacitive Technology

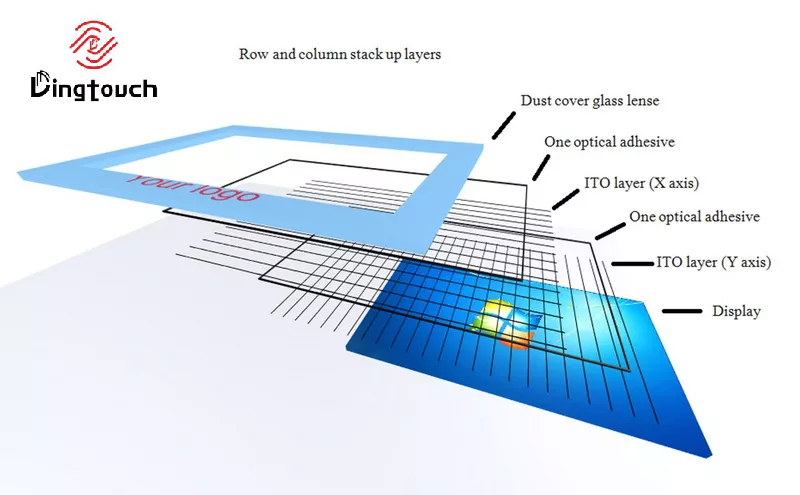

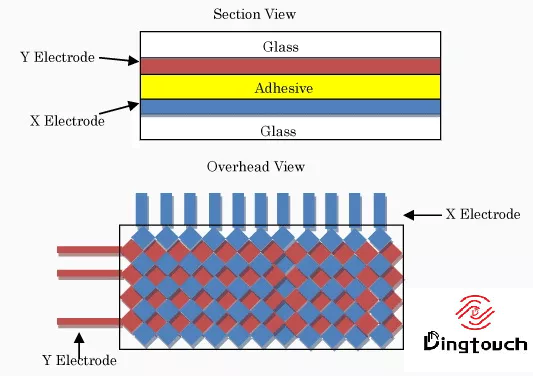

Projected capacitive touch technology operates by measuring changes in capacitance when a conductive object, such as a human finger, approaches the screen. The touch screen consists of a grid of electrodes arranged in rows and columns behind a glass surface. When a finger comes close to the electrodes, it alters the capacitive field, which is detected by the touch controller.

Key Components of Projected Capacitive Touch Screens

- Electrodes: Typically made from transparent conductive materials like Indium Tin Oxide (ITO), these electrodes form a grid pattern.

- Glass Surface: Acts as a protective layer while allowing light to pass through for display purposes.

- Touch Controller: This component processes the changes in capacitance and determines the location of the touch.

- Microcontroller: Used for interfacing with the touch controller and processing touch inputs.

Materials Needed

To create a projected capacitive touch screen, gather the following materials:

- Conductive Material: Indium Tin Oxide (ITO) film or conductive copper tape.

- Glass Panel: A piece of glass or acrylic to act as the surface.

- Microcontroller: An Arduino or Raspberry Pi for processing inputs.

- Wires: For connections between components.

- Breadboard: For prototyping your circuit.

- Power Supply: To power your microcontroller and sensors.

Step-by-Step Guide to Making a Projected Capacitive Touch Screen

Step 1: Prepare the Touch Panel

1. Cut Your Glass Panel: Decide on the size of your touch panel and cut your glass or acrylic accordingly.

2. Clean the Surface: Ensure that the glass is free from dust and fingerprints to avoid interference with touch detection.

Step 2: Create the Electrode Grid

1. Design Your Sensor Layout: Plan a grid layout for your electrodes. A simple 4x4 grid is ideal for beginners.

2. Cut Conductive Material: If using ITO film, cut it into strips that will serve as electrodes. If using copper tape, cut it into small squares or circles.

3. Attach Electrodes to Glass: Securely attach the conductive material to one side of your glass panel using adhesive.

Step 3: Connect to Microcontroller

1. Wire Connections: Connect wires from each electrode to the analog pins on your microcontroller.

2. Add Resistors: Connect a resistor (typically 10 Megaohm) from each electrode to ground to stabilize readings.

3. Microcontroller Setup: Program your microcontroller using Arduino IDE or similar software to read inputs from the electrodes.

Step 4: Testing Your Touch Screen

1. Upload Code: Upload your code to the microcontroller and ensure that it is set up to read changes in capacitance.

2. Test Touch Detection: Gently touch different areas of the screen to test responsiveness. Adjust sensitivity settings in your code if necessary.

Enhancements and Applications

Once you have built your projected capacitive touch screen, consider these enhancements:

- Multi-Touch Capability: Modify your design to support multiple simultaneous touches by expanding your grid layout and programming logic.

- Environmental Protection: Use additional layers of glass or plastic for durability against scratches and environmental factors.

- Integration with Other Technologies: Combine your touch screen with other sensors or IoT devices for advanced applications like smart home controls or interactive displays.

Advantages of Projected Capacitive Touch Screens

Projected capacitive touch screens offer several advantages over other types of touch screens:

- High Sensitivity and Accuracy: The advanced sensing technology employed in projected capacitive touch screens enables high sensitivity and accuracy, resulting in a more responsive and precise touch experience.

- Durability: With rugged construction and scratch-resistant cover glass, projected capacitive touch screens are highly durable and suitable for demanding environments.

- Optical Clarity: The use of transparent materials such as glass ensures excellent optical clarity and visibility, even in bright lighting conditions.

- Versatility: Projected capacitive touch screens are compatible with various input methods, including fingers, styluses, and gloved hands, making them suitable for a wide range of applications.

Applications Across Industries

The versatility of projected capacitive touch screens has led to their adoption across various industries:

- Consumer Electronics: Smartphones, tablets, laptops, and wearable devices leverage projected capacitive touch screens to deliver intuitive and engaging user interfaces.

- Retail and Hospitality: Interactive kiosks, self-service terminals, and digital signage enhance customer engagement and streamline operations in retail stores, restaurants, and hotels.

- Industrial Automation: HMI (Human-Machine Interface) panels, control systems, and industrial displays utilize projected capacitive touch screens for efficient monitoring and control of machinery and processes.

- Medical Devices: Medical-grade touch screens enable healthcare professionals to access patient records, diagnostic images, and medical applications with ease and accuracy.

- Gaming and Entertainment: Gaming consoles, arcade machines, and interactive exhibits leverage projected capacitive touch screens to deliver immersive gaming and entertainment experiences.

Future Trends in Projected Capacitive Technology

As technology continues to advance, projected capacitive touch screens are poised to evolve further:

- Flexible and Curved Displays: Flexible designs allow manufacturers to create innovative form factors for smartphones, wearables, and automotive displays.

- Integration with AI and IoT: Combining PCAP technology with artificial intelligence (AI) enables smarter devices capable of learning user preferences for enhanced interaction.

- Enhanced Sensing Capabilities: Advances in sensing technology may include force sensing and haptic feedback for a more tactile user experience.

- Gesture Recognition Technologies: These technologies enable users to interact with screens through gestures rather than direct contact—ideal for maintaining hygiene in public spaces.

Conclusion

Creating a projected capacitive touch screen is an exciting project that not only enhances your understanding of electronics but also opens doors to innovative applications in technology. With basic materials and some coding skills, you can build a functional touch interface suitable for various applications. As you gain experience, feel free to explore more advanced features and integrations that can enhance your projects further.

The rise of projected capacitive touchscreen technology has revolutionized how we interact with our devices. From smartphones to tablets, ATM, industrial control systems, PCAP technology has made our interactions more intuitive and efficient. Its unique advantages have made it popular across various applications. As we look ahead into the future of technology integration within our daily lives, projected capacitive touchscreen systems will play an increasingly central role in shaping our digital experiences.

Related Questions

1. What materials can I use for my capacitive touch screen?

You can use Indium Tin Oxide (ITO) film or conductive copper tape as conductive materials along with glass or acrylic as an insulating surface.

2. How does a capacitive touch screen detect touch?

Capacitive touch screens detect touch by sensing changes in electrostatic fields caused by conductive objects like human fingers approaching or touching their surface.

3. Can I make a multi-touch capacitive screen at home?

Yes! By using multiple sensors connected to different pins on your microcontroller, you can create a multi-touch capable interface.

4. What microcontrollers are suitable for this project?

Popular choices include Arduino boards (like Arduino Uno or Nano) due to their ease of use and extensive community support.

5. What software do I need for programming my capacitive touch screen?

You will need Arduino IDE or similar software compatible with your chosen microcontroller for coding and uploading sketches.

By following these steps and understanding how projected capacitive technology works, you can create your own interactive devices while exploring further innovations in this exciting field!

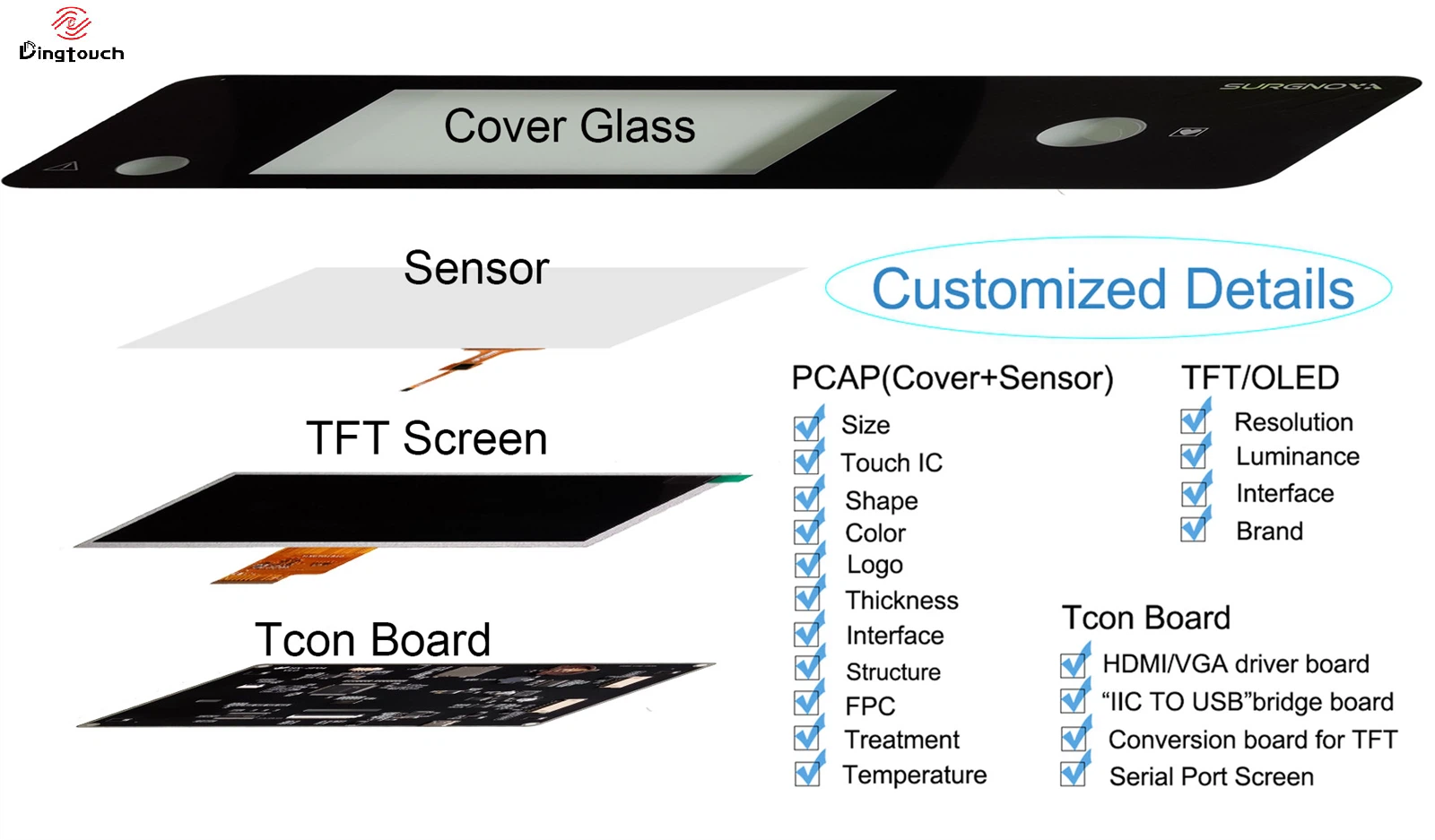

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch