News

How 8-wire Resistive Touch Screen Works?

How 8-wire Resistive Touch Screen Works?

Content Menu

● What is an 8-Wire Resistive Touch Screen?

>> Structure

● Advantages of 8-Wire Resistive Touch Screen

● Comparison with Other touchscreen Technologies

● Future Trends in touchscreen Technology

>> 1. What are the main differences between 4-wire and 8-wire resistive touch screen?

>> 2. Can 8-wire resistive touch screens support multi-touch?

>> 3. How do you calibrate an 8-wire resistive touchscreen?

>> 4. Are there any disadvantages to using an 8-wire resistive touchscreen?

>> 5. What industries commonly use 8-wire resistive touchscreen?

Resistive touch screen have become a fundamental component in various electronic devices, ranging from smartphones to industrial control panels. Among the different types of resistive touch screens, the 8-wire resistive touchscreen stands out due to its enhanced accuracy and stability. This article will delve into the workings of 8-wire resistive touch screens, their advantages, applications, and more.

What is an 8-Wire Resistive Touch Screen?

An 8-wire resistive touch screen is an advanced version of the traditional 4-wire resistive touch screen. The primary difference lies in the addition of four extra wires that enhance the device's ability to detect touch accurately.

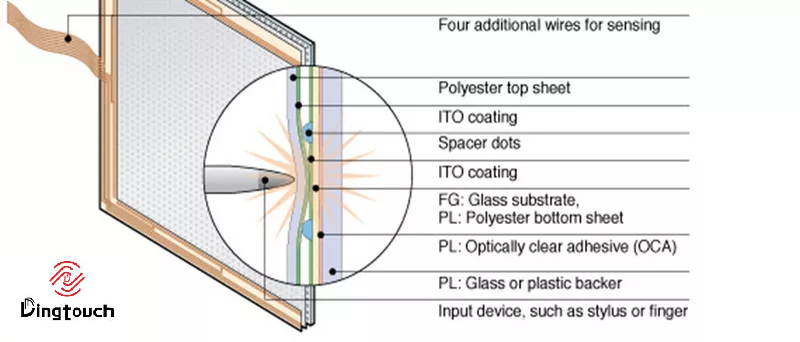

Structure

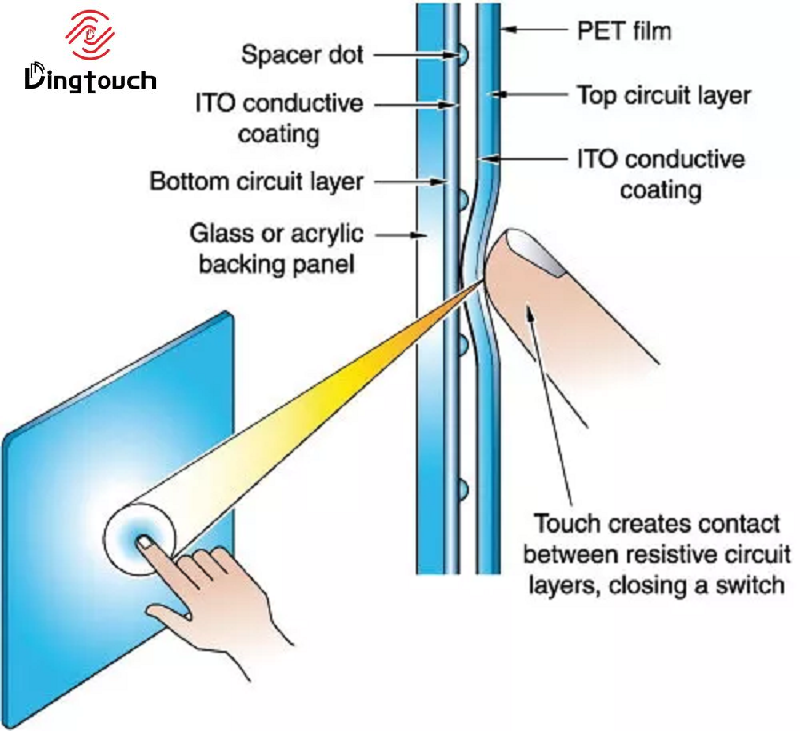

The structure of an 8-wire resistive touchscreen consists of two flexible layers coated with a resistive material. These layers are separated by tiny spacer dots that maintain a small gap when not in use. The two layers are:

- Top Layer: This layer is typically made from a flexible plastic material (like PET) and is designed to deform under pressure.

- Bottom Layer: Usually made from rigid glass or hard plastic, this layer contains a resistive coating that registers touch points when the top layer is pressed against it.

The additional four wires in an 8-wire system are used to sense the voltage applied at the edges of the touch screen, which compensates for offset errors and enhances accuracy.

How Does It Work?

The operation of an 8-wire resistive touchscreen can be broken down into several key steps:

1. Pressure Application: When a user presses down on the top layer, it deforms and makes contact with the bottom layer.

2. Resistance Change: The contact between the two layers creates a change in electrical resistance at that specific point.

3. Coordinate Calculation: The touchscreen controller detects this change and calculates the exact coordinates (X and Y) of the touch based on voltage measurements across both layers.

4. Signal Processing: The controller then sends this information to the device's processor to execute the corresponding action, such as opening an application or selecting an item.

Advantages of 8-Wire Resistive Touch Screens

8-wire resistive touchscreens offer several benefits over their 4-wire counterparts:

- Increased Accuracy: The additional wires allow for more precise detection of touch points, making these screens ideal for applications requiring high precision.

- Stability: With more conductive tracers than 4- and 5-wire screens, 8-wire devices are less likely to experience phantom touches or other stability issues.

- Stylus Support: Unlike capacitive screens, which typically require direct contact with a finger, resistive screens can be operated using a stylus or any pointed object.

- Durability Against Contaminants: They are more resistant to dust and moisture compared to capacitive screens, making them suitable for various environments.

Applications

Due to their unique advantages, 8-wire resistive touchscreens are commonly used in:

- Industrial Control Systems: Their durability and precision make them ideal for machinery control panels.

- Medical Devices: Used in devices where cleanliness and reliability are crucial.

- Point-of-Sale Terminals: Their ability to work with gloves or styluses makes them suitable for retail environments.

Detailed Working Mechanism

To further understand how an 8-wire resistive touchscreen operates, let's explore its detailed working mechanism:

Voltage Application

In an 8-wire resistive touchscreen, each layer has electrodes that run along its edges. When a voltage is applied across one layer (say, the X-axis), it creates an electric field across that layer. The second layer (Y-axis) measures this voltage change when pressure is applied at a specific point on the screen.

Measurement Process

The additional four wires serve as sense wires connected to each electrode. These sense wires measure the voltage at each electrode during operation. When a user touches the screen:

- The top layer flexes downward due to pressure.

- This flexing causes it to make contact with the bottom layer at one specific point.

The controller measures how much voltage has changed at each electrode due to this contact. By comparing these values against pre-set thresholds, it can accurately determine where on the screen the user has touched.

Calibration Benefits

One significant advantage of using an 8-wire system is that it reduces or even eliminates the need for regular calibration. Traditional systems often required recalibration over time as wear and tear affected their accuracy. However, because the additional wires continuously measure voltage changes at each electrode, they can automatically adjust for any discrepancies in alignment or resistance over time.

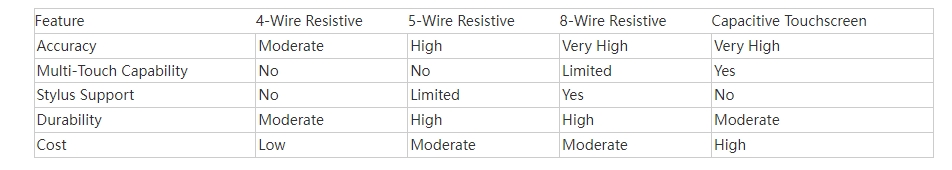

Comparison with Other touchscreen Technologies

To better appreciate the unique features of 8-wire resistive touchscreens, it's essential to compare them with other technologies:

From this comparison table, it's clear that while capacitive screens excel in sensitivity and multi-touch capabilities, 8-wire resistive screens offer unique advantages in terms of durability and usability with various input methods.

Future Trends in touchscreen Technology

As technology continues to evolve, we can expect several trends impacting touchscreen technology:

- Integration with AI: Future touchscreen interfaces may incorporate artificial intelligence for predictive gestures and improved user interaction.

- Enhanced Durability Materials: Advances in materials science may lead to even more durable touchscreen surfaces resistant to scratches and environmental damage.

- Hybrid Technologies: We may see hybrid systems combining capacitive and resistive technologies to leverage the strengths of both systems while minimizing their weaknesses.

Conclusion

In summary, 8-wire resistive touchscreens represent a significant advancement over traditional resistive technologies. Their enhanced accuracy and stability make them suitable for various applications where precision is critical. As technology continues to evolve, these touchscreens will likely remain an essential component in many electronic devices due to their versatility and robustness.

Related Questions

1. What are the main differences between 4-wire and 8-wire resistive touch screen?

The primary difference lies in the number of wires used for sensing. While 4-wire systems use four wires for power and sensing, 8-wire systems add four additional wires for improved accuracy and reduced calibration needs.

2. Can 8-wire resistive touch screen support multi-touch?

Generally, traditional resistive touchscreen, including 8-wire models, support single-touch input only. However, some advanced designs may incorporate limited multi-touch capabilities depending on specific configurations.

3. How do you calibrate an 8-wire resistive touchscreen?

Calibration is often automatic in 8-wire systems due to their additional sensing capabilities that account for voltage changes at electrodes. This reduces the need for regular recalibration compared to older technologies.

4. Are there any disadvantages to using an 8-wire resistive touchscreen?

While they offer numerous advantages, drawbacks include lower sensitivity compared to capacitive screens and vulnerability to scratches over time due to their flexible layers.

5. What industries commonly use 8-wire resistive touchscreen?

Industries such as healthcare, manufacturing, retail (POS systems), automotive displays frequently utilize these screens due to their durability and versatility in various environments.

DINGTouch: Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch