News

How To Fix Pressure Spots on Lcd Screen?

How To Fix Pressure Spots on Lcd Screen?

Content Menu

● Understanding Pressure Spots

>> Common Causes of Pressure Spots

>> 1. Gently Massage the Affected Area

>> 3. Use Specialized Screen Repair Tools

>> 4. Professional Repair Services

● Why Are TFT LCD Screen Prone to Pressure Spots?

● Effective Techniques for Removing Pressure Spots on LCD Screen

● Step-by-Step Guide for Fixing Pressure Spots

>> 3. Warm Micro-Fiber Cloth Method:

● Frequently Asked Questions (FAQs)

>> 1. Can all pressure spots be fixed?

>> 2. Is it safe to use heat on my LCD screen?

>> 3. How do I know if my LCD screen is beyond repair?

>> 4. What should I avoid when trying to fix pressure spots?

>> 5. Can I prevent pressure spots from occurring?

Pressure spots on LCD screen can be a significant annoyance, affecting the visual quality of your device. These spots often manifest as discolored or dark areas on the display, caused by physical pressure applied to the screen. Whether from dropping your device, pressing too hard while cleaning, or placing heavy objects on it, pressure spots can disrupt your viewing experience. Fortunately, there are methods to address this issue effectively. This article will delve into the causes of pressure spots, various DIY repair techniques, and preventive measures to keep your LCD screen in pristine condition.

Understanding Pressure Spots

What Are Pressure Spots?

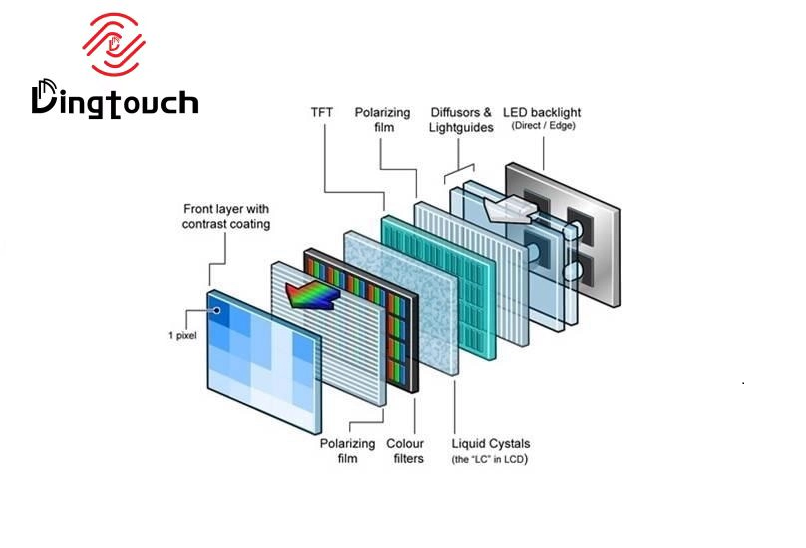

Pressure spots, also known as pressure marks or pressure points, occur when excessive force is applied to the delicate layers of an LCD screen. The liquid crystals within the display can become misaligned or damaged due to this pressure, resulting in visible blemishes that can be distracting during use.

Common Causes of Pressure Spots

- Accidental Drops: Dropping your device can cause immediate pressure damage to the screen.

- Excessive Pressure: Pressing too hard on the screen while using a stylus or cleaning it can lead to pressure spots.

- Heavy Objects: Leaving heavy items on top of the screen for extended periods can create pressure marks.

How To Fix Pressure Spots

1. Gently Massage the Affected Area

One of the simplest methods to fix pressure spots is to gently massage the affected area:

- Turn Off the Device: Always start by turning off your device to avoid further damage.

- Use a Soft Cloth: Take a soft microfiber cloth and gently rub the affected area in a circular motion. This technique helps redistribute the liquid crystals back into their original position.

- Repeat as Necessary: You may need to repeat this process several times for optimal results.

2. Apply Gentle Heat

Applying heat can sometimes help alleviate pressure spots:

- Hairdryer Method: Set a hairdryer to its lowest setting and hold it about 8-10 inches away from the screen. Warm the affected area gently for a few seconds.

- Massage Again: After applying heat, use a microfiber cloth to massage the area again. Be cautious not to overheat the screen as this could cause further damage.

3. Use Specialized Screen Repair Tools

There are tools specifically designed for fixing LCD screen:

- Screen Repair Kits: These kits often include tools that apply controlled pressure and heat to repair minor issues like dead pixels and pressure spots.

- Follow Instructions Carefully: Ensure you follow any instructions provided with these tools for best results.

4. Professional Repair Services

If DIY methods do not yield satisfactory results:

- Consult Professionals: It may be time to seek professional help from electronics repair shops that specialize in LCD screen. They have access to advanced tools and techniques that can effectively address severe pressure spots without causing additional damage.

Preventing Pressure Spots

1. Use a Screen Protector

Investing in a high-quality screen protector can help distribute force evenly across the surface of your screen, reducing the likelihood of pressure spots forming.

2. Handle with Care

Be mindful when handling your device:

- Avoid Excessive Pressure: Whether cleaning or using your device, avoid pressing too hard on the screen.

- Store Properly: When not in use, store devices in protective cases to shield them from accidental drops or pressure from other objects.

3. Regular Maintenance

Regularly clean your screen with appropriate materials:

- Microfiber Cloths: Use soft microfiber cloths for cleaning to avoid scratching or damaging the surface of your screen.

Why Are TFT LCD Screens Prone to Pressure Spots?

TFT LCD screen are popular for their sharp image quality and precise control over individual pixels. However, their thin structure makes them more prone to damage from pressure. Each pixel in a TFT LCD screen contains its own transistor, which can become misaligned if pressure is applied unevenly. This vulnerability underscores the importance of careful handling and maintenance of devices equipped with this type of display technology.

Effective Techniques for Removing Pressure Spots on LCD Screen

LCD screen have become an integral part of our daily lives, from smartphones and laptops to televisions and computer monitors. However, one common issue that many users face is the appearance of pressure spots on their LCD screen. These pressure spots can appear brighter or darker than the rest of the display and significantly affect viewing experience and reduce overall quality.

Step-by-Step Guide for Fixing Pressure Spots

1. Identify the Cause:

- Determine if pressure spots are due to physical force or manufacturing defects.

- If caused by physical pressure, proceed with gentle massage techniques.

2. Gentle Rubbing Method:

- Turn off your device.

- Use a clean microfiber cloth and gently rub in circular motions over the affected area.

- Apply minimal pressure; excessive force may worsen damage.

3. Warm Micro-Fiber Cloth Method:

- Dampen a microfiber cloth with distilled water (avoid excessive moisture).

- Gently rub around the spot; warmth helps loosen any particles causing visibility issues.

4. Suction Cup Technique:

- Place a suction cup over the spot and gently pull it away from the screen.

- This method helps redistribute liquid crystals but requires caution to avoid further damage.

5. Use Cleaning Solutions:

- If dirt contributes to visibility issues, use specialized cleaning solutions formulated for screens.

- Follow instructions carefully; avoid harsh chemicals that may damage displays.

6. Pixel-Fixing Software:

- Some software applications cycle through colors rapidly which may help unstick pixels.

- Use such programs cautiously as they may cause further damage if misused.

Conclusion

Pressure spots on LCD screen can be frustrating but are often manageable with proper techniques and preventive measures. By understanding how these spots form and implementing effective repair methods, you can restore your screen's clarity and functionality. Remember always to handle your devices with care and consider professional assistance if DIY methods do not resolve the issue effectively.

Frequently Asked Questions (FAQs)

1. Can all pressure spots be fixed?

Not all pressure spots are fixable; some may require complete screen replacement if they are severe or caused by internal damage.

2. Is it safe to use heat on my LCD screen?

Applying gentle heat can help in some cases, but be cautious not to overheat as it may cause further damage.

3. How do I know if my LCD screen is beyond repair?

If you notice persistent dead pixels or discoloration that does not improve with DIY methods, it may be time for professional evaluation.

4. What should I avoid when trying to fix pressure spots?

Avoid using excessive force or abrasive materials which could worsen the damage rather than fixing it.

5. Can I prevent pressure spots from occurring?

Yes, using screen protectors, handling devices carefully, and avoiding placing heavy objects on screens can help prevent pressure spots from forming.

By following these guidelines and taking proactive measures, you can maintain a clear and functional display on your LCD devices for years to come!

DINGTouch: Bringing Innovation from Concept to Reality

DINGTouch is committed to turning your product ideas into reality by providing customized touch display solutions ranging from 2.8” to 65”. With expertise in G+G and G+F+F structures, high brightness, multi-touch, and protective designs, we offer multi-interface support (I2C, USB, SPI, RS485, UART, etc.).

With extensive industry experience and successful case studies, DINGTouch has provided high-quality custom solutions for industrial control, smart homes, medical devices, commercial display, and automotive applications.

For personalized custom solutions, differentiated designs, or special specifications, please contact our technical team at

![]() sales@szdingtouch.com.

sales@szdingtouch.com.

DINGTouch—Turning Innovation into Reality, Empowering Your Every Creative Idea.

Ready to Build Your Outdoor Display Solution?

Get in touch with us at sales@szdingtouch.com. Our expert engineers will help you design a cost-effective, tailored solution to meet your project’s exact specifications.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

DINGTouch :Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

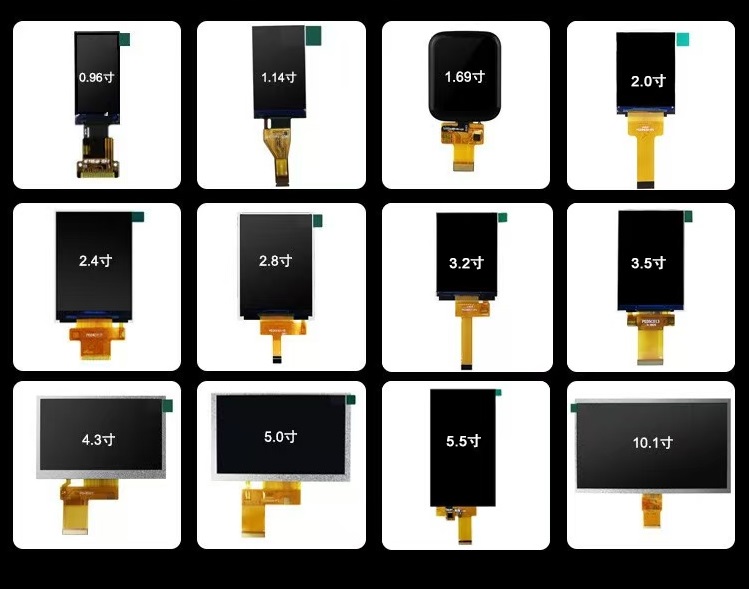

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch