News

How An Lcd Screen Is Made?

How An Lcd Screen Is Made?

Content Menu

● 1. Introduction to LCD Technology

● 2. The Manufacturing Process

>> 2.2 Thin Film Transistor (TFT) Fabrication

>> 2.3 Color Filter Fabrication

>> 2.4 Liquid Crystal Alignment

>> 2.5 Liquid Crystal Injection and Sealing

● 3. Advanced Technologies in LCD Manufacturing

● 4. Innovations in Display Technology

● 5. The Environmental Impact of LCD Manufacturing

>> 1. What materials are used in making an LCD screen?

>> 2. How does an LCD screen produce colors?

>> 3. What is the role of backlighting in an LCD?

>> 4. Why is testing important in LCD manufacturing?

>> 5. What advancements are being made in LCD technology?

Liquid Crystal Display (LCD) have become an integral part of modern technology, used in everything from smartphones to televisions. Understanding how these screen are made involves a fascinating journey through a series of complex processes that transform raw materials into the vibrant displays we rely on daily. This article will explore the intricate steps involved in the manufacturing of LCD screen, providing insights into the technology and precision required at each stage.

1. Introduction to LCD Technology

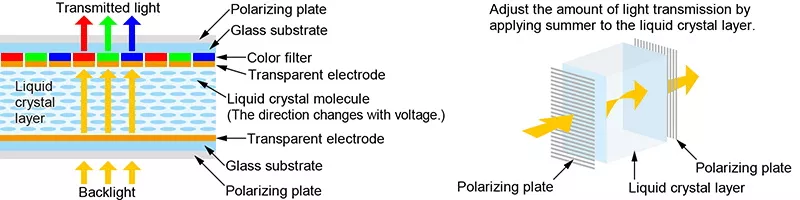

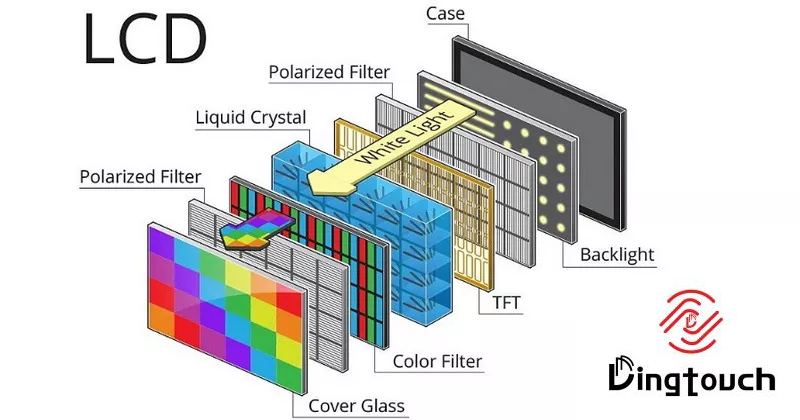

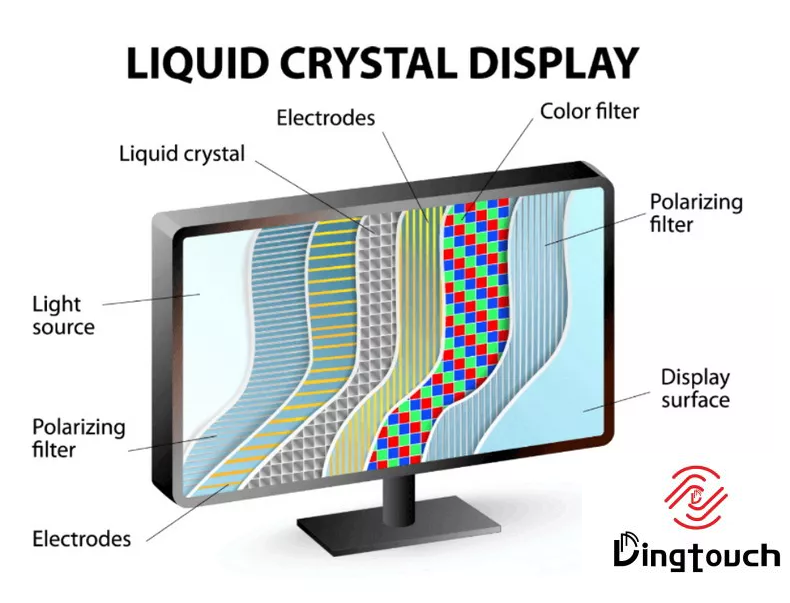

LCD technology utilizes liquid crystals to modulate light, creating images on screen. The fundamental components of an LCD include:

- Backlight: This provides illumination since liquid crystals do not emit light on their own.

- Liquid Crystal Layer: This layer contains liquid crystals that change orientation when an electric field is applied, controlling light passage.

- Color Filters: These filters allow only specific wavelengths of light to pass through, enabling color display.

- Polarizers: These layers filter light to enhance contrast and color accuracy.

The combination of these elements allows LCD to produce sharp, colorful images.

2. The Manufacturing Process

The manufacturing process of LCD screen can be broken down into several key stages:

2.1 Substrate Preparation

The process begins with the preparation of glass substrates. Typically, two glass plates are used: the array substrate and the color filter substrate. These substrates undergo rigorous cleaning processes to remove any impurities or contaminants that could affect the display quality.

2.2 Thin Film Transistor (TFT) Fabrication

The array substrate is coated with a transparent conductive material, usually indium tin oxide (ITO). A layer of amorphous silicon (a-Si) is then deposited using techniques like chemical vapor deposition (CVD). The a-Si layer is patterned to form thin film transistors (TFT), which act as electronic switches controlling each pixel on the LCD screen.

2.3 Color Filter Fabrication

The color filter substrate is coated with a black matrix that defines the boundaries of each pixel. Red, green, and blue color filters are applied using photolithography, where photosensitive material is selectively exposed to light and developed to create the desired patterns.

2.4 Liquid Crystal Alignment

Both substrates undergo a liquid crystal alignment process. A layer of polyimide is applied and rubbed in a specific direction to align the liquid crystal molecules properly. This step is crucial for achieving optimal display functionality.

2.5 Liquid Crystal Injection and Sealing

The array substrate and color filter substrate are aligned facing each other with a narrow gap between them. Liquid crystal material is injected into this gap and sealed using a sealant that prevents leakage.

2.6 Polarizer Attachment

Polarizers are attached to the outer surfaces of the LCD screen to control light polarization. These polarizers are essential for ensuring that only properly oriented light passes through the liquid crystal layer.

2.7 Backlighting

For LCD requiring backlighting, a module consisting of LED or cold cathode fluorescent lamps (CCFL) is attached behind the LCD panel, providing necessary illumination.

*Illustration: Backlight assembly in an LCD screen.*

2.8 Testing and Inspection

After assembly, rigorous testing and inspection are performed to ensure quality and reliability. This includes checks for defects, uniformity, color accuracy, and functionality.

3. Advanced Technologies in LCD Manufacturing

Recent advancements in LCD technology have led to improvements in color accuracy, brightness, and energy efficiency:

- Quantum Dots: Enhance color accuracy by utilizing semiconductor particles that emit specific wavelengths when illuminated.

- Local Dimming: Involves thousands of tiny LEDs for better control over brightness levels across different areas of the screen.

- High Dynamic Range (HDR): Improves contrast ratios significantly by allowing displays to show more detail in both bright highlights and dark shadows.

These innovations help push LCD technology closer to OLED performance while maintaining cost-effectiveness.

4. Innovations in Display Technology

As technology continues to evolve, several innovations are shaping the future of LCD display:

4.1 Mini-LED Backlighting

Mini-LED technology uses thousands of tiny LEDs for backlighting instead of traditional CCFL or larger LEDs. This advancement allows for better control over brightness and contrast levels across the screen, resulting in deeper blacks and brighter whites without increasing power consumption significantly.

4.2 Quantum Dot Technology

Quantum dots are nanometer-sized semiconductor particles that can emit specific colors when illuminated by a light source. Integrating quantum dots into LCD enhances color reproduction and brightness, making images appear more vibrant and lifelike compared to standard displays.

4.3 Flexible Display

Recent developments have led to flexible LCD that can bend without breaking. This innovation opens up new possibilities for wearable devices and foldable smartphones, allowing manufacturers to create more versatile products that cater to consumer needs.

5. The Environmental Impact of LCD Manufacturing

With growing concerns about environmental sustainability, many manufacturers are exploring ways to make LCD production more eco-friendly:

- Sustainable Materials: Companies are increasingly using recyclable materials in their displays and reducing waste during production processes.

- Energy Efficiency: New manufacturing techniques focus on reducing energy consumption during production while improving the energy efficiency of finished products.

These initiatives not only help reduce environmental impact but also appeal to eco-conscious consumers looking for sustainable technology options.

Conclusion

The manufacturing process of LCD screen is a complex interplay of various technologies and precise engineering techniques. From substrate preparation to final testing, each step requires meticulous attention to detail to produce high-quality displays that meet consumer demands. As technology continues to advance, we can expect further enhancements in display quality and efficiency, making LCD an enduring choice in various applications from consumer electronics to industrial use.

Frequently Asked Questions

1. What materials are used in making an LCD screen?

LCD screen primarily use glass substrates, liquid crystals, polarizers, indium tin oxide (ITO), and various color filters.

2. How does an LCD screen produce colors?

Colors are produced by combining red, green, and blue subpixels controlled by TFTs that adjust light intensity based on electric signals.

3. What is the role of backlighting in an LCD?

Backlighting provides illumination for the screen since liquid crystals do not emit light on their own; it enhances visibility in various lighting conditions.

4. Why is testing important in LCD manufacturing?

Testing ensures that each screen meets quality standards for defects, uniformity, color accuracy, and functionality before being shipped to consumers.

5. What advancements are being made in LCD technology?

Recent advancements include quantum dots for better color accuracy, local dimming for enhanced brightness control, and HDR for improved contrast ratios.

This comprehensive overview provides insights into how LCD screen are made while addressing common questions related to their manufacturing process and technological advancements.

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

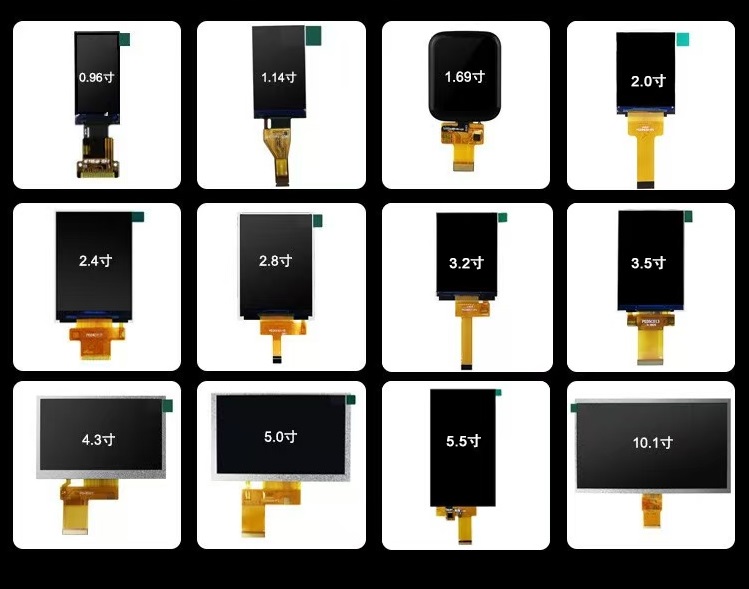

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch