News

FOG Production Process: A Comprehensive Guide by DINGTouch

FOG Production Process: A Comprehensive Guide by DINGTouch

In the ever-evolving world of touch screen technology, DINGTouch stands out as a leader in providing cutting-edge solutions for various industries. One of the critical processes in our touch screen manufacturing is the FOG (FPC on Glass) production process, a technique that ensures the seamless integration of flexible printed circuits (FPC) with LCD glass. This article delves into the FOG process, highlighting its significance, the meticulous steps involved, and the stringent quality control measures that set DINGTouch apart from competitors.

What is the FOG Production Process?

The FOG (FPC on Glass) production process is a sophisticated technique that involves the mechanical and electrical bonding of liquid crystal display (LCD) glass with flexible printed circuits (FPC) using Anisotropic Conductive Film (ACF). This process is crucial in ensuring the functionality and reliability of touch screens used in various applications, from industrial controls to smart home devices.

Step-by-Step Breakdown of the FOG Process

At DINGTouch, the FOG production process is carried out with precision and care, adhering to the highest industry standards. The process involves the following key steps:

-

ACF Pre-Attachment

The process begins with the pre-attachment of ACF to the LCD glass or FPC. Using precise temperature and pressure settings, the ACF is applied to the specific areas where the bonding will occur. The accuracy of this step is crucial, as it ensures that the ACF is applied with the correct length and position, maintaining a flat surface free of bubbles. -

Pre-Bonding

Next, the FPC and LCD are aligned using advanced image processing systems. This alignment must be incredibly precise, as the pitch between the lines is often as small as 0.05 mm, requiring alignment accuracy within ±0.005 mm. Once aligned, the pre-bonding process creates an initial connection between the FPC and LCD. -

Main Bonding

The main bonding step involves subjecting the pre-bonded assembly to higher temperatures and pressures. This causes the conductive particles in the ACF to deform and break through the insulation layer, creating a reliable electrical connection between the FPC and LCD glass. Simultaneously, the ACF adhesive hardens, providing mechanical strength to the bond. -

Quality Inspection

The final step in the FOG process is a thorough inspection of the bonded product. At DINGTouch, we utilize electron microscopes with magnification up to 500 times to inspect the bonds, ensuring that each product meets our stringent quality standards.

Key Technologies in FOG Production

Ensuring the highest quality in FOG production requires advanced technology and meticulous attention to detail. At DINGTouch, we focus on three critical aspects:

-

Pressure Control

The bonding pressure directly influences the quality of the connection between the FPC and LCD. Too much pressure can crush the conductive particles in the ACF, leading to electrical failure, while too little pressure may result in an inadequate bond. DINGTouch’s state-of-the-art equipment allows for precise pressure control, ensuring optimal results. -

Temperature Management

The curing of the ACF adhesive depends on the rate of temperature increase and the peak temperature achieved. At DINGTouch, we carefully control these parameters to ensure that the bond is strong and the surface quality is maintained, avoiding defects such as bubbles or pinholes. -

Flatness of the Bonding Head

The flatness of the bonding head is crucial in the FOG process. An uneven bonding head can cause uneven pressure distribution, leading to issues such as incomplete bonding or the formation of bubbles within the ACF. DINGTouch’s equipment undergoes regular calibration and maintenance to ensure the flatness and alignment of the bonding head, preventing these issues and ensuring high-quality bonds.

DINGTouch’s Commitment to Excellence

As an industry leader, DINGTouch is committed to pushing the boundaries of touch screen technology. Our FOG production process is a testament to our dedication to quality and innovation. By leveraging the latest technologies and adhering to strict quality control measures, we ensure that our touch screen products are not only reliable but also tailored to meet the specific needs of our customers.

Applications and Benefits

The touch screens produced through DINGTouch’s FOG process are used in a wide range of applications, including industrial control systems, medical devices, smart home interfaces, and security systems. The precision and reliability of our FOG process ensure that these touch screens perform flawlessly, even in demanding environments.

Conclusion

In conclusion, DINGTouch’s FOG production process is a critical component of our touch screen manufacturing, enabling us to deliver high-quality, reliable products to our customers. Our focus on precision, advanced technology, and strict quality control sets us apart as a leader in the industry, ensuring that we continue to meet and exceed the expectations of our clients across various sectors.

DINGTouch:Committed to continuous innovation and improvement of product quality to meet customers' high requirements and expectations.

DINGTouch is a manufacturer that provides high quality touch screen panels. Focus on the design, manufacturing and sales of touch screen panels, and are committed to providing customized solutions that satisfy customers.

DINGTouch: In the process of customizing touch screen panels, we focus on close cooperation and communication with customers. Understanding customers' needs and providing customized solutions will meet customers' individual needs. The company's products are favored by customers for their high quality and reliability, and provide them with the best touchscreen panel solutions.

At DINGTOUCH, we are the world's leading touchscreen manufacturer, helping businesses around the world take advantage of this exciting technology. For more information, please visit the home page now.

Find the DINGTouch technical team to achieve the success of your company's new project.

How to choose touch screen customization?

DINGTouch is a company specializing in the R&D and production of touch screen technology, headquartered in Shenzhen, China. As a professional touch screen supplier, DINGTouch is committed to providing high-quality, stable and reliable touch screen products to meet the diverse needs of customers. We continue to carry out technological innovation and product optimization to ensure that its touch screen products have good sensitivity, accuracy and durability.

In addition to the products themselves, we also focus on cooperation and communication with customers, and are committed to providing customized solutions and excellent after-sales services. Through continuous efforts to improve product quality and customer satisfaction, we have established a good reputation in the touchscreen industry and won widespread market recognition.

What DINGTOUCH can do:

• PCAP maximum size 65”

• Multi-touch (Touch screen can be customized to your needs.)

• Optical bonding service/air bonding

• LCD interface: HDMI/RGB/MIPI/LVDS/EDP, etc.

• PCAP interface: IIC/USB interface

• CTP can customize the cover glass surface treatment process AG (anti-glare), AR (anti-reflection), AF (anti-fingerprint), waterproof, and glove touch

• Supports 0.55 mm-12 mm coverslip touch.

• Support operating temperature: -40℃-90℃.

Dingtouch Industrial Capacitive Touch Screen Manufacturer

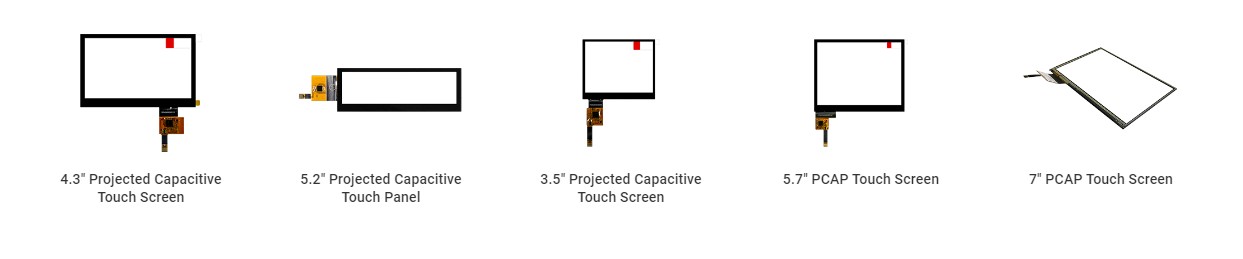

In conclusion, Dingtouch as a professional touch screen manufacturer with more than 10 years touch screen experience.We have many capacitive touch screen. Such as5 inch touch screen,7 inch touch screen,10.1inch touch screen,15 inch touch screen,15.6 inch touch screen,17 inch touch screen,18.5 inch touch screen,19 inch touch screen,21.5 inch touch screen,32 inch touch screen, However, we also welcome to customize your own touch screen . Contact our team today to learn what capacitive touch screen are best for our retail business needs.

Contact us NOW! sales@szdingtouch.com

CATEGORIES

CONTACT US

Contact: Dingtouch

Phone: +8615815536116

Tel: +8615815536116

Email: sales@szdingtouch.com

Add: Building A, Bailu Plaza, No. 48, Gonghe Industrial Road, Gongle Community, Xixiang Street, Baoan District, Shenzhen,China. 518126

Dingtouch

Dingtouch